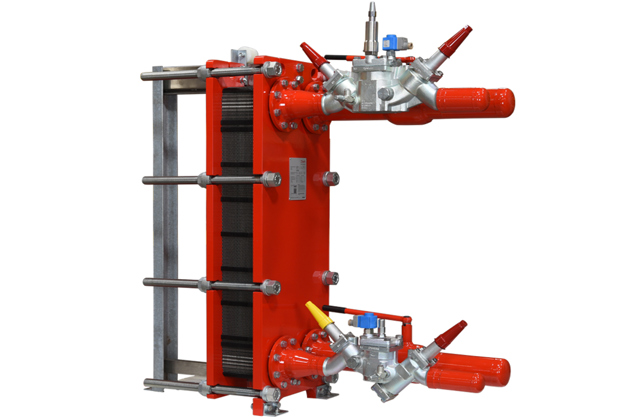

Our SONDEX® standard plate heat exchangers are the ideal choice for a wide range of applications across numerous market segments. Innovative technologies and smart design make our standard plate heat exchangers a stellar investment and the go-to choice for standard duties.

We have one of the largest plate portfolios in the world and we customize each heat exchanger to meet your exact requirements. The versatile design and high thermal efficiency make them the perfect solution for a wide range of applications.

Features and benefits

Experience the benefit of an individually customized solution that perfectly matches your requirements and lowers your energy consumption.

High performance for a low pressure drop eliminates unnecessary burdens on your system and optimizes overall system performance.

We design single-pass solutions when possible, as they are the preferred choice for almost all duties. With all connections on the head you do not need to disconnect the heat exchanger from the piping to perform inspection, cleaning, or service.

The design results in a compact solution with a small footprint, simple installation, and easy access for maintenance.

Discover how the SONDEX® gasketed plate heat exchanger operates.

From design and construction to working principles, we take you through the key features behind these high-efficiency heat transfer solutions.

Applications

- HVAC industry - e.g. district cooling solutions using seawater and groundwater as cooling source - e.g. district heating solutions using, for example, solar and geothermal energy as heating source

- Marine/offshore industry - e.g. central and lubrication oil cooling

- Dairy/food/beverage industry - e.g. pasteurization, heat recoveries, and duties that require gentle treatment

- Sugar industry

- Biogas industry

- Pulp and paper industry

- Heavy industry

- Mining industry

- Petrochemical industry

- Chemical industry - e.g. waste heat recovery from condenser water

Technical specifications

- Conections from DN25 to DN600 (1" to 24")

- Frames designed according to FEA and PED 2014/68/EU (EN13445) and ASME sec VIII, Div. 1 construction standards

- Plate materials: AISI 304/316, titanium, SMO, Hastelloy*

- Gasket materials: EPDM-HT, NBR-HT, Viton*

- Plate lengths up to 5.5 m (18 ft)

- Flow rates up to 7,200 m3/h (31,700 gpm)

- Working pressure up to 35 bar (500 psi)

- Working temperatures from -20 °C to 180 °C (-4 °F to 356 °F)

*Other materials are available upon request.

D-plate technology

Our Danfoss engineers have enhanced the way heat exchanger plates are designed with the introduction of the new D-plate series. Drawing on years of experience within heat transfer technology and deep application knowledge, we have made significant upgrades to the traditional Fishbone plates to truly redefine the way we think of heat exchanger plates.

