SWITZERLAND: We take it for granted that sufficient drinking water is available at all times. Constantly vigilant, local water suppliers meet this expectation by providing drinking water of the highest quality on a continuous basis. In the canton of Bern, the water association Region Bern AG (WVRB) supplies a community of more than 250,000 inhabitants with 20.9 million cubic meters of drinking water per year. The sophisticated drinking water treatment plant and distribution system consists of water pumping stations, collection basins, connecting lines and a storage reservoir.

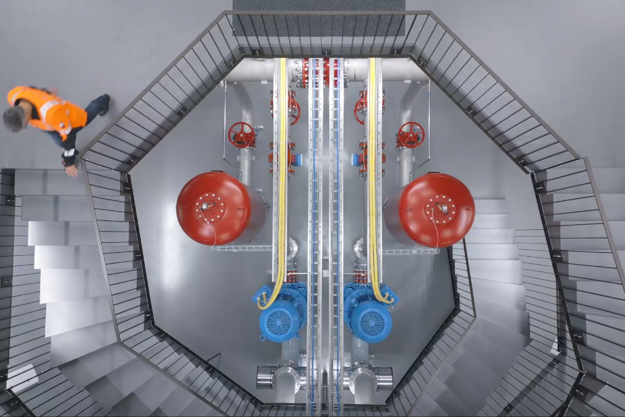

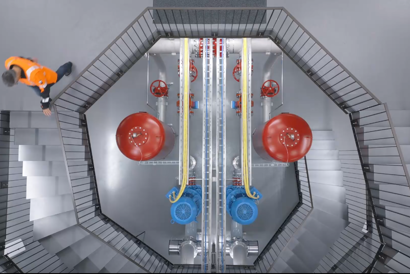

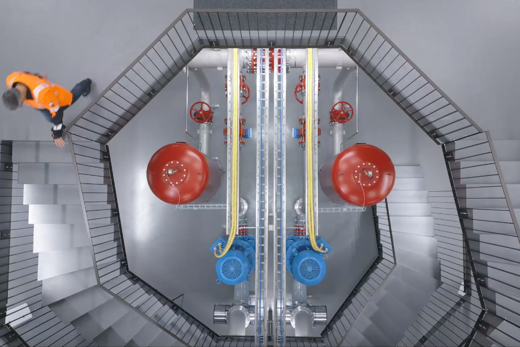

To ensure a reliable, high quality water supply, the WVRB is constantly investing in the latest technology. As part of these efforts, they commissioned the new Wehrliau pumping station in 2023. It will help to ensure reliable quantity and quality of drinking water supply to the communities in the Canton of Bern for many years to come. The Wehrliau pumping station delivers up to 20,000 liters of drinking water per minute – that’s as much as 130 full bathtubs. Two pumps, each driven by speed-regulated 250 kW electric motors, transfer water from two local drinking water wells into the new pump station and then feed it into the municipal supply network.

The challenge: Uninterrupted pumping station availablility

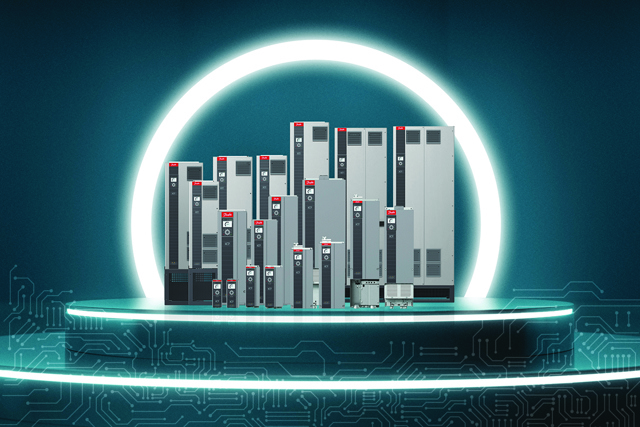

System availability in the water pumping station is crucial for an uninterrupted supply of clean drinking water. Variable speed control must function with absolute reliability and optimal efficiency. Efficient and straightforward maintenance options play an important role here. High system efficiency also avoids water waste, limits energy losses and reduces CO2 emissions. iC7 drives from Danfoss play a key role in ensuring optimal variable speed control in the system. They reliably adapt the amount of water to meet the community’s drinking water requirements.

