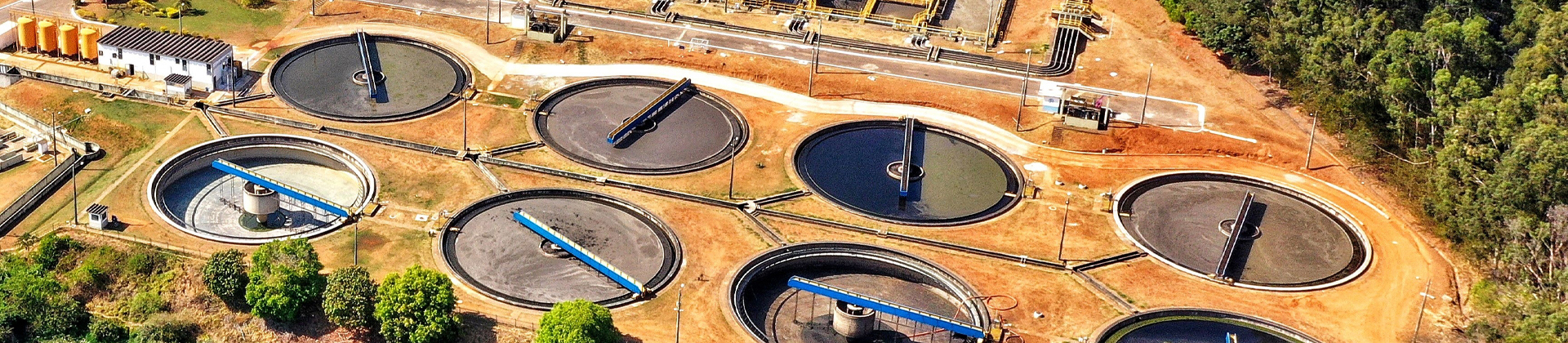

BRAZIL: CAESB is the public sanitation company responsible for both water supply and wastewater treatment for over 3 million people in Brazil’s Federal District — home to the capital Brasília. Here there is no room for errors. Unexpected pump failures can lead to raw sewage spilling into nearby lakes — creating hazardous conditions. But with many units running for more than 11 years, the risk of breakdowns was rising. Without action, failures could interrupt service and harm the environment.

Building on 15 years of collaboration, CAESB brought Danfoss even closer with a tailored service program designed specifically for the demands of their water supply and wastewater infrastructure.

The challenge: Predictable water management

After operating more than 500 drives for over a decade across their integrated water and wastewater operations, CAESB began to face challenges in creating predictability — both in terms of technical uptime and cost. The drives were running under harsh environmental conditions and high mechanical load, which caused some units to show signs of wear and increased the risk of breakdowns. Moreover, with limited tools for predictive maintenance and structured spare parts planning, CAESB also faced difficulties in maintaining full visibility and control over the system.

The solution: DrivePro® maintenance and ultra low-harmonic iC7 drives

Danfoss developed a solution for CAESB rooted in their fundamental belief that effective service must be tailored to each customer’s unique context.

The solution includes DrivePro® Start-up, to secure proper commissioning and long-term performance of newly installed drives. DrivePro® Preventive Maintenance provides custom plans and early fault detection by certified Danfoss experts to keep CAESB’s systems running reliably. The package also includes DrivePro® Spare Parts, ensuring fast access to original components precisely matched to CAESB’s drives for seamless replacement.

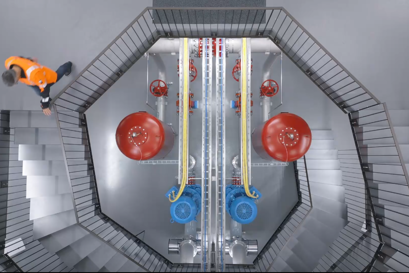

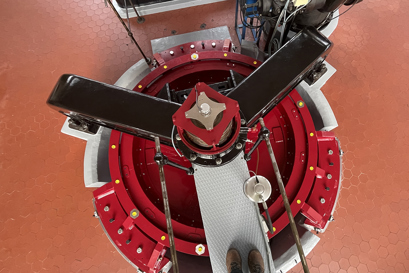

To further reduce downtime, 17 high-power VLT® AQUA Drive FC 202 and several VLT Soft Starter MCD 600 units were refurbished as part of a corrective maintenance solution — a service element added specifically to match CAESB’s need for restoring ageing, high-load units critical to operations.

Ultra low-harmonic (ULH) protection

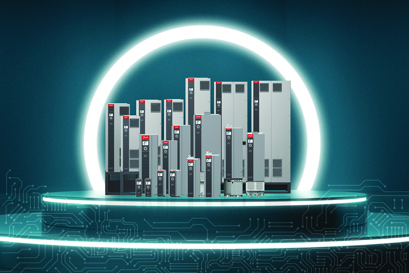

In parallel with the service agreement, CAESB also began upgrading to the next-generation iC7 series ULH drives, also known as AFE — selected specifically to mitigate harmonic distortion, improve power quality, and protect critical infrastructure.

The outcome: More control, less risk

With the two-year tailored service program, CAESB now benefits from reliable, planned maintenance and a guaranteed response time to improve predictability. Refurbished drives and upgraded units have extended the lifetime of their equipment, reduced the risk of downtime, and brought control to both operations and budgets.

Most importantly, CAESB gained peace of mind, knowing their infrastructure is now supported by dependable products and a long-term partner focused on keeping Brazil’s capital running.

By engaging early and focusing on what truly matters, we were able to design a solution that met CAESB’s specific needs and positioned us as a true partner in their success.

Danfoss products and services in this project

For high-end applications that always deliver, you need compact drives that place versatile, intelligent technology at the heart of your operations. Groundbreaking AC drives designed for excellence — by providing more power and precision than ever before.

More case stories

Brazilian water utility CAESB relies on DrivePro® services for planned maintenance and guaranteed response time to improve predictability in water management. Refurbished drives and upgraded units have extended the lifetime of their equipment, reduced the risk of downtime, and brought control to both operations and budgets.

CZECHIA: When 80-year-old gears were replaced by variable speed control at the Albrechtice hydropower plant, power production increased by 10%.

CHINA: Thanks to several Danfoss DrivePro® services, Dahe Paper Group, a state-owned paper mill company in China, has reduced its costs, downtime, and failure rate.

Belgium: Thanks to Danfoss DrivePro® services, LuxFly has achieved 99,5% uptime in Europe’s largest vertical wind tunnel that is used for skydiving.