Highly efficient and dependable solutions...

From temperature controls, evaporators, solutions for condensing units, or heating cables in floors and entrance doors, Danfoss has built a broad portfolio of products designed to deliver optimum protection of perishables, ensure efficient operation & extend the lifespan of your walk-in cooler / freezer system.

A cold room solution to meet every need

Found within the cold chain are cold storage facilities such as cold rooms. These facilities store or process both refrigerated and frozen products. They can be at the actual process facility or part of the distribution chain.

Compliance with hygiene and food safety regulations, but also energy regulations, is critical. Whether for a new installation or renovation, other parameters that must be considered when purchasing a cold room include ease of selection, refrigerant choice, installation options, reliability, maintenance, and operating costs.

Danfoss offers the widest portfolio of solutions for cold rooms to suit the diverse capacities, temperatures, and processes – for plug-in or remote installations, in small and larger sizes.

We offer contractor-friendly products & cold room solutions built with market leading expertise that are available everywhere and enable you to comply easily with regulations and save on installation and maintenance of walk-in refrigerators. Make the right choice for optimum protection of perishables, efficient operation and long lifespan.

Danfoss is a trustworthy partner for the cold room storage industry, with an extensive range of refrigeration monitoring solutions, experience and know-how. Our solutions for reliable walk-in cold rooms are specially developed to cover the extensive range of commercial refrigeration applications within; food service (restaurants, catering), specialty retail (butchers, bakeries etc.), process cooling (lab, medical, fruit ripening etc.), convenience stores, discount stores, and pharmacies.

Low GWP solutions

Our extensive low GWP portfolio for cold rooms is compatible with a broad spectrum of refrigerants — from A2L to CO2 and propane.

Find the cooling solution that matches your needs.

Features and benefits

Widest portfolio for all types of cold room and walk-in refrigeration applications

Reliable and highly energy efficient solutions

Long service life, low operation and maintenance costs

Compliance with refrigerant and energy regulations

Products suitable for use with lower GWP and natural refrigerants

Global and local application expertise

Simple product selection with Coolselector®2 software

Related products

-

if (isSmallPicture) {

Optyma™ Control

Optyma™ ControlOptyma™ Control is a cold room controller specifically designed for safety, protection, control, and ease of installation.

-

if (isSmallPicture) {

Electronic temperature control

Electronic temperature controlDanfoss offers a complete system for monitoring and optimizing any commercial refrigeration solution, such as for instance glass door merchandisers, air dryers, cold rooms, trucks and trailers.

-

if (isSmallPicture) {

Optyma™ Cooler

Optyma™ CoolerThe Optyma™ Cooler is an efficient unit cooler for walk-in coolers and freezers, designed for quick and easy installation. This compact unit uses cross-rifled heat exchanger tubing with a corrugated fin design and comes equipped with a maintenance-free, factory-balanced variable-speed EC fan motor to ensure high efficiency. Compliant with US DOE AWEF and NRCan standards and regulations.

-

if (isSmallPicture) {

Optyma™ Slim outdoor condensing unit

Optyma™ Slim outdoor condensing unitBuilt to reduce installation and maintenance costs, these smart designs and components save valuable time and money while making production even more efficient with the minimum impact on the neighborhood.

-

if (isSmallPicture) {

Compressors for refrigeration

Compressors for refrigerationEnergy efficient, sustainable, and smart refrigeration compressors for a varied range of commercial applications such as walk-in coolers and freezers, display windows, ice machines, glass door merchandisers, process cooling, and more. Most models are qualified for use with low GWP refrigerants, making them compliant with the majority of modern refrigerant regulations.

Learning

- eLesson: Walk-in coolers - Introduction

- eLesson: Walk-in coolers - Applications

- eLesson: Walk-in coolers - Cooling load calculation part 1

- eLesson: Walk-in coolers - Cooling load calculation part 2

- eLesson: Walk-in coolers - product selection part 1

- eLesson: Walk-in coolers - product selection part 2

Case studies

-

if (isSmallPicture) {

Danfoss adapts Optyma™ Slim condensing unit to meet G&D Chillers’ needs

Danfoss adapts Optyma™ Slim condensing unit to meet G&D Chillers’ needsDanfoss, to meet the needs of G&D Chillers, used the microchannel heat exchanger and DSH inverter scroll with intermediate discharge valve to customize the Optyma™ Slim condensing unit, making it compatible with the high-efficiency refrigerant R-410A.

-

if (isSmallPicture) {

Hot gas defrost - the next step in commercial kitchen refrigeration

Hot gas defrost - the next step in commercial kitchen refrigerationAs authorities and customers focus on energy efficiency standards and ratings to understand not just what a commercial refrigeration unit costs to buy, but what it costs to operate, the refrigeration design engineer needs to look again at the fundamentals and consider new approaches.