The solution: Harmonic-free water pumping station

Using iC7 drives, Danfoss worked with service partner Gebrüder Meier to develop a solution that ensures uninterrupted operation of the pumping station, as well as legal compliance regarding harmonic mitigation. The Danfoss solution eliminates harmonics causing mains distortion as far as possible, to ensure a clean grid.

The iC7 drive has a modular architecture. Using a low-harmonic front-end based on AFE technology, the drive ensures optimum performance and minimizes harmonic distortion in the mains power supply. The inverter controls the motor and the load of the application.

Danfoss was able to meet the requirement for local installation in the water pumping station by designing the drives as a complete solution with integrated cooling and ventilation in a Rittal cabinet system. Installation close to the motor avoids negative influences on the motor voltage and makes it possible to dispense with additional output filters.

When it comes to variable speed drives, we have opted for Danfoss, because Danfoss fulfills our expectations very well. We want to install our drives as close to the motor as possible. Danfoss also gives us the opportunity to set up the electrotechnical interfaces, the signal interfaces, exactly as we want them.

The outcome: iC7 series saves space

As with any high-power drive application, space in the Wehrliau pumping station is extremely limited. Compared with similar drives in the market, compact iC7 drives have a 30% smaller footprint. Furthermore, the water federation saved on installation costs by wiring the drives from above, with no need to open the base plate.

The control cabinet employs a natural air-cooling system. Each module is self-ventilating by drawing in cool air from below and directing warm air out of the cabinet. This eliminates the need for a fan on the top of the cabinet, saving energy, avoiding possible failures and reducing spare parts. In addition, this solution improves the lifetime of the equipment by eliminating hot air immediately. Hot air will shorten component lifespan if allowed to linger inside the cabinet.

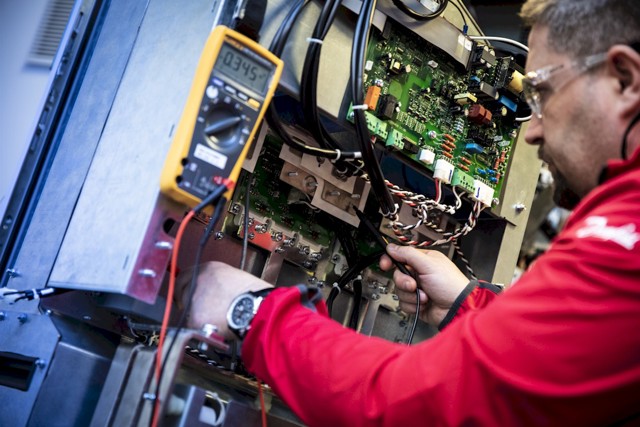

During commissioning, maintenance and service, iC7 drives enable safe and easy access to all major assemblies and components. The door-in-door concept ensures better personal safety for our maintenance and service personnel, giving us safe access to the control electronics during operation. The power electronics are safely hidden behind the cabinet door, eliminating the risk of injury or contact with live parts. For added convenience, the integrated fold-out service table allows us to keep a laptop handy, ready to edit drive parameters using the MyDrive Insight PC tool.

Fast and safe pumping station maintenance

As well as optimizing system availability and efficiency, the water supplier benefits from safe and convenient maintenance when required. For example, the power modules can be replaced individually without having to disconnect mains and motor cables. This makes maintenance and replacement much easier and faster. The fan cassettes, typical wear parts in such applications, can also be cleaned or replaced quickly and easily. Maintenance time here is reduced from several hours to just a few minutes.

