UNITED KINGDOM: For a recent major upgrade to its La Rosière desalination plant, Jersey Water chose VLT® AQUA Drive from Danfoss. With dedicated water-industry functionality, this drive provides outstanding harmonic performance and high efficiency.

The current desalination plant is the second on the La Rosière site, which is in the south-west corner of Jersey, the largest of the Channel Islands.

It was opened in 1999 as a replacement for an earlier distillation plant that had reached the end of its life.

The upgrade involved the installation of a large number of new pumps, almost all of which would need to be controlled by AC drives.

After investigating the available options and going through a competitive tendering process, Jersey Water decided that the VLT® AQUA Drive was the most suitable choice on both technical and commercial grounds. Accordingly, these drives were specified for all applications related to the upgrade project.

After the new plant had been in service for almost two decades, the ever-growing need for water on the island, due to population growth and climate change, led to the decision to undertake a major upgrade. This would increase the plant’s capacity from 6 Ml/day to 10.8 Ml/day, which is sufficient to meet around half of the island’s daily demand for water.

Active filter for absolutely minimal harmonics

Although the VLT® AQUA Drive offers excellent harmonic performance without the need for external filters, Jersey Water decided that, because minimal harmonic generation was such an important requirement for this project, it would still be desirable to install filters as a precautionary measure. Accordingly, Danfoss supplied active harmonic filters for use with the largest drives.

"We have been using AC variable speed drives from Danfoss for many years, and we have always been happy with their performance and reliability. One of the major requirements for this project, however, was that the drives should produce the lowest possible level of harmonics in the supply system. From my own experience I was confident that the Danfoss drives would meet this requirement – over the many years I’ve worked with them I have never had a problem with harmonics. In contrast, with drives from some other suppliers, distortion of the electrical supply has been evident by its effect on nearby instrumentation and computer equipment"

- Malcolm Berridge, Chief Engineer & Water Supply Manager for Jersey Water

Robust resistance in seaside environment

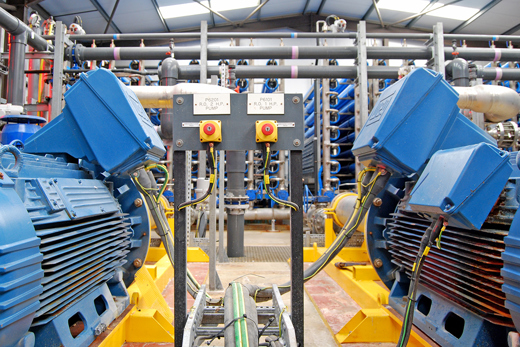

The largest of the new drives were required to control two high-pressure pumps with 600 kW motors operating at 690 V, which are fed from a custom 11 kV/690 V transformer. For these, 630 kW VLT® AQUA Drives were chosen.

Other drives for the project operate from 400 V supplies and include three with 160 kW ratings as well as nine with ratings between 55 kW and 18.5 kW. For all of these applications, VLT® AQUA Drive was used. In addition, Danfoss supplied two 110 kW energy-saving VLT® Soft Starter units for the seawater intake submersible pumps.

Because these drives and soft starters are used close to the sea, conformally coated printed circuit boards were specified to provide additional protection against corrosion. As part of the project, an existing motor control center was decommissioned and removed, and it was essential that the new drives should fit into the limited space this made available. The inherent compact construction of the VLT® AQUA Drive was an important benefit in achieving this and further space was saved by using IP54 versions of the drives which require no additional enclosure for protection.

“We are very happy with the Danfoss products as well as with the service and support the company has provided,” says Malcolm Berridge. “In particular, commissioning the new drives was fast and straightforward, thanks to the intuitive user interface and the dedicated pump functionality provided by the VLT® AQUA Drive series. The upgraded plant has now been in service for many months, and the drives have fully lived up to expectations in terms of performance and reliability. They are also making a big contribution to the enhanced energy efficiency of the plant, which has increased by between 36% and 38% since the upgrade.”

Related applications

-

if (isSmallPicture) {

Drives for mixers, dewatering and blowers

Drives for mixers, dewatering and blowersUse AC drives to control the speed of motors in a wide range of pump, blower, mixer and dewatering applications to help enhance performance and value while saving energy and costs in wastewater treatment.

-

if (isSmallPicture) {

Drives for water pumping

Drives for water pumpingFor water supply based on surface water or groundwater, Danfoss AC drives (or VFD pumps) can help optimize the production process whilst reducing energy and maintenance costs.

-

if (isSmallPicture) {

Water and wastewater monitoring

Water and wastewater monitoringIn water and wastewater applications, activating a condition monitoring system integrated into your VSDs optimizes the overall performance. Edge computing means there is no need to connect to the cloud.

Related case stories

Sarlux refinery saves energy with 12000 m3/day industrial desalination plant

Danfoss solutions enabled Acciona to create an innovative sea water reverse osmosis (SWRO) modular desalination plant for the Sarlux refinery in Sardinia, reducing energy consumption compared to traditional solutions.