Faster customized controls

Series 45 offers a full line of displacements, controls, pressures and configurations that have been engineered to fit your multiple application needs. By utilizing proven, common components; the expertise of our system and applications engineers; and existing production sources for Series 45, Danfoss offers rapid prototyping and off -the-shelf solutions. These options allow you to reduce your time to market and provide a more competitive, reliable product to your customers.

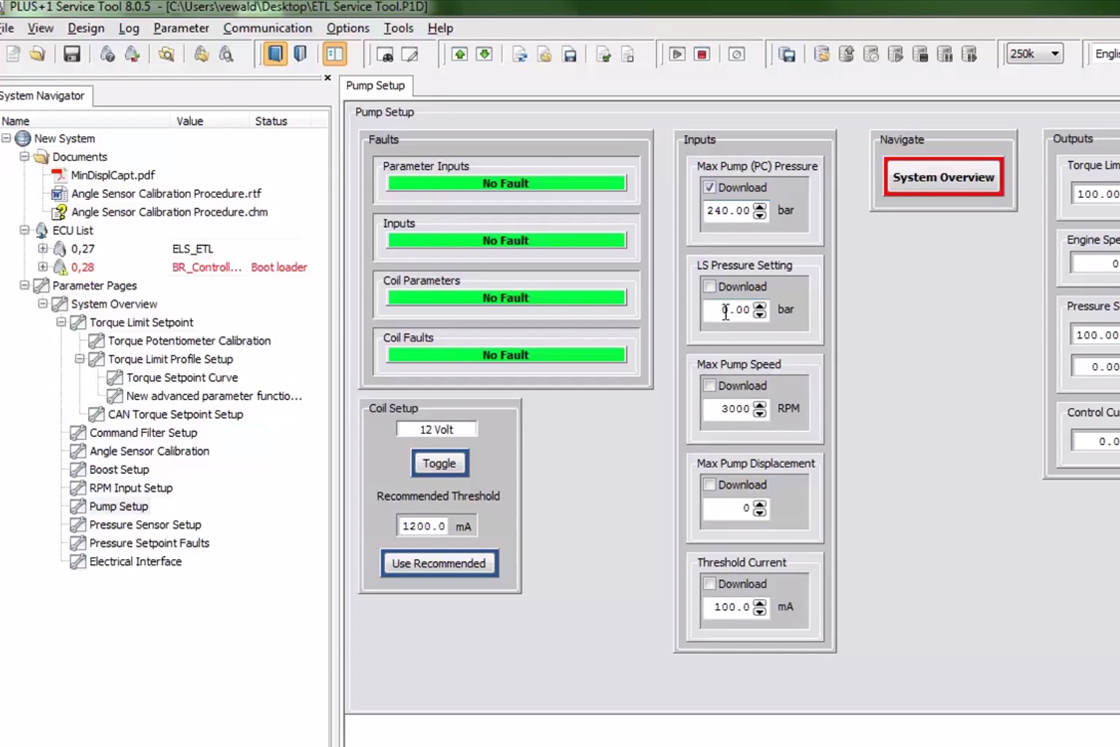

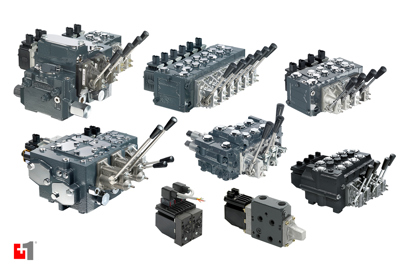

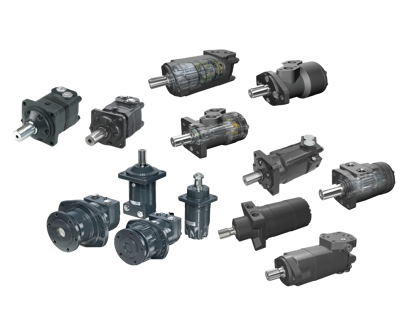

With the Danfoss PLUS+1® GUIDE programming environment and our Series 45 open circuit axial piston pumps, you can develop customized controls. This, faster than ever while reducing the cost and development time normally associated with programming. Ultimately resulting in faster time to market. PLUS+1 is the recommended way to higher performance, longer service life and lower costs. Our pumps are also designed to work seamlessly with PVG valves. Which provide electronic control, load-sensing and a flexible, modular design — assuring optimum performance.

Our K2 frame – the best combination of package size and weight on the market. With an optimized package, the K2 frame responds to customer needs. This, by significantly reducing pump weight and package size, while improving performance with increased rated pressure and higher-rated speed capabilities. The result is the best combination of package size and weight on the market.

The redesigned K2 offers numerous improvements

Reduced length up to 20% and reduced weight up to 10%

Overall weight reduction up to 30%

Greater efficiency with fan drive control

Improved overall sound level

Common Series 45 control options

Series 45 pumps are available in three additional frame sizes featuring a displacement range from 25-147cc.

