Reduce development time

The Danfoss Propel Application Library (PAL) is a collection of function blocks for propel applications. Through the use of Danfoss PLUS+1® and PAL, you can develop complete propel systems for mobile machinery. Also, easily integrate any PAL function block into your existing propel system. This is regardless of the system configuration or hardware in use.

PAL provides you a competitive advantage by allowing for superior machine performance. It also can dramatically reduce your development time — getting you to market faster.

With PAL you can address many different challenges including hydrostatic core functionalities, fuel savings and anti-stall. As well as, engine overspeed, anti-braking control and more. Having proven, high-quality software blocks ready to drop into your existing system can reduce your development time by 50% or more. At the same time supporting the entire development process.

When choosing PAL, you're not simply receiving an industry-leading software solution, you're receiving the expertise and support only Danfoss can offer. Whether you want to collaborate with a Danfoss engineer on your unique challenge, or just want the peace of mind that you have the support you need, Danfoss is here for you.

Related products

-

if (isSmallPicture) {

Pro-FX® configure software

Pro-FX® configure softwarePro-FX® Configure software for fast and easy configuration of AxisPro hydraulic valves

-

if (isSmallPicture) {

PLUS+1® software

PLUS+1® softwarePLUS+1® GUIDE and Service Tool is the foundation of the PLUS+1® platform. It is engineered to accelerate your development process and bring higher quality machines to market faster.

-

if (isSmallPicture) {

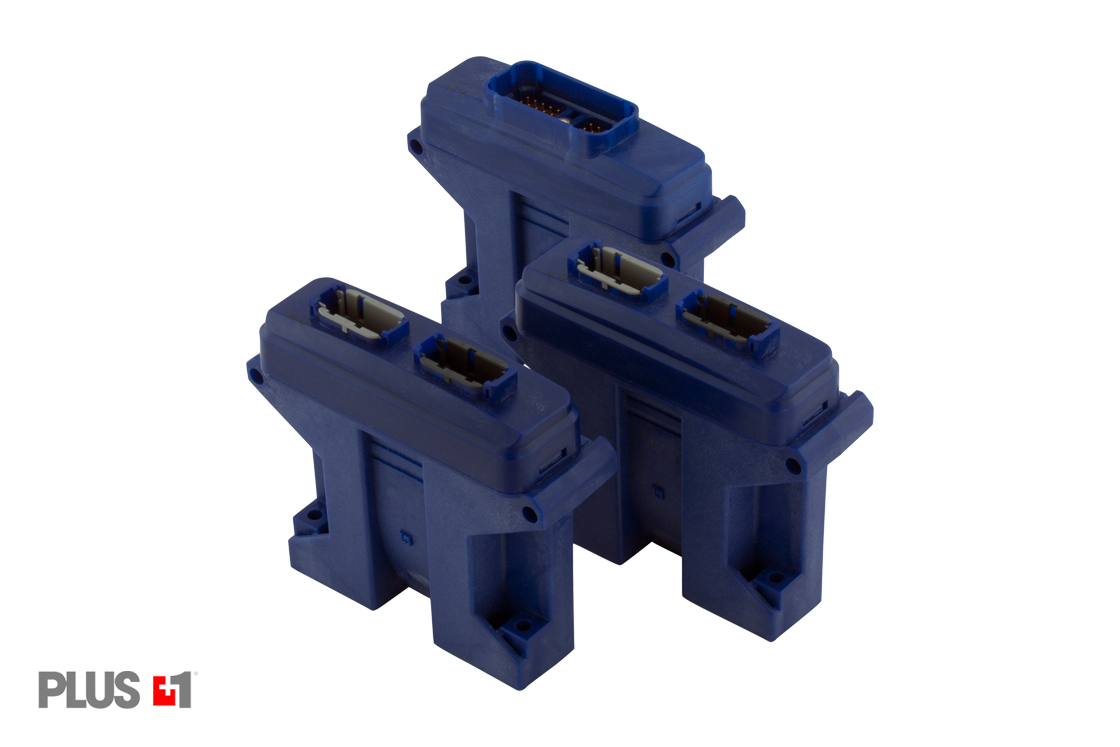

PLUS+1® SC microcontrollers

PLUS+1® SC microcontrollersOur PLUS+1® SC microcontrollers are flexible, powerful and functional safety compliant.

-

if (isSmallPicture) {

PLUS+1® high-current controllers

PLUS+1® high-current controllersOur PLUS+1® high current controllers, with their smart design and easy to program features, provide smooth control for high-current hydraulic applications.

-

if (isSmallPicture) {

PLUS+1® input/output modules

PLUS+1® input/output modulesOur CAN-based PLUS+1® input/output modules are stackable microcontroller add-ons providing smooth and effective hydraulic vehicle control functions.

Related solutions

-

if (isSmallPicture) {

Automotive control solutions

Automotive control solutionsAutomotive control technologies help increase machine controllability, regardless of operator skill level.

-

if (isSmallPicture) {

Best point control

Best point controlThis unique solution works by constantly adjusting operating parameters of key drivetrain components to maintain optimal efficiency points. These include the diesel engine, hydrostatic transmission, hydraulic pumps and motors.

-

if (isSmallPicture) {

Braking

BrakingHeavier vehicles. Smaller engines. Stricter stopping-distance regulations. They’re all challenges to heavy-equipment braking systems — and they’re all challenges that can be overcome with Danfoss solutions.

-

if (isSmallPicture) {

Dual Path

Dual PathToday’s machines get more done, more efficiently, thanks to advances in transmissions, pumps and motors. Danfoss is leading the way in perfecting the dual-path solutions that bring them all together. Delivering precision equipment control, less operator fatigue and greater productivity.

-

if (isSmallPicture) {

Total machine management

Total machine managementOur PLUS+1® platform delivers the software application development power you need — and doesn’t require specialized programming skills.

-

if (isSmallPicture) {

Traction control

Traction controlDanfoss has made advances in traction control an integral part of our mission to help engineer tomorrow.