Meet application needs with maximum performance

Our semi-welded plate heat exchangers are optimized for industrial applications and include extensive improvements in professional refrigeration. The semi-welded plate heat exchangers from Danfoss is designed for natural refrigerant applications and can be used for applications such as Condensers, flooded and pumped evaporators, Sub-coolers, Desuperheaters, Superheaters, Economizers and Oil coolers. The product range includes the sizes SW19-SW59, with more to come, and can handle temperatures ranging from -40°C up to 150°C (-40°F up to 302°F) and pressure ranges up to 40 bar (300 psi).

View the 3D model

Features and benefits

Excellent heat transfer capabilities

Reliable design - operational safety

Easy product configuration

Comprehensive testing

Part of diversified product range for IR systems

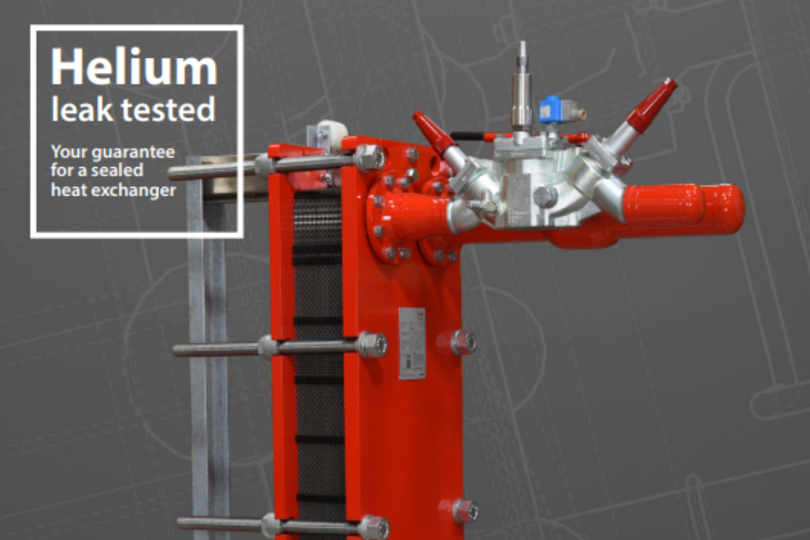

Comprehensive HE2 leak testing

Optimization of overall system design

Danfoss system control experts

High quality product - fully tested

The Danfoss semi-welded plate heat exchanger design has been verified through thermal and mechanical tests. Furthermore, each semi-welded plate cassette and fully assembled plate heat exchanger are thoroughly leak tested with helium before they leave the Danfoss factory.

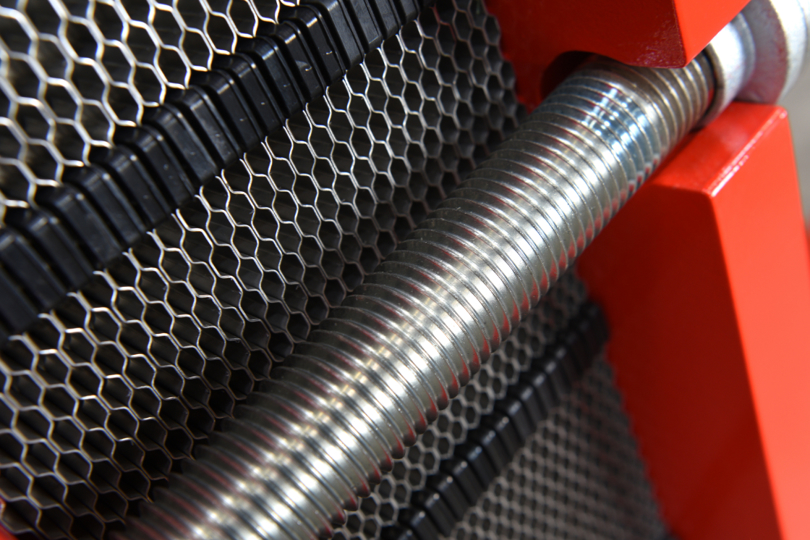

New plate design delivers excellent heat transfer capabilities

The SW19-59 range features excellent heat transfer capabilities via improved thermal performance due to optimized plate geometry supporting high turbulent natural refrigerant flow enabling a compact design and supporting lower charge for your refrigeration.

New gasket system improves plate pack stability and safety

The new gasket system ensures high gasket stability and optimal plate alignment due to new gasket and gasket grove design, enabling easy and fast service and maintenance. The new design improves the sealing effect and prevents gasket-blow out. Furthermore, the risk of contamination is reduced due to the double gasket barrier that will drain potential leakages outside of the plate pack. The new gasket system is glue free for easy maintenance.