Fan drive control (FDC)

Best in the industry for weight, package and serviceability. The lower minimum system pressures allowed by the fan drive control results in slower minimum fan speeds. This improves fan drive system efficiency and offers benefits for low cooling requirement conditions. An optimized design makes Danfoss fan drive control the best in the industry for weight, package and serviceability.

Electronic Torque Limiting (ETL) control

By using technology to maximize pressure within the available torque curve, the Danfoss ETL control delivers these proven benefits:

Increases productivity up to 22% over alternative torque controls

Moves up to 34% more material per gallon/liter of fuel

Increase fuel efficiency by up to 16%

ETL can reduce fuel consumption without any loss in productivity. The gains of running the engine at the lowest brake specific fuel consumption (BSFC) is offset by the increased flow of a larger pump. This can operate without the risk of stalling an engine — something traditional torque controls cannot match.

Electronic Displacement Control (EDC)

S45 K2 with EDC meets the diverse needs of your machine portfolio by offering the best combination of package size on the market, while allowing for simplification of your system.

The industry’s shortest EDC package length in a 45cc product.

Allows for infinite adjustment pump flow based on electronic control signal.

Proactively control flow without the need for flow control valves.

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Data sheet | Series 45 Axial Piston Open Circuit Pump ETL Control Data Sheet | English | Multiple | 31 Jan, 2019 | 1.7 MB | |

| User guide | Series 45 Axial Piston Open Circuit Pump Technical Information | German | Germany | 09 Mar, 2015 | 1.8 MB | |

| User guide | Series 45 Axial Piston Open Circuit Pump Technical Information | Japanese | Multiple | 12 Mar, 2024 | 12.9 MB | |

| User guide | Series 45 Axial Piston Open Circuit Pump Technical Information | English | Multiple | 06 Mar, 2024 | 14.0 MB | |

| User guide | Series 45 Axial Piston Open Circuit Pump Technical Information. | Chinese (CN) | Multiple | 21 Sep, 2023 | 14.3 MB | |

| Data sheet | Series 45 Axial Piston Open Circuit Pumps Data Sheet | English | Multiple | 09 Mar, 2015 | 1.5 MB | |

| Operating guide | Series 45 Axial Piston Pumps Electronic Torque Limiting Control User Manual | English | Multiple | 06 Mar, 2024 | 8.8 MB | |

| User guide | Series 45 Frame G Axial Piston Open Circuit Pump Technical Information Manual | English | Multiple | 09 Mar, 2015 | 1.3 MB | |

| User guide | Series 45 Frame H Axial Piston Open Circuit Pump Technical Information Manual | English | Multiple | 09 Mar, 2015 | 1.6 MB |

Related products

Related applications

-

if (isSmallPicture) {

Agriculture

AgricultureFarmers need agricultural machines that deliver the same high productivity every season. Hydraulic solutions from Danfoss ensure world-class performance from each machine, and a comfortable, stress-free working environment for their operators.

-

if (isSmallPicture) {

Construction

ConstructionSpace is limited on construction sites, and there are people working everywhere. Contractors need machines that can safely maneuver in a tight spot. At the same time they still need to be powerful enough to get the job done. At Danfoss, we deliver the components, software, and controls that enable your machines to run safely, efficiently and effectively.

-

if (isSmallPicture) {

Crane and material handling

Crane and material handlingCranes and other large handling machines are required to operate within very specific load ranges. Danfoss provides pressure transmitters that supply load limiting systems with crucial data, safeguarding your equipment, your load, and your operator.

-

if (isSmallPicture) {

Forestry

ForestryRough, sloping terrain and cramped working conditions call for robust and reliable forestry machines. We make sure you can manage everything from cutting trees and transport to preparing the forest floor for replanting. We have the smart hydraulic solutions your machines need for precise and efficient forestry operations.

-

if (isSmallPicture) {

Heavy machinery

Heavy machineryThink about the heaviest challenges in the open mining, road building and construction industry. Tasks such as cutting through rock or the Arctic permafrost; compacting thick layers of hot asphalt. As well as lifting huge, prefabricated wall panels into place.

-

if (isSmallPicture) {

Offshore oil and gas applications

Offshore oil and gas applicationsUpstream Offshore Oil and Gas activities are making up nearly 30% of global crude oil production. These are some of the harshest operating environments on the planet. Drilling in waters up to 3,000 meters deep requires equipment that is reliable and safe. this can help to maximize operating productivity and prevent unexpected downtime.

Related solutions

-

if (isSmallPicture) {

Steering

SteeringAs the global market leader in steering components and systems, Danfoss equips everything from small lawn machines to the largest dump trucks.

-

if (isSmallPicture) {

Total machine management

Total machine managementOur PLUS+1® platform delivers the software application development power you need — and doesn’t require specialized programming skills.

-

if (isSmallPicture) {

Work functions

Work functionsOur total systems approach integrates advanced Danfoss hardware and software to deliver exceptional work function control.

Case stories

-

if (isSmallPicture) {

Safe, efficient operation with maximum fuel economy

Safe, efficient operation with maximum fuel economyA Danfoss PLUS+1®-controlled drive solution ensures a safe, efficient operation with maximum fuel economy.