-

if (isSmallPicture) {

Walk-in coolers: a summary

Walk-in coolers: a summaryUse this list to learn what goes into making an efficient walk-in cooler or freezer.

-

if (isSmallPicture) {

Walk-in coolers: temperature controls

Walk-in coolers: temperature controlsThis is the sixth in our series of articles on walk-in coolers and freezers.

As seen throughout this article series, walk-ins are only as good as the components that are included in it. An important piece of the puzzle is the thermostat. A walk-in’s main job, not to put too fine a point on it, is to be cold. Maintaining the internal temperature is critical for meeting food safety standards and keeping product fresh for as long as possible. To do this, while also improving the energy efficiency of the system, a reliable thermostat is required.

-

if (isSmallPicture) {

Walk-in coolers: thermostatic expansion valves and solenoid valves

Walk-in coolers: thermostatic expansion valves and solenoid valvesThis is the fifth in our series of articles on walk-in coolers and freezers.

As with any refrigeration system, controlling the flow of refrigerant is vital in making a walk-in cooler or freezer operate properly. Two of the most common types of refrigerant control valves are thermostatic expansion valves and solenoid valves.

-

if (isSmallPicture) {

Walk-in coolers: pressure switches, ball valves, and fan speed controllers

Walk-in coolers: pressure switches, ball valves, and fan speed controllersThis is the fourth in our series of articles on walk-in coolers and freezers.

As seen in the previous articles in this series, each component of a walk-in cooler or freezer plays a vital role in ensuring optimal performance. In this article, we will examine how regulating small aspects of a walk-in’s refrigeration system, like fan speed, can have a major impact on performance.

News

-

if (isSmallPicture) {

Danfoss introduces the Optyma™ Cooler—a unit cooler for efficient walk-in coolers and freezersFriday, May 6, 2022

Danfoss introduces the Optyma™ Cooler—a unit cooler for efficient walk-in coolers and freezersFriday, May 6, 2022Designed for fast and easy installation, the Optyma™ Cooler is a compact and efficient unit cooler for walk-in cooler and freezer applications.

-

if (isSmallPicture) {

Introducing the new AK-RC 251 Optyma™ Control electronic temperature controllerThursday, January 28, 2021

Introducing the new AK-RC 251 Optyma™ Control electronic temperature controllerThursday, January 28, 2021Introducing the new Danfoss AK-RC 251 Optyma™ Control electronic controller, which eliminates the need for mechanical thermostats in cooling applications and defrost timers in freezer applications.

-

if (isSmallPicture) {

CO₂ made easy for small format stores: the Danfoss CO₂ MiniPack SolutionMonday, November 2, 2020

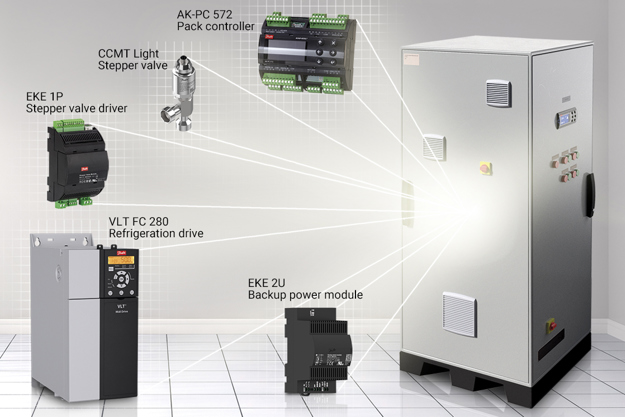

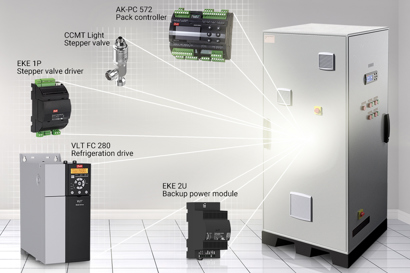

CO₂ made easy for small format stores: the Danfoss CO₂ MiniPack SolutionMonday, November 2, 2020The new CO2 MiniPack Solution makes it easy for the owners of small stores to harness the benefits of CO2 by combining five 100% compatible products into a single solution.

FAQ for cold rooms

General questions on low GWP refrigerants

Alternatives to R404A/R507 and R409A

Retrofit market for cold rooms

Impact on cooling performance

Technical characteristics of refrigerants

Flammable vs. non-flammable refrigerants

CO2 and propane refrigerants

Refrigerant transitions: What to be aware of?

General FAQ on cold rooms

Contact us

For further information, please contact us.