Since its launch in 2016, the SONDEX® branch of Danfoss Brasil has worked hard to become the leading manufacturer of plate heat exchangers for customers across Latin America. In December 2017, the company took giant strides towards fulfilling its high ambitions when it delivered four evaporators to Bioenergética Aroeira for use in the production of sugarcane ethanol – the biggest delivery of its kind ever manufactured in Latin America.

SONDEX® fuels Brazil with sugarcane ethanol

The sugar industry is big business around the world – from South America to Asia – producing products such as refined sugar, molasses, and ethanol for use as viable biofuel. Brazil is the world’s largest producer of ethanol from sugarcanes with the company Bioenergética Aroeira being one of the leading sugar and ethanol manufacturers in the country – a market position that SONDEX® has helped achieve.

In recent years, there has been a growing demand for renewable and energy-efficient alternatives to traditional hydrocarbon-based fuels. The production and demand for ethanol has proven to be a viable, sustainable, and CO2-neutral alternative to traditional hydrocarbon-based fuels for the benefit of us all.

Therefore, it is no surprise that more and more companies are investing in their sugar production to lead the transition towards more renewable fuels – and one of the frontrunners is Bioenergética Aroeira.

The biggest delivery of its kind

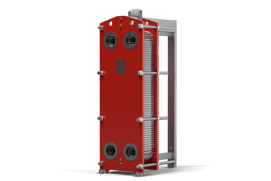

At the Bioenergética Aroeira plant, Danfoss Brasil has installed different types of SONDEX® plate heat exchangers for sugar production. In December 2017, four special evaporators, type SEC174, were installed, which was the biggest delivery of its kind ever manufactured in Latin America.

Prior to the record-breaking installation, the SONDEX® branch of Danfoss Brasil had proven to be a reliable and innovative partner with the delivery of four SF131 Free Flow plate heat exchangers, one SF101 Free Flow plate heat exchanger, and one S100 traditional plate heat exchanger. They were all up and running through the full 2017 season and are now in operation for the 2018 season, with high customer satisfaction, which leaves no doubt that the cooperation with Danfoss Brasil is fruitful:

“Fact is, we are pleased with our technical partnership with the SONDEX® branch of Danfoss Brasil. By utilizing the leading technology from SONDEX®, we now have an excellent solution that will help us save energy,” explains Dr. José Rubens Bevilacqua, CEO, Bioenergética Aroeira, who continues:

“The SONDEX® plate evaporators will help us reduce our steam consumption by 20%. This will have a positive financial impact on our business, so we expect the new evaporators to pay for themselves in just three years.”

SONDEX® products offer a wide range of benefits

Gentle treatment and even distribution of the media provide the highest possible product quality

High heat transfer efficiency and extended intervals between service ensure operation for an entire campaign with minimum downtime and maximum value for money

Large plate gap designed to combat fouling with sizeable plate channels and no stagnant zones

Related products

-

if (isSmallPicture) {

Standard plate heat exchangers

Standard plate heat exchangersSONDEX® standard plate heat exchangers are the ideal choice for a wide range of applications across numerous market segments. We have the largest plate portfolio in the world, and customize each heat exchanger to meet your exact requirements. Innovative technologies and smart design make our traditional plate heat exchangers a stellar investment.

-

if (isSmallPicture) {

Free Flow plate heat exchangers

Free Flow plate heat exchangersSONDEX® Free Flow plate heat exchangers are the preferred choice for applications that use media with particle-rich contents, fouling tendency, or high viscosity. Each Free Flow heat exchanger is customized to suit your application and media type, with contact-free plate channels for an unimpeded flow and long intervals between cleaning.