|

Installation information

|

How close cooperation contributed to the success of the project

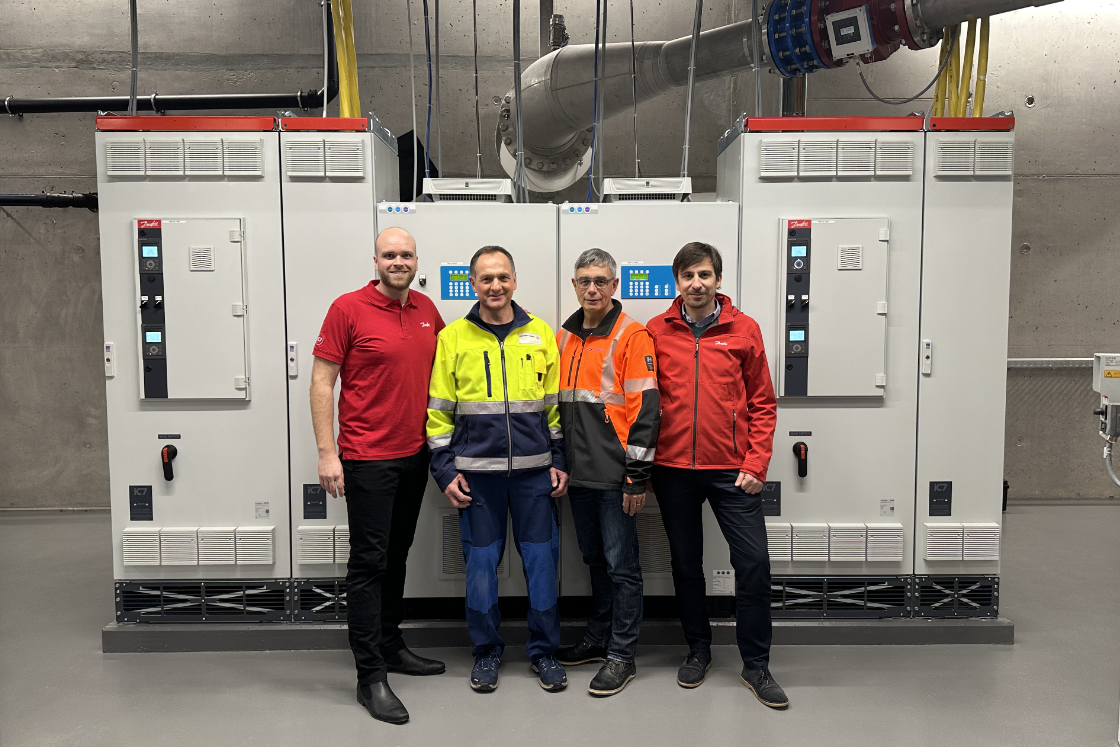

Throughout the project, the water association Region Bern worked closely with Danfoss and its service partner Gebrüder Meier. Close cooperation between the water association, the Danfoss plant, product development and Danfoss service made it possible to meet all the requirements in this infrastructure project, which is important for the region.

Gebrüder Meier provided the DrivePro® Start-Up service, to optimize commissioning. On an ongoing basis, they will continue to optimize running costs of the water network, using DrivePro® service offerings to ensure precisely the service and support that the WVRB requires for safe and reliable operation throughout the entire life cycle of the devices. This ranges from initial selection and commissioning to modernization by retrofit at the end of the long service life.

Danfoss products and services in this project

Related case stories

-

if (isSmallPicture) {

How a new water pumping station keeps supply flowing in Bern

How a new water pumping station keeps supply flowing in BernSWITZERLAND: The Wehrliau pumping station in Bern delivers up to 1.20 M liters of drinking water hourly. iC7 drives play a key role in ensuring reliable supply.

-

if (isSmallPicture) {

Bringing clean drinking water to rural Kenya with 100% renewable resources

Bringing clean drinking water to rural Kenya with 100% renewable resourcesKENYA: A solar-powered desalination plant in Kenya gives the community affordable, clean, and sustainable drinking water and irrigation water.

-

if (isSmallPicture) {

Jersey Water desalination plant boosts efficiency by 38%

Jersey Water desalination plant boosts efficiency by 38%UNITED KINGDOM: Jersey Water chose VLT® AQUA Drive from Danfoss when needing a major upgrade at its La Rosière desalination plant.

-

if (isSmallPicture) {

Danfoss drives prevent coastline flooding

Danfoss drives prevent coastline floodingNETHERLANDS: Efficient variable speed pump control using drives from Danfoss is the key to reliable flood prevention in Noordoostpolder municipality in the Netherlands.

-

if (isSmallPicture) {

Danfoss efficiencies help South African farmer to free up energy and achieve production goals

Danfoss efficiencies help South African farmer to free up energy and achieve production goalsSOUTH AFRICA: Discover how a South African farmer achieves 155,000+ kWh in annual energy savings thanks to a collaboration between Danfoss and BMG.