Fully-electric and hybrid EDITRON systems:

- Fully-electric and hybrid EDITRON systems

- Lower fuel and energy consumption

- Reduced carbon dioxide and small particle emissions

- Freedom of design thanks to lightweight and compact hardware

- Easy integration into various different machines

The future is electric. It’s in our DNA

With over 50 years’ history and experience, we are leading the electrification revolution. Around the world, our international teams are delivering the technology to enable a carbon-free future.

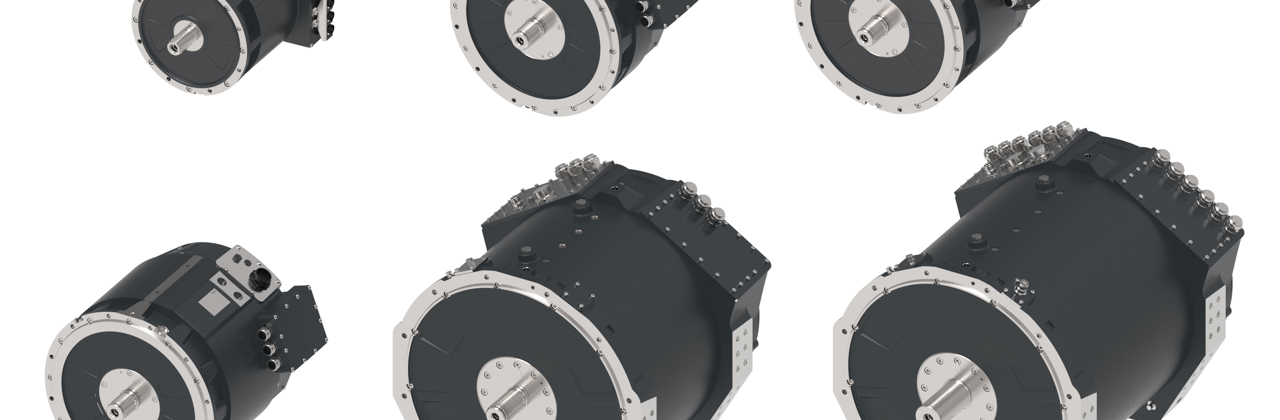

EDITRON is the world’s most sophisticated electric drivetrain system designed, manufactured and delivered by Danfoss Editron.

Our unique approach delivers maximum efficiencies, reduced size and weight, plus continual improvements for our customers. The sophisticated software behind our system controls and optimizes each individual component of an electric or hybrid drivetrain, leading to more intelligent management of power distribution.

The EDITRON system is comprised of components designed in-house with high IP-classes. In the marine market, it uses synchronous reluctance assisted permanent magnet technology on machines up to 6MW, while in off-highway and on-highway industries the power ranges from 30kW to 1000kW.

Related products

Case studies

-

if (isSmallPicture) {

Fundex Equipment electric foundation rig case story

Fundex Equipment electric foundation rig case storyWorld’s first fully electric large foundation rig with Danfoss Editron components.

-

if (isSmallPicture) {

Danfoss torque-limiting pump boosts productivity for truck-mounted electric crane

Danfoss torque-limiting pump boosts productivity for truck-mounted electric craneLearn how the Danfoss Series 45 ETL pump eliminated stalling, reduced costs, and delivered efficiency improvements for a truck-mounted crane produced by Türkiye-based OEM MPG.

-

if (isSmallPicture) {

Immersion cooling: Harnessing live-event technology in data centers

Immersion cooling: Harnessing live-event technology in data centersWhen COVID-19 wiped out festivals and live events, things were looking bleak for audio technology start-up iXora. With some help from Danfoss, the company realized that its cooling technology could be repurposed into a potentially game-changing solution for data centers.

-

if (isSmallPicture) {

Future-proof muscle control for Franna

Future-proof muscle control for FrannaNew Danfoss valve to control speed and power of hydraulic muscle in Australian manufacturer Franna’s cranes. “It’s extremely precise – definitely the best valve for the job,” Franna says.

-

if (isSmallPicture) {

Delivering the world's first fully-electric pile driving rig

Delivering the world's first fully-electric pile driving rigJunttan, a Finnish hydraulic piling equipment manufacturer, built the world’s first fully-electric pile driving rig in order to offer a sustainable option to their customers.

-

if (isSmallPicture) {

Smarter than the average skid steer

Smarter than the average skid steerA new generation of electric skid steer loaders is bringing smarter functionality to this important market segment, enhancing operator ease of use and productivity. Helping to facilitate this transition are intelligent electronic controls and software from Danfoss Power Solutions.

News

-

if (isSmallPicture) {

Danfoss Power Solutions celebrates 20th anniversary of flagship H1P pumpWednesday, June 18, 2025

Danfoss Power Solutions celebrates 20th anniversary of flagship H1P pumpWednesday, June 18, 2025The H1P axial piston pump is renowned for its unmatched reliability, high efficiency, compact design, and precise control. Danfoss has produced 1.7 million H1P pumps since its launch, and continues to invest in the portfolio today.

-

if (isSmallPicture) {

Drive performance, efficiency, and innovation with Danfoss at iVT Expo Cologne 2025Thursday, June 5, 2025

Drive performance, efficiency, and innovation with Danfoss at iVT Expo Cologne 2025Thursday, June 5, 2025Danfoss Power Solutions will highlight its latest technologies for off- and on-highway machinery at iVT Expo 2025, June 11-12, in Cologne, Germany. Visit the company at booth 2000.

-

if (isSmallPicture) {

Danfoss eHydraulic Power Module enables electrification of 200-tonne SANY crawler craneTuesday, May 13, 2025

Danfoss eHydraulic Power Module enables electrification of 200-tonne SANY crawler craneTuesday, May 13, 2025

Green energy transition towards a Fossil Free Future

Danfoss is leading a Fossil Free Future program which builds an ecosystem that drives intelligent, sustainable and cost-effective use of energy.