Easy maintenance and service

The new range is easy to service and maintain. Easy access to the plate pack with the non-corrosive nylon roller that makes it easy to slide the follower along the carrying bar. Assembly of the plate heat exchanger is fast and safe thanks to fixed bolt heads and lock bushes which prevent the nut and bolt head from rotating when opening and closing the unit. The enhanced gasket system ensures easy and precise plate pack alignment.

Availability

Our line of Semi-welded plate heat exchangers is available now around the world from our factories in the USA, China, and Europe. Reach out to your local representative.

Watch video

The new series of plate heat exchangers has been optimized for industrial applications and include improvements to both plate design and the gasket system.

Download brochure

The new series of semi-welded plate heat exchangers has been optimized for industrial applications and include improvements to both plate design and the gasket system.

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Brochure | A world of heat exchangers | English | Multiple | 18 Nov, 2024 | 7.2 MB | |

| Brochure | A world of heat exchangers | Bulgarian | Bulgaria | 04 Oct, 2024 | 5.3 MB | |

| Brochure | A world of heat exchangers | Romanian, Moldavian, Moldovan | Romania | 10 Oct, 2024 | 9.7 MB | |

| Case story | Danfoss semi-welded plate evaporator and air purger applications at the automated cold storage Miratorg | English | Multiple | 01 Jun, 2021 | 3.1 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Polish | Multiple | 05 Jun, 2025 | 9.2 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | French | Multiple | 05 Jun, 2025 | 9.1 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Danish | Multiple | 05 Jun, 2025 | 9.1 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | German | Multiple | 05 Jun, 2025 | 9.2 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Chinese (CN) | Multiple | 05 Jun, 2025 | 9.6 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Hungarian | Multiple | 05 Jun, 2025 | 9.1 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Italian | Multiple | 05 Jun, 2025 | 9.1 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Russian | Multiple | 17 May, 2024 | 16.5 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | English | Multiple | 02 Jun, 2025 | 9.6 MB | |

| Brochure | Gasketed plate heat exchangers - Next-generation heat transfer solutions | English | Multiple | 22 Nov, 2024 | 4.4 MB | |

| User guide | Plate Type Heat Exchangers, Single plate and Semi-welded Installation, Commissioning and Maintenance | Italian | Multiple | 23 Jul, 2019 | 6.2 MB | |

| User guide | Plate Type Heat Exchangers, Single plate and Semi-welded Installation, Commissioning and Maintenance | Russian | Multiple | 23 Jul, 2019 | 6.2 MB | |

| User guide | Plate Type Heat Exchangers, Single plate and Semi-welded Installation, Commissioning and Maintenance | German | Multiple | 23 Jul, 2019 | 6.2 MB | |

| User guide | Plate Type Heat Exchangers, Single plate and Semi-welded Installation, Commissioning and Maintenance | English | Multiple | 23 Jul, 2019 | 6.2 MB | |

| User guide | Plate Type Heat Exchangers, Single plate and Semi-welded Installation, Commissioning and Maintenance | Portuguese | Multiple | 23 Jul, 2019 | 6.2 MB | |

| User guide | Plate Type Heat Exchangers, Single plate and Semi-welded Installation, Commissioning and Maintenance | Danish | Multiple | 23 Jul, 2019 | 6.2 MB | |

| User guide | Plate Type Heat Exchangers, Single plate and Semi-welded Installation, Commissioning and Maintenance | French | Multiple | 23 Jul, 2019 | 6.2 MB | |

| User guide | Plate Type Heat Exchangers, Single plate and Semi-welded Installation, Commissioning and Maintenance | Chinese (CN) | Multiple | 23 Jul, 2019 | 6.7 MB | |

| User guide | Plate Type Heat Exchangers, Single plate and Semi-welded Installation, Commissioning and Maintenance | Polish | Multiple | 23 Jul, 2019 | 6.2 MB | |

| User guide | Plate Type Heat Exchangers, Single plate and Semi-welded Installation, Commissioning and Maintenance | Spanish, Castilian | Multiple | 23 Jul, 2019 | 6.2 MB | |

| Brochure | Semi-welded plate heat exchanger | Danish | Denmark | 24 Apr, 2019 | 2.8 MB | |

| Brochure | Semi-welded plate heat exchanger | Czech | Czech Republic | 09 Jun, 2021 | 3.5 MB | |

