Localized service and maintenance – always

available near you!

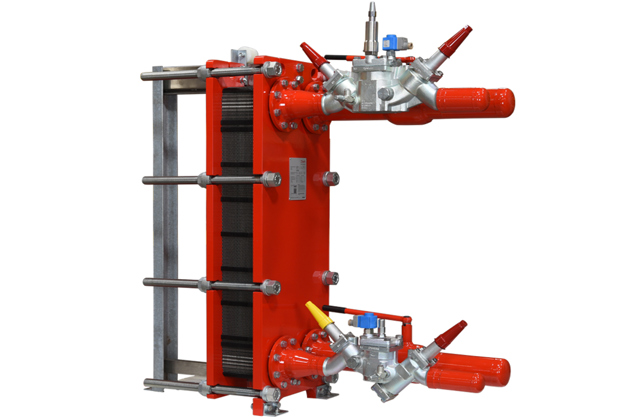

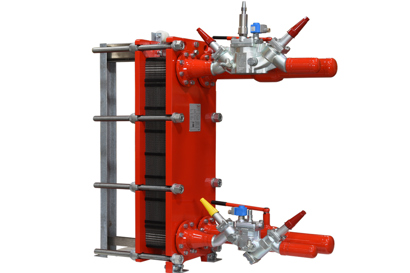

Our service team offers repairs, trouble shooting, upgrades, and on-site

cleaning and maintenance of your plate heat exchanger solution.

We always utilize genuine spare parts both for SONDEX® heat exchangers

and our selection of other heat exchanger brands.

Let our highly skilled experts support you avoiding problems before they

arise due to our customized program, ranging from full maintenance

support to ad hoc servicing.

At your convenience!

