Non-toxic and mildly flammable, A2L refrigerants are gaining traction as a relatively easy way to further reduce global warming potential (GWP).

With the cooling industry successfully phasing down the use of higher GWP refrigerants, countless applications are now benefiting from refrigerants that are kinder to the environment. Now, the next step is to go further, and achieve ultra-low GWP.

Natural refrigerants like R290 and CO2 are being used for a wide range of applications. But for installers looking for a cost-effective option that maintains a conventional system design, A2L refrigerants are an excellent choice—offering a GWP saving of 90% and more.

Don’t be fooled by their flammability; with a few basic precautions, A2L refrigerants are safe and relatively easy to use. To give you the complete picture, here are our customers’ most frequently asked questions:

A2L refrigerants—the basics

What is A2L classification?

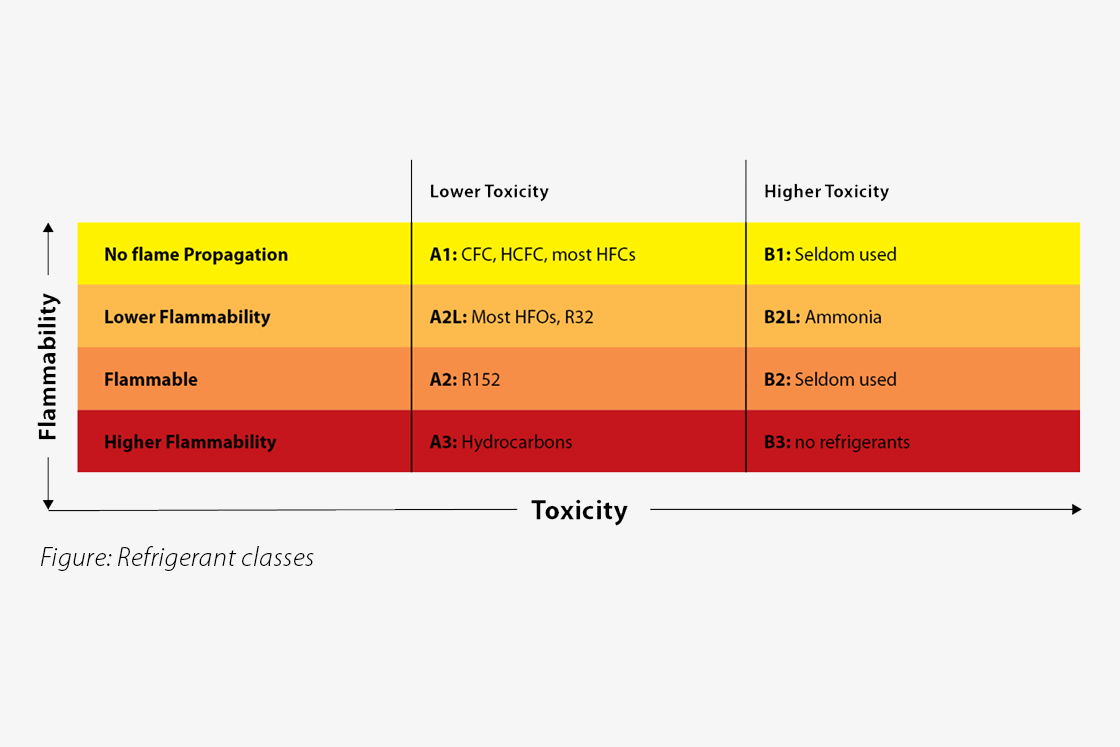

Like ASHRAE standard 34, standard ISO 817 “Refrigerants —Designation and safety classification” provides an unambiguous system for assigning designations to refrigerants’ toxicity and flammability.

In this case, A2L has lower flammability and toxicity compared to other classifications—making it the second safest refrigerant category.

A = Non-toxic

2 = Flammable

L = Low burning velocity

Which refrigerants are classed as A2L?

| R1234yf | GWP 4 |

| R1234ze | GWP 6 |

| R454C | GWP 146 |

| R455A | GWP 145 |

| R454A | GWP 238 |

| R454B | GWP 466 |

| R447A | GWP >500 |

| R32 | GWP 675 |

| R452B | GWP 676 |

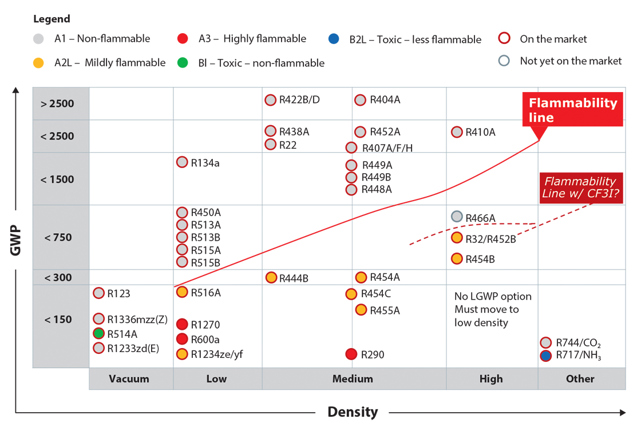

This chart shows how A2L refrigerants stack up against other refrigerant groups for GWP and density.

