R404A/R507A replacement Your main questions answered

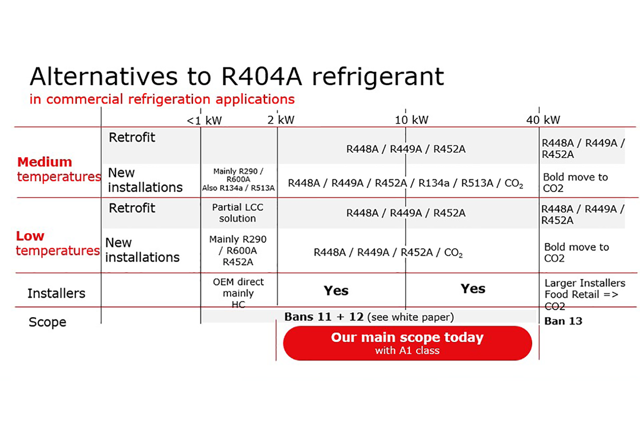

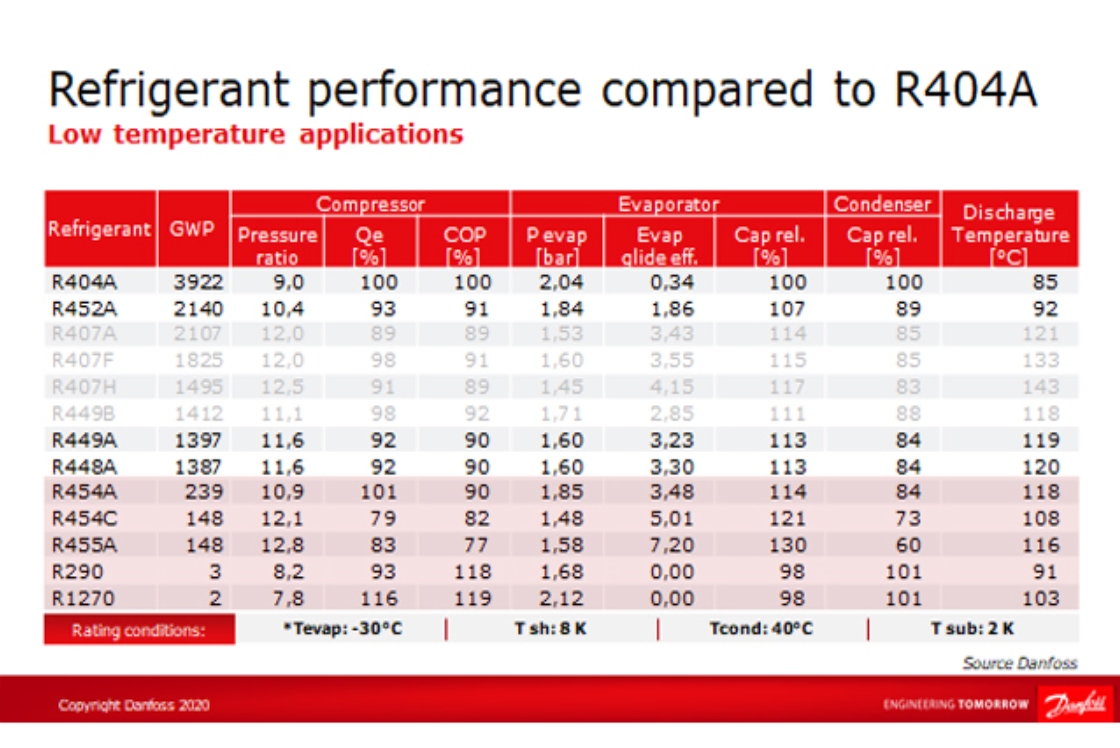

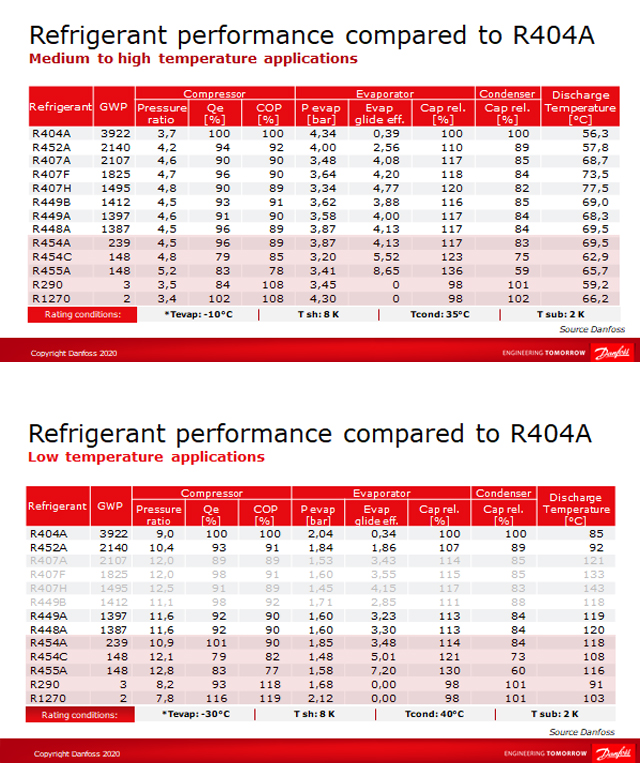

In Europe R404A and R507A refrigerants are already banned in many new refrigeration equipment and for service only recycled refrigerants can be used. Here is a list of replies to the many questions we have received related to the best refrigerants to replace R404A / R507A in refrigeration applications, to the impact on the system performance, on the components and their availability, and to the best practices.

Commercial Refrigeration applications are very diverse regarding systems types and refrigerants used. It includes cold rooms, glass door merchandisers, and display and islands cabinets, either in centralized or plug-ins – hermetic or autonomous cooling circuits with condensing units. Commercial Refrigeration applications are grouped into three main categories: hermetically sealed applications, condensing units and centralized DX systems.

Expert paper: Reducing the Global Warming Impact of Supermarket Refrigeration Systems

While Europe leads with CO2 refrigerants, other regions must urgently phase out high GWP gases like R-404A. Our expert paper provides insights and strategies to help you transition to natural refrigerants, boost energy efficiency, and improve maintenance practices. Read our expert paper to start the journey to make a positive environmental impact and enhance your operational resilience.

What are the best refrigerants to replace R404A in any application?

About component selection and best practices

Components qualified for new refrigerants