Higher overall efficiency

Our motor family allows top design flexibility – whether you are looking for high sophistication or simplicity itself.

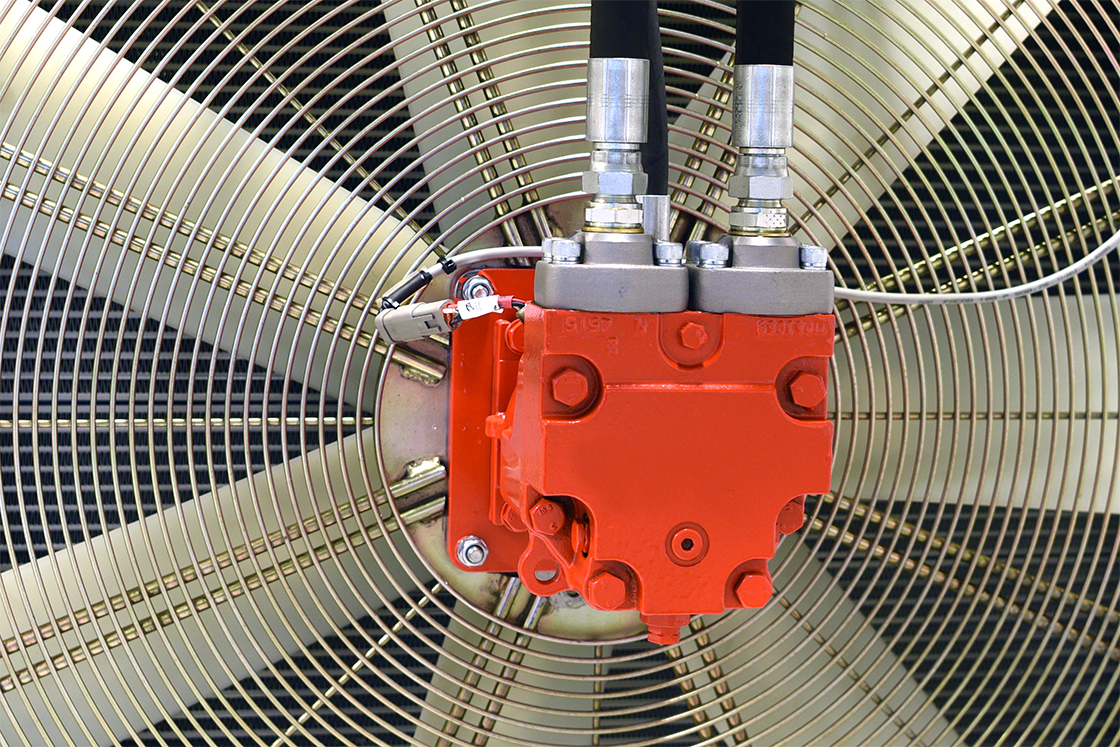

Our H1 bent axis motors are designed to complement the growing family of H1 axial piston pumps. Featuring proven 32 degree bent axis technology, zero degree capability and higher overall efficiency, they offer a number of significant advantages.

Features and benefits

High speed capability: The optimized surface finish combined with a high spring rate and best-in-class components. This ensures your machine has high speed capability at a minimal angle, allowing for maximum performance.

Shortest unit length on the market: The H1 Bent axis has the shortest unit lengths in its class.

Quality: Integrating solely IP67 and IP69K rated electric components and fulfilling the quality foal of 250 DPM. The H1 Bent axis motor convinces with superior quality.

Efficiency: The H1 Bent axis motor design leads to minimized control losses and enhanced efficiency. Due to inclusion of the smallest dead volume and flow optimized end cap as well as valve segment.

Robustness: One-piece housing and minimized case pressure ensure your machine operates with highest robustness. The strong synch joint improves dynamic torque capabilities.

Maximized pressure: Balanced 450 bar delta pressure enables you to operate your machines at high power, increasing your effectiveness.

Best serviceability: External shaft seal accessibility and built-in flexibility through the common design of the H1 family. This means easy and quick replacement and convertibility, simplifying machine operation for you.

Easy conversion: Each control supports all sizes of H1B motors to simplify motor conversion.

Excellent service: Choosing Danfoss as your partner, you will profit not only from excellent service through our trained experts. Also, you will profit from short delivery times – to provide you what you need, when you need it.