What are the major benefits of A2L refrigerants?

The primary benefit is on the GWP level. When compared to a popular refrigerant like R134a, an A2L refrigerant like the R1234yf offers up to 99% reduction in GWP. The very low or ultra-low GWP level makes A2Ls an attractive choice as regulations tighten further.

As their physical properties are similar to HFC refrigerants, they’re also relatively easy to use and don’t add any system complexity. Moreover, most of the tools installers are used to work with can be used with A2Ls as well.

Ultimately, being classed as “mildly flammable”, A2L refrigerants are a safe option for most refrigeration, air conditioning, and heat pump applications since they are difficult to ignite.

How do A2L refrigerants perform?

A2L refrigerants offer better performance and efficiency than many A1 and natural refrigerants—making them a versatile choice when used with the correct components and pipe sizes.

Working with A2L refrigerants—safety and risk mitigation

What does “mildly flammable” mean in practice?

A2L refrigerants need at least 1,000 times more energy to ignite than most A3-class flammable refrigerants.

It means that A2L refrigerants are unlikely to ignite from a discarded cigarette or a space heater. Even naked flames struggle to ignite A2L refrigerants under test conditions.

What’s more, the “L” means they have a low burning velocity. So, even in the event of ignition, the flame will likely burn slowly and self-extinguish.

What factors can cause A2L refrigerant to ignite?

For an A2L refrigerant to ignite, it needs to be highly concentrated. In practice, it would take a significant leak in an enclosed area to reach its lower flammability level of around 300g/m3.

The refrigerant also needs to be exposed to an open flame or high-energy source.

However, laboratory tests show that in most cases, even a blow torch flame struggles to ignite A2L refrigerants.

Are some A2L refrigerants more flammable than others?

Yes, there are different lower flammability limits and ignition energies, but they all fall into the same class: A2L.

What is a lower flammability limit?

Refrigerants need a certain concentration in air to generate a flammable mixture. The lowest flammable concentration is the lower flammability limit (LFL).

For A2L refrigerants, the LFL is greater than 100g/m3; typically, it’s above 300g/m3.

This means that for an A2L refrigerant to be flammable, its concentration needs to be ten times higher than for an A3 class refrigerant.

With simple risk mitigation factors such as adequate ventilation in confined spaces, the chances of igniting an A2L refrigerant become very low.

What safety precautions should I take?

While the risks of ignition are low, it’s important to remember that A2L refrigerants are still mildly flammable—and subject to safety regulations.

It’s critical to use properly qualified components. Danfoss Coolselector®2 is the quickest way of finding the right components for the right job.

There are also some charge limitations to be aware of. Users can apply A2L refrigerants up to 11kg with basic safety measures according standard EN 378-2, and up to 54kg with increased safety measures like leak detection.

If you’re unsure of the correct components, contact us for further expert advice.

Can a component failure, system leak, or electrical spark ignite an A2L refrigerant?

Let’s take the example of our new OptymaTM condensing units.

Using both computer modelling and real-world testing, we found no ignition occurred with Danfoss components used in a flammable environment.

But like any refrigeration system, it’s important to use the right components and charge limits to meet the safety rules for the application.

A2L applications and refrigerant selection

Does it matter which A2L refrigerant I use in a specific application?

Yes, depending on the application and operating conditions, you will need to select the right refrigerant. Indeed, in some cases, an A3 refrigerant might be a better choice.

Here are some examples:

- Mid-size, medium temperature systems 2 to 40 kW: R454C, R455C and R1234yf

- Smaller systems below 2 kW: R290 (A3 class)

Can I use A2L refrigerants in retrofit applications?

No. They must only be used in new systems.

What are the charge limits for A2L refrigerants?

This depends on the application. For example, the charge limit for an air conditioning application will be different than for a refrigeration system for a cold room.

EN378 also requires you to take system location into consideration, along with access and the room size. So, the charge limits for a confined indoor space will be different than for a cold room with a rooftop condensing unit.

By using a Micro Channel Heat Exchanger, you can significantly reduce charge—giving you greater flexibility with pipe runs, on cooling capacity, etc.

Watch our handy Charging of A2L Refrigerants explainer to learn how to calculate charge limits for different applications—including other critical distance and component calculations.

I’m worried that legislation will change again soon. How future-proof are A2L refrigerants?

We anticipate that A2L refrigerants are here to stay for a good while, so there’s never been a better time to transition.

To comply with the Kigali Amendment to the Montreal Protocol, the objective is a progressive reduction of 85% of CO2 equivalent emissions in 2036 and the EU F-GAS objective for fluorinated gases is only 79% in 2030

By balancing low GWP with mild flammability, A2L refrigerants can help you meet increasingly strict environmental regulations.

Why can’t I just use natural refrigerants like CO2 and R290?

Natural refrigerants offer an attractive long-term solution to refrigerant transition. But each brings its own challenges.

HCs require higher safety standards and bring limitations in refrigerant charge.

CO2 systems are somewhat more complex to use, with a different design architecture and higher operating pressures.

Both require additional knowledge and training.

External resources:

More about refrigerants

- Main refrigerants at play

- Natural refrigerants

- HFC replacements