| Brochure | Semi-welded plate heat exchanger | Vietnamese | Vietnam | 22 Nov, 2019 | 9.0 MB | |

| Brochure | Semi-welded plate heat exchanger | Hungarian | Hungary | 17 May, 2021 | 2.8 MB | |

| Brochure | Semi-welded plate heat exchanger | Swedish | Sweden | 14 Mar, 2019 | 2.8 MB | |

| Brochure | Semi-welded plate heat exchanger | English | Multiple | 19 Sep, 2023 | 4.2 MB | |

| Brochure | Semi-welded plate heat exchanger | Finnish | Finland | 14 Mar, 2019 | 2.8 MB | |

| Brochure | Semi-welded plate heat exchanger | Polish | Poland | 06 Aug, 2019 | 2.8 MB | |

| Brochure | Semi-welded plate heat exchanger | Portuguese | Portugal | 06 Aug, 2019 | 2.7 MB | |

| Brochure | Semi-welded plate heat exchanger | Spanish, Castilian | Spain | 05 Mar, 2019 | 8.9 MB | |

| Brochure | Semi-welded plate heat exchanger | Italian | Italy | 04 Mar, 2019 | 8.8 MB | |

| Brochure | Semi-welded plate heat exchanger | French | France | 04 Mar, 2019 | 8.9 MB | |

| Brochure | Semi-welded plate heat exchanger | Turkish | Turkey | 06 Aug, 2019 | 2.8 MB | |

| Brochure | Semi-welded plate heat exchanger | German | Germany | 08 Oct, 2019 | 8.4 MB | |

| Brochure | SONDEX® Semi-Welded Heat Exchangers | English | Multiple | 27 Nov, 2024 | 3.5 MB | |

| Brochure | SONDEX® Traditional Plate Heat Exchangers | English | Multiple | 12 Feb, 2024 | 9.4 MB | |

| Brochure | Полусварные пластинчатые теплообменники | Russian | Multiple | 07 May, 2019 | 2.8 MB |

Related products

-

if (isSmallPicture) {

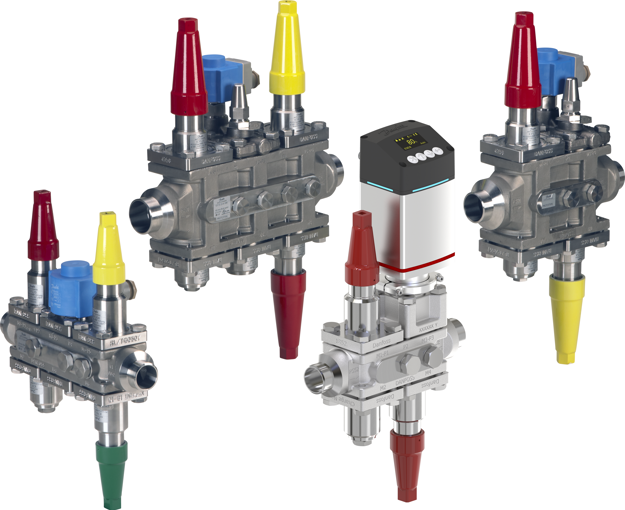

ICV Flexline™ with flanges

ICV Flexline™ with flangesThe ICV with flanges is available in five sizes: ICV 25 PM, ICV 35 PM, ICV 40 PM, ICV 50 PM and ICV 65 PM.

-

if (isSmallPicture) {

ICF Flexline™ stainless steel valve station

ICF Flexline™ stainless steel valve stationThe ICF SS valve station offer savings in time, space and money compared to control solutions using conventional components.

-

if (isSmallPicture) {

Pilot valves for ICS Flexline™

Pilot valves for ICS Flexline™The extensive range of Danfoss pilot valves include: Constant-pressure pilot valve, type CVP Differential-pressure pilot valve, type CVPP Pressure-operated pilot valve with reference pressure connection, type CVC Electronically operated constant-pressure pilot valve, type CVE Solenoid pilot valve, type EVM (NC) Solenoid pilot valve, type EVM (NO) Housing, type CVH for pilot valves, for mounting in external pilot lines.

-

if (isSmallPicture) {

ICF Flexline™ 50-65 valves

ICF Flexline™ 50-65 valvesThe ICF valve station offer savings in time, space and money compared to control solutions using conventional components. The ICF valve station incorporates several functions in one control body.

-

if (isSmallPicture) {

SVL Flexline™

SVL Flexline™SVL Flexline™ product platform targeted to meet industrial refrigeration requirements. The range cover five different functions with just two valve models.