NETHERLANDS: In 2019, the Zuiderzeeland District Water Board invested in new AC drives for three centrifugal pumps at the Buma pumping station in the town of Rutten. Danfoss partner ENGIE Electroproject was awarded the order to replace the drives and associated tasks. Since then, the Danfoss VACON® AC drives have prevented the Noordoostpolder municipality from flooding.

Flood prevention

Efficient variable speed pump control using drives from Danfoss is the key to reliable flood prevention.

Retrofit of installation from 2006

The pumping station is equipped with three large vertical centrifugal pumps, each with a maximum flow rate of 750 cubic meters per minute with a head of 5.6 meters. Each pump is driven by an 850 kW three-phase induction motor. The present pumps and the variable-speed 690 V motors have been in service since 2006. One of the AC drives began to suffer from an increasing number of malfunctions, while spare parts were difficult or even impossible to obtain. To ensure the ongoing availability of the pumps, the District Water Board decided in 2018 to replace the existing AC drives.

Danfoss and ENGIE Electroproject in partnership

Danfoss supports the system integrator ENGIE Electroproject with technical support and relevant inventory stocked locally. Sales Engineer Bas Verhoog from ENGIE Electroproject explains: “We design, execute and manage complete projects, and we handle upgrades along with any repairs to AC drives. We provide 24/7 service and have all required parts in stock. In an emergency, we can draw on the Danfoss stock in Gorinchem. Danfoss maintains an inventory of AC drives with a rated power of up to at least 1000 kW.”

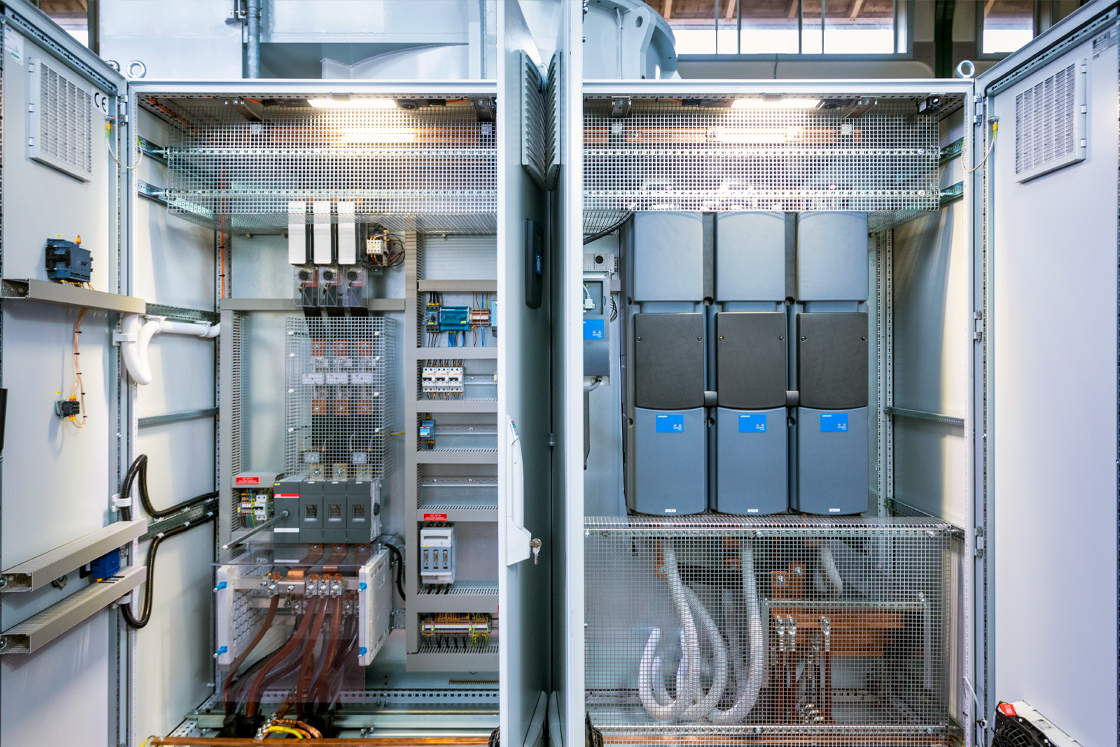

”For this project, we had to replace AC drives from a different brand. Our aim was to keep the existing cabling, including supply cables as well as signal and motor cables, as much as possible. We labeled and disconnected all existing connections, lifted the old panel out and installed the new one. We adapted the panels to the location, so we could connect all cables to the same points at the same height and screw them tight. That guarantees the highest reliability and is the least time-consuming option. Afterwards, all we had to do was adapt the water cooling.” - Bas Verhoog from ENGIE Electroproject

“Over the years Danfoss has supplied tens of thousands of AC drives – big and small – to the water sector. While the format installed in the Buma pumping station is less common, large numbers of small and medium-sized AC drives have been delivered for sewage pumping stations, aerators, stirrers in wastewater tanks, and so on. We know what matters and what the requirements are.” explains Danfoss Account Manager Ruud Versluis.

Quietness an advantage in populated areas

The AC drives and motors are cooled with water. The cooling water flows through a heat exchanger in a closed circuit. The heat exchanger is cooled by the discharge water from the pump, flowing via a second closed circuit. In both circuits the water is circulated using variable-speed pumps. Liquid cooling is quieter than air cooling, which is an advantage in populated areas, especially in the summer with higher ambient temperatures.

The 28-pole motors run at approximately 23 Hz, which corresponds to 98 rpm. They are started with no load. When the pressure in the pump reaches a specific level, the outlet valve is opened and the station starts to discharge water. Thanks to the speed control and the sturdy design of the pump and motor, the noise level is surprisingly low, even in full operation. It’s possible to conduct a normal conversation standing right next to the huge motor.

Buma pumping station

The Buma pumping station was instrumental in draining the Noordoostpolder in 1941–1942, along with the Smeenge pumping station on the east side of the polder. The Vissering pumping station near Urk was constructed later on. Today, the Buma pumping station is still essential to water level management in the polder.

Zuiderzeeland District Water Board

The Zuiderzeeland District Water Board is responsible for water management in the province of Flevoland and limited parts of Friesland and Overijssel. In this region, the water board looks after all dikes, waterways, pumping stations and water treatment plants to guarantee safety as well as an adequate supply of clean water. It has seven polder pumping stations (including three for the Noordoostpolder), five wastewater treatment plants, fifteen sewage pumping stations, and thousands of small dams, pumps, and everything else required to maintain the desired water level in Flevoland.