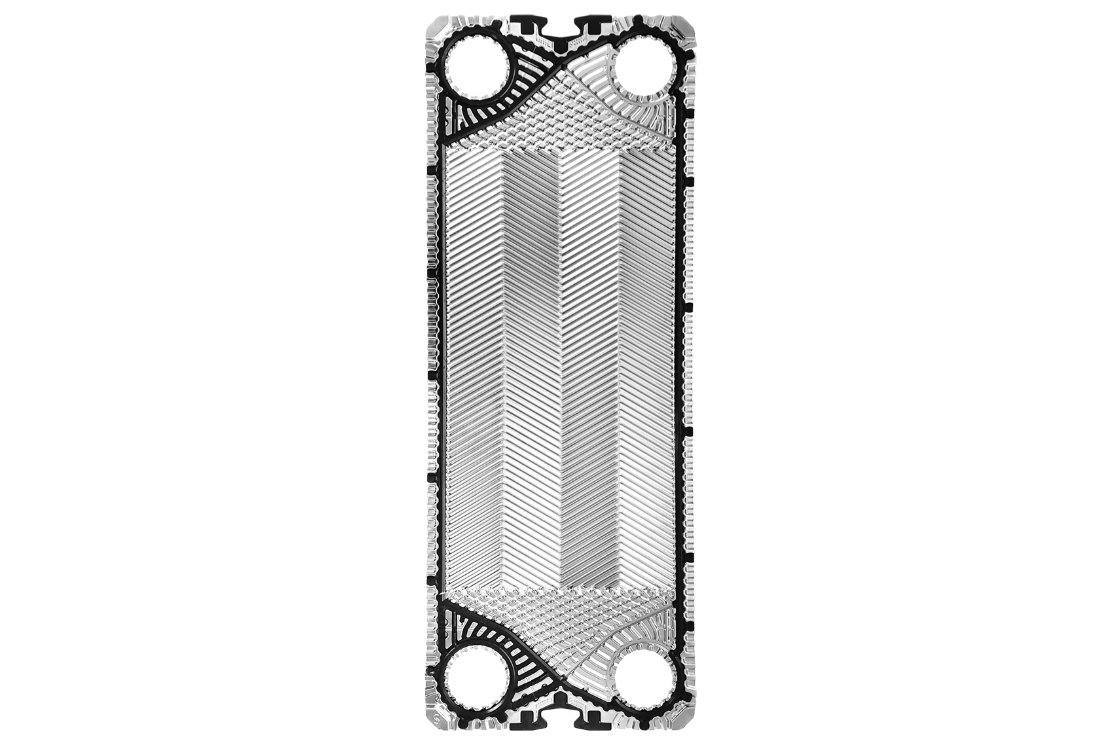

SONDEX® Fishbone plates

SONDEX® Fishbone plate pattern technology is used for the vast majority of our plate heat exchangers. The pattern is designed for high thermal performance while using the allowed pressure drop in the most efficient manner. Available with different pressing depths, pattern pitch and angles – each plate has a pattern that is optimized for a certain duty.

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Brochure | A world of heat exchangers | English | Multiple | 18 Nov, 2024 | 7.2 MB | |

| Brochure | A world of heat exchangers | Bulgarian | Bulgaria | 04 Oct, 2024 | 5.3 MB | |

| Brochure | A world of heat exchangers | Romanian, Moldavian, Moldovan | Romania | 10 Oct, 2024 | 9.7 MB | |

| Brochure | D-plate technology - Experience D-power | English | Multiple | 30 Jan, 2023 | 6.0 MB | |

| Brochure | Danfoss Design Code (DDC) | English | Multiple | 06 Sep, 2021 | 497.0 KB | |

| Brochure | Danfoss Design Code (DDC) | French | France | 29 Nov, 2021 | 302.6 KB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Polish | Multiple | 05 Jun, 2025 | 9.2 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | French | Multiple | 05 Jun, 2025 | 9.1 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Danish | Multiple | 05 Jun, 2025 | 9.1 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | German | Multiple | 05 Jun, 2025 | 9.2 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Chinese (CN) | Multiple | 05 Jun, 2025 | 9.6 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Hungarian | Multiple | 05 Jun, 2025 | 9.1 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Italian | Multiple | 05 Jun, 2025 | 9.1 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Russian | Multiple | 17 May, 2024 | 16.5 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | English | Multiple | 02 Jun, 2025 | 9.6 MB | |

| Brochure | Gasketed plate heat exchangers - Next-generation heat transfer solutions | English | Multiple | 22 Nov, 2024 | 4.4 MB | |

| Brochure | Heat exchangers for the power industry | English | Multiple | 19 Nov, 2024 | 4.8 MB | |

| Brochure | SONDEX® Free Flow sugar brochure | English | Multiple | 27 Nov, 2024 | 7.2 MB | |

| Brochure | SONDEX® Traditional Plate Heat Exchangers | English | Multiple | 12 Feb, 2024 | 9.4 MB |

Related products

-

if (isSmallPicture) {

Semi-welded plate heat exchanger for industrial refrigeration ammonia applications

Semi-welded plate heat exchanger for industrial refrigeration ammonia applicationsThe semi-welded plate heat exchangers are optimized for industrial applications. The semi-welded plate heat exchangers from Danfoss is designed for ammonia systems and can be used for applications such as Condensers, flooded and pumped evaporators, Sub-coolers, Desuperheaters and Oil coolers.

Case stories

-

if (isSmallPicture) {

Empowering geothermal expansion in Zakopane in Poland

Empowering geothermal expansion in Zakopane in PolandTogether with our long-term and trusted partner Geotermia Podhalańska in Poland, Danfoss Heat Exchangers is ready to take geothermal production to the next level.

-

if (isSmallPicture) {

New in-voyage ballast water treatment with Danfoss and Bawat

New in-voyage ballast water treatment with Danfoss and BawatWith the support of Danfoss heat exchangers and frequency converters, Bawat has devised a unique technology. It is simple and cost-efficient and will help shipowners treat their ballast water. No need for any chemicals, UV, filtering or post-treatment.

-

if (isSmallPicture) {

SONDEX® raises the standard in Brazil

SONDEX® raises the standard in BrazilSince its launch in 2016, the SONDEX® branch of Danfoss Brasil has worked hard to become the leading manufacturer of plate heat exchangers for customers across Latin America. In December 2017, the company took giant strides towards fulfilling its high ambitions when it delivered four evaporators to Bioenergética Aroeira for use in the production of sugarcane ethanol – the biggest delivery of its kind ever manufactured in Latin America.

-

if (isSmallPicture) {

Reduced energy consumption with new, optimized heat exchanger plates

Reduced energy consumption with new, optimized heat exchanger platesA major renovation project in AffaldVarme Aarhus, in collaboration with the Danfoss-owned company Sondex, has increased the efficiency of the heat exchangers by more than 20 percent by replacing old plates with new ones.

-

if (isSmallPicture) {

Danfoss ensured the right pool temperature at the right time

Danfoss ensured the right pool temperature at the right timeIn December 2017, the European Swimming Championships took place in the brand-new Royal Arena in Copenhagen. The arena normally hosts major names from the international music scene but for five days of competition, it was transformed into an international swim stadium.

Service

Gasketed plate heat exchanger service

Our service team offers repairs, trouble shooting, upgrades, and on-site cleaning and maintenance of your plate heat exchanger solution. We always utilize genuine spare parts both for SONDEX® heat exchangers and our selection of other heat exchanger brands.