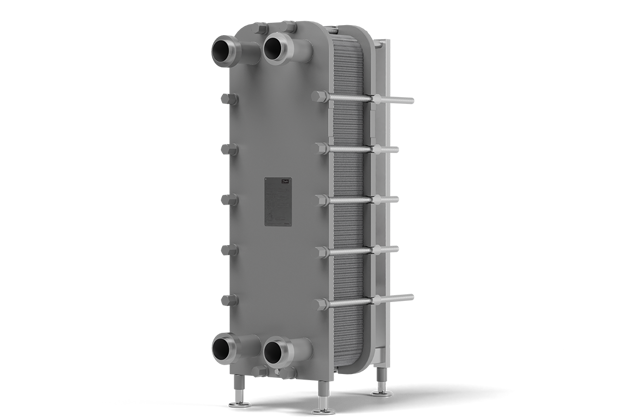

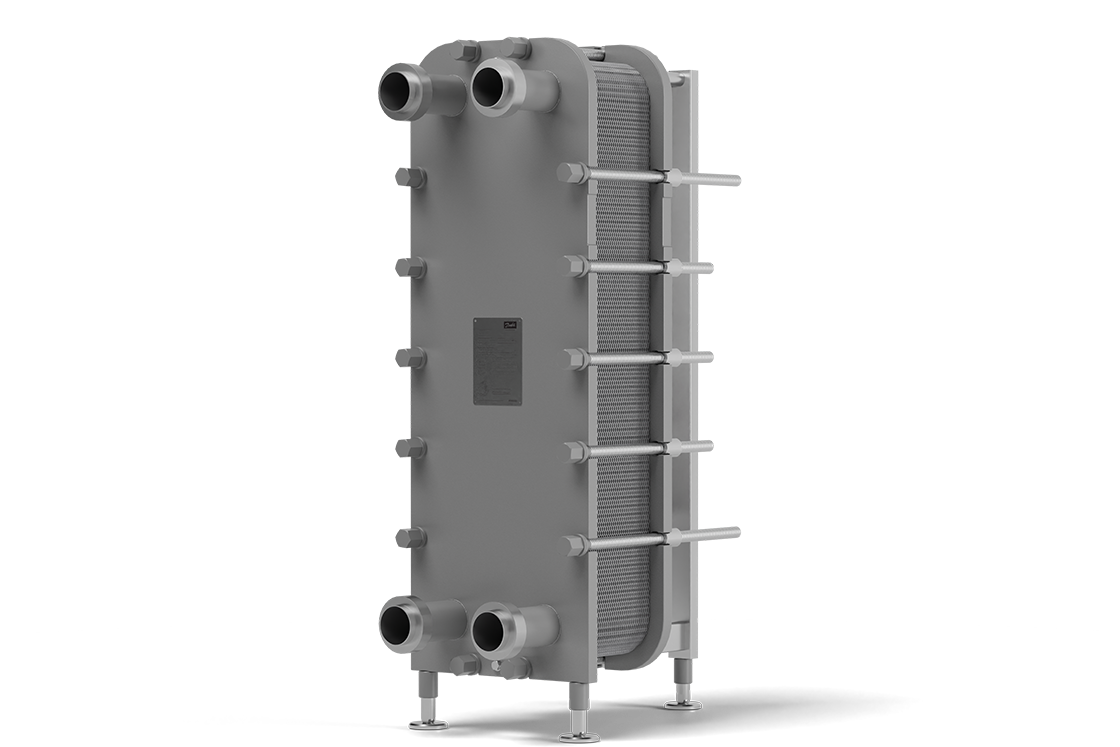

We will work out the most convenient schedule with you to carry out performance diagnostics, plate cleaning and inspections, fault checking with quick replacements, and repairs as required and needed. Our skilled technicians will clean your heat exchangers using environmentally friendly, economical

methods, and we will have your heat exchanger up and running at full capacity as soon as possible. Always keeping your process priority in mind.

We are fully equipped to also perform CIP (Cleaning in Place) where possible and at your request.

Replacement with genuine spare parts

If your plate heat exchanger is malfunctioning or underperforming, our repair service teams will immediately restore your installation to working order.

We replace worn gaskets and damaged or leaking plates with genuine spare parts that match the original specifications of your solution.

Genuine spare parts are essential to the performance and lifecycle of the heat exchanger together with the quality and warranty of your heat exchanger.

Depending on the operating dependencies of the heat exchanger, it is recommended to have a set of genuine spare parts on-site to reduce unexpected

downtime.

360-degree analysis of your solution

We also offer to analyze your current setup to determine if the solution can be optimized, for example, by increasing the number of plates in the heat

exchanger. This is an upgrade of your entire system, as more efficient heat exchangers improve the overall performance while reducing the energy

consumption, thus minimizing your carbon footprint, and not least decreasing your costs

Avoid system failure and shutdowns!

Regular maintenance ensures high performance and low

operating costs - a clean heat exchanger reduces the energy

consumption significantly.

Get in touch today to get a non-binding offer on your next

heat exchanger service.

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Polish | Multiple | 05 Jun, 2025 | 9.2 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | French | Multiple | 05 Jun, 2025 | 9.1 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Danish | Multiple | 05 Jun, 2025 | 9.1 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | German | Multiple | 05 Jun, 2025 | 9.2 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Chinese (CN) | Multiple | 05 Jun, 2025 | 9.6 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Hungarian | Multiple | 05 Jun, 2025 | 9.1 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Italian | Multiple | 05 Jun, 2025 | 9.1 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Russian | Multiple | 17 May, 2024 | 16.5 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | English | Multiple | 02 Jun, 2025 | 9.6 MB | |

| Brochure | Gasketed heat exchanger service - always available near you | English | Multiple | 24 Feb, 2023 | 1.8 MB |

Related products

-

if (isSmallPicture) {

Sanitary plate heat exchangers

Sanitary plate heat exchangersSONDEX® sanitary plate heat exchangers are made for applications with strict hygienic requirements and use FDA compliant materials. We care greatly about your end product, and take the necessary steps to ensure the highest output quality. Each solution is designed based on your specifications to provide the perfect conditions for your product.

-

if (isSmallPicture) {

Standard plate heat exchangers

Standard plate heat exchangersSONDEX® standard plate heat exchangers are the ideal choice for a wide range of applications across numerous market segments. We have the largest plate portfolio in the world, and customize each heat exchanger to meet your exact requirements. Innovative technologies and smart design make our traditional plate heat exchangers a stellar investment.

-

if (isSmallPicture) {

Free Flow plate heat exchangers

Free Flow plate heat exchangersSONDEX® Free Flow plate heat exchangers are the preferred choice for applications that use media with particle-rich contents, fouling tendency, or high viscosity. Each Free Flow heat exchanger is customized to suit your application and media type, with contact-free plate channels for an unimpeded flow and long intervals between cleaning.

-

if (isSmallPicture) {

Semi-welded plate heat exchanger for industrial refrigeration ammonia applications

Semi-welded plate heat exchanger for industrial refrigeration ammonia applicationsThe semi-welded plate heat exchangers are optimized for industrial applications. The semi-welded plate heat exchangers from Danfoss is designed for ammonia systems and can be used for applications such as Condensers, flooded and pumped evaporators, Sub-coolers, Desuperheaters and Oil coolers.