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| User guide | Counterbalance valve systems for H1B motors in open circuits technical information | English | Multiple | 01 Apr, 2024 | 3.9 MB | |

| Data sheet | H1 060 Bent Axis Variable Motor Data Sheet | German | Multiple | 09 Nov, 2023 | 1.2 MB | |

| Data sheet | H1 060 Bent Axis Variable Motor Data Sheet | French | Multiple | 14 Nov, 2023 | 1.5 MB | |

| Data sheet | H1 060 Bent Axis Variable Motor Data Sheet | English | Multiple | 06 May, 2023 | 1.5 MB | |

| Data sheet | H1 080 Bent Axis Variable Motor Data Sheet | French | Multiple | 14 Nov, 2023 | 1.5 MB | |

| Data sheet | H1 080 Bent Axis Variable Motor Data Sheet | English | Multiple | 30 May, 2023 | 1.5 MB | |

| Data sheet | H1 080 Bent Axis Variable Motor Data Sheet | German | Multiple | 09 Nov, 2023 | 1.2 MB | |

| Data sheet | H1 160 Bent Axis Variable Motor Data Sheet | English | Multiple | 16 Jun, 2023 | 871.4 KB | |

| Data sheet | H1 160 Bent Axis Variable Motor Data Sheet | French | Multiple | 14 Nov, 2023 | 875.2 KB | |

| Data sheet | H1 160 Bent Axis Variable Motor Data Sheet | German | Multiple | 09 Nov, 2023 | 1.1 MB | |

| Data sheet | H1 160cc Bent Axis Variable Motor with Counterbalance Valve DN32A Data Sheet | English | Multiple | 09 May, 2023 | 1.6 MB | |

| Data sheet | H1 210 Bent Axis Variable Motor Data Sheet | Italian | Multiple | 21 Jul, 2023 | 1.1 MB | |

| Data sheet | H1 210 Bent Axis Variable Motor Data Sheet | German | Multiple | 09 Nov, 2023 | 908.8 KB | |

| Data sheet | H1 210 Bent Axis Variable Motor Data Sheet | French | Multiple | 21 Jul, 2023 | 1.1 MB | |

| Data sheet | H1 210 Bent Axis Variable Motor Data Sheet | English | Multiple | 16 Jun, 2023 | 1.1 MB | |

| Data sheet | H1 210/250cc Bent Axis Variable Motor with Counterbalance Valve DN32B Data Sheet | English | Multiple | 09 May, 2023 | 1.8 MB | |

| Data sheet | H1 250 Bent Axis Variable Motor Data Sheet | German | Multiple | 09 Nov, 2023 | 1.7 MB | |

| Data sheet | H1 250 Bent Axis Variable Motor Data Sheet | Italian | Multiple | 14 Nov, 2023 | 2.1 MB | |

| Data sheet | H1 250 Bent Axis Variable Motor Data Sheet | French | Multiple | 14 Nov, 2023 | 2.1 MB | |

| Data sheet | H1 250 Bent Axis Variable Motor Data Sheet | English | Multiple | 08 Nov, 2023 | 2.1 MB | |

| User guide | H1B 060 080 100 160 210 250 Bent Axis Motors Technical Information | Japanese | Multiple | 10 Jun, 2025 | 11.4 MB | |

| User guide | H1B 060 080 110 160 210 250 bent axis motors technical information | English | Multiple | 25 Feb, 2025 | 9.8 MB | |

| User guide | H1B 060 080 110 160 210 250 bent axis motors technical information | Japanese | Japan | 10 Jun, 2025 | 12.5 MB | |

| User guide | H1B 060 080 110 160 210 250 Bent Axis Motors Technical Information | Chinese (CN) | China | 03 Jan, 2019 | 9.4 MB | |

| User guide | H1B 060 080 110 160 210 250 Bent Axis Motors Technical Information | German | Germany | 27 Nov, 2018 | 9.8 MB | |

| Data sheet | H1B 110 Bent Axis Variable Motor Data Sheet | French | Multiple | 14 Nov, 2023 | 1.4 MB | |

| Data sheet | H1B 110 Bent Axis Variable Motor Data Sheet | German | Multiple | 09 Nov, 2023 | 915.8 KB | |

| Data sheet | H1B 110 Bent Axis Variable Motor Data Sheet | English | Multiple | 16 Jun, 2023 | 1.4 MB | |

| User guide | Propel Application Library (PAL) Technical Information | English | Multiple | 07 Jun, 2019 | 3.7 MB | |

| Data sheet | Propel Application Library Data Sheet | English | Multiple | 11 Jun, 2019 | 441.6 KB | |

| User guide | Speed and Temperature Sensor Technical Information | English | Multiple | 14 Apr, 2025 | 2.6 MB |

Related products

-

if (isSmallPicture) {

Danfoss L/K medium-power variable axial piton motors

Danfoss L/K medium-power variable axial piton motorsDanfoss L/K medium-power variable axial piston motors feature clean design and small side for limited spaces. Displacement ranges from 25cc to 45cc, pressure ranges from 300 Bar to 400Bar.

