Since 2010, Marselisborg wastewater treatment plant has transformed its focus beyond minimizing energy consumed, to maximizing net energy surplus. Nowadays the facility has net production of both electricity and heat, supplying the district heating system in Denmark’s second-largest municipality, Aarhus. The carbon footprint has been reduced by 35 % accordingly.

Water and wastewater treatment facilities are normally the single largest electricity consumer for a municipality. Typically water and wastewater treatment processes account for 25 – 40 % of the municipal electricity consumption. The high consumption is related to the energy intensive processes but also its continuous operation cycle, 24/7 and 365 days annually.

Over the years focus has been on developing new processes and control strategies to reduce energy consumed per liter of water processed. However, at the same time the increasing demands upon wastewater treatment quality, for example in nutrient removal, in turn increase net energy consumption.

Energy balance optimization

Water and wastewater treatment processes are characterized by high load variation during the 24-hour cycle and seasonally throughout the year. The use of frequency converters has therefore steady increased in order to control blowers, pumps and other motorized equipment, to adapt to the changing demand.

Since 2010 Aarhus Water has worked intensively together with water environment consultants to improve the energy balance for Marselisborg wastewater treatment plant.

Learn about the latest features in our Aqua Drive

Our VLT® AQUA Drive is updated with the latest patented edge computing technology. Supporting high uptime for your facility and saving on operating costs, by supervising your motor and pumps. With the edge computing solution, data is collected several times per second, ensuring that any measurements outside the normal range trigger a warning, thus minimizing the risk of undetected abnormalities.

Key steps in the strategy

- Optimization of the nitrogen removal process using online sensor control. The frequency converter adapts the level of aeration precisely to the need. This control system reduces energy consumption and increases the amount of carbon left in the system.

- Blower technology upgrade to a high-speed turbo blower. The upgrade achieves further reduction of energy consumption in the aeration process.

- Aerobic sludge age control as a function of temperature and load on the plant. Here frequency converter control of the return sludge pumps is the key to achieving energy reduction and increased retained carbon in the system.

- Upgrade of combined heat and power (CHP) process for energy production, with 90 % energy efficiency.

These changes together with improvements including the effective co-production of electricity and heat based on methane gas extracted from the aerobic sludge digestion process have created the impressive results of:

- 130 % electricity production (30 % excess electricity)

- Excess heat production of about 2.5 GWh/year

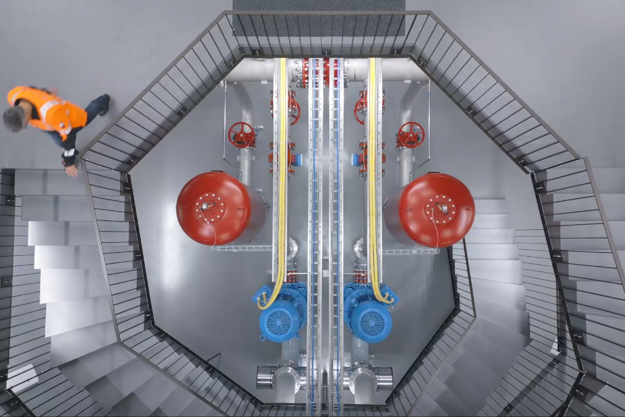

VLT® in every corner

Frequency converters are installed on almost all rotating equipment at Marselisborg WWTP: blowers, pumps, mixers and dewatering pumps. The frequency converters allow the plant to adapt to load variations, with maximum flexibility. Over 100 motors are controlled by VLT® frequency converters at Marselisborg.

Energy generation vision

The vision for Aarhus City is to extend energy generation even further, to achieve surplus production of energy from its wastewater treatment plants so high, that it can also meet the energy requirement of the city’s potable water supply. This will transform the single largest electricity consumer for the authority into an energy-neutral party.

Get more information

Related case stories

-

if (isSmallPicture) {

Hyrec relies on Danfoss for OARO brine mining in Indonesia

Hyrec relies on Danfoss for OARO brine mining in IndonesiaHyrec has pioneered a large-scale OARO brine mining plant that produces 220,000 tons of food-grade salt annually. By using Danfoss APP pumps and iSave ERDs for pre-concentration, the innovative solution optimizes energy efficiency, reduces costs, and ensures reliable operation in a remote location.

-

if (isSmallPicture) {

Salt Separation chooses Danfoss for cruise ship SWRO retrofit

Salt Separation chooses Danfoss for cruise ship SWRO retrofitSalt Separation Services boosted capacity by 75% and significantly reduced SEC by retrofitting a luxury cruise ship’s SWRO plant with a Danfoss APP pump and iSave ERD – all in the same tight space in the ship’s engine room.

-

if (isSmallPicture) {

APP pumps with ceramic chosen for containerized solutions

APP pumps with ceramic chosen for containerized solutionsWhen a Spanish engineering company needed one compact, reliable, and energy-efficient SWRO solution for three separate end users, Gefico’s engineers proposed a compact, modular train design that could be both containerized and built on skids. Danfoss’s ceramic APP pumps and iSave ERDs are at the heart of the seven trains that Gefico designed and produced

-

if (isSmallPicture) {

How a new water pumping station keeps supply flowing in Bern

How a new water pumping station keeps supply flowing in BernSWITZERLAND: The Wehrliau pumping station in Bern delivers up to 1.20 M liters of drinking water hourly. iC7 drives play a key role in ensuring reliable supply.

-

if (isSmallPicture) {

WatMan specifies Danfoss for the world’s largest cruise ship’s SWRO plant

WatMan specifies Danfoss for the world’s largest cruise ship’s SWRO plantWatMan Engineering chose Danfoss high-pressure pumps and ERDs for the SWRO plant supplying fresh water to the world’s largest cruise ship, Icon of the Seas. The Finnish specialist will also use Danfoss technology for the next two Icon-class ships.

-

if (isSmallPicture) {

Peter Taboada tailors energy-efficient wellboat SWRO with flexible Danfoss technology

Peter Taboada tailors energy-efficient wellboat SWRO with flexible Danfoss technologyPeter Taboada works closely together with wellboat builders to deliver efficient, space-saving water-making solutions that boost ROI. Flexible Danfoss high-pressure pumps and ERDs play a key role in the company’s success.