Support

H1 B Motor Disassembly

Learn the steps to disassemble an H1 B Motor as part of a service event.

H1B Motor Assembly

Learn the steps to assemble an H1B Motor as part of a service event.

Related applications

-

if (isSmallPicture) {

Agriculture

AgricultureFarmers need agricultural machines that deliver the same high productivity every season. Hydraulic solutions from Danfoss ensure world-class performance from each machine, and a comfortable, stress-free working environment for their operators.

-

if (isSmallPicture) {

Construction

ConstructionSpace is limited on construction sites, and there are people working everywhere. Contractors need machines that can safely maneuver in a tight spot. At the same time they still need to be powerful enough to get the job done. At Danfoss, we deliver the components, software, and controls that enable your machines to run safely, efficiently and effectively.

-

if (isSmallPicture) {

Crane and material handling

Crane and material handlingCranes and other large handling machines are required to operate within very specific load ranges. Danfoss provides pressure transmitters that supply load limiting systems with crucial data, safeguarding your equipment, your load, and your operator.

-

if (isSmallPicture) {

Forestry

ForestryRough, sloping terrain and cramped working conditions call for robust and reliable forestry machines. We make sure you can manage everything from cutting trees and transport to preparing the forest floor for replanting. We have the smart hydraulic solutions your machines need for precise and efficient forestry operations.

-

if (isSmallPicture) {

Heavy machinery

Heavy machineryThink about the heaviest challenges in the open mining, road building and construction industry. Tasks such as cutting through rock or the Arctic permafrost; compacting thick layers of hot asphalt. As well as lifting huge, prefabricated wall panels into place.

-

if (isSmallPicture) {

Wheel loaders

Wheel loadersWork with us on new power solutions and experience wheel loader design in a new uplifted way.

Related solutions

-

if (isSmallPicture) {

Propel

PropelWe can partner with you to design and implement hydrostatic drive solutions. That provide operators with machines that are easier to maneuver. We are committed to helping you provide a more profitable investment for your customers.

-

if (isSmallPicture) {

Thermal management

Thermal managementDanfoss is here to help. With our complete fan drive solution, Danfoss is able to help you maximize available engine power. As well as, decrease fuel costs and increase operator productivity.

-

if (isSmallPicture) {

Total machine management

Total machine managementOur PLUS+1® platform delivers the software application development power you need — and doesn’t require specialized programming skills.

Case stories

-

if (isSmallPicture) {

All-wheel steering

All-wheel steeringAll-wheel steering is one example of how Danfoss is at the forefront of machine versatility. This helps customers getting the most out of their equipment. Electrohydraulic steering system enables operators to manually adjust the steering mode, allowing them to best match machine performance to the task at hand.

-

if (isSmallPicture) {

Autonomous solutions

Autonomous solutionsDanfoss Autonomy provides autonomous software, hardware and engineering services for the machines of tomorrow. Improving safety, precision and productivity, while helping OEMs speed up development and get machines to market faster. Accelerate your road to Autonomy.

-

if (isSmallPicture) {

Connectivity solutions

Connectivity solutionsPLUS+1® Connect combines telematics hardware, software infrastructure, a user-friendly interface and API integration on a single cloud platform to provide one cohesive, connected experience.

-

if (isSmallPicture) {

Fan drives

Fan drivesOptimize fan drive solutions with the Reverse Displacement Motor (RDM) and the new Series 45 Fan Drive Control (FDC). The RDM is a breakthrough in technological innovation and engineering.

-

if (isSmallPicture) {

Operator experience

Operator experienceWe are starting to focus on operator experience, helping to increase efficiency, productivity and well-being of the ones operating the mobile machines.

-

if (isSmallPicture) {

Propel

PropelWe can partner with you to design and implement hydrostatic drive solutions. That provide operators with machines that are easier to maneuver. We are committed to helping you provide a more profitable investment for your customers.

Visit PowerSource

In our digital catalog you can find product specifications, literature and helpful tools like product configurators, 2D/3D models, cross reference, crimp specs and many more.

Powersource

Visit PowerSource

In our digital catalog you can find product specifications, literature and helpful tools like product configurators, 2D/3D models, cross reference, crimp specs and many more.