Danfoss ASV automatic balancing valves provide a simple, reliable and cost-effective way to create hydronic balance in two-pipe heating or cooling systems. They solve the technical issue of pressure fluctuations: the root cause of system imbalances and problems such as uneven heat distribution, noise and high energy consumption. ASV consists from two components; a return-pipe mounted differential pressure controller ASV-P or ASV-PV and flow-pipe mounted partner valve ASV-BD, ASV-I or ASV-M. An impulse tube connects both valves so the differential pressure over the riser can be controlled. In combination with Danfoss RA-N or RA-UN pre-setting valves on the radiators a perfectly balanced system, in both full and partial load conditions, is achieved.

The 4th generation of ASV-PV offers many unique product innovations. It is designed based on the needs from installers, designers and consultants with a focus on time saving during installation and commissioning of the system.

Features and benefits

Visible setting scale

Simple adjustment of the differential pressure setting, no special equipment is required. The clearly visible setting scale makes it easy to determine if the setting is adjusted correctly. The setting ring can be locked to prevent unauthorized adjustments.

Short build in height

The installation dimensions are decreased for flexible and convenient installation.

Faster and better flushing

Increase the reliability of the system by flushing it and remove before putting the system into operation. To flush and fill a system faster, the ASV-PV valve can temporarily be locked in an open position by a flushing ring accessory.

Integrated membrane

The valve body and pressure membrane are combined into one component. This design ensures optimal low flow performance and extremely ideal differential pressure sensitivity for each individual DN size valve.

Features and functionalities of Danfoss ASV-PV

A series of 5 animations describing the challenges, backgrounds and solutions for hydronic balancing of two-pipe heating systems in multi-family buildings.

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Application guide | Application guide | Italian | Italy | 07 Mar, 2021 | 10.1 MB | |

| Application guide | Application leaflet | Lithuanian | Lithuania | 18 May, 2021 | 19.0 MB | |

| Brochure | ASV automatic balancing valves Drive energy efficiency and increase customer satisfaction | German | Multiple | 28 Jan, 2022 | 2.2 MB | |

| Brochure | ASV automatic balancing valves Drive energy efficiency and increase customer satisfaction | Hungarian | Hungary | 23 Aug, 2017 | 1.1 MB | |

| Brochure | ASV automatic balancing valves Drive energy efficiency and increase customer satisfaction | English | Multiple | 27 May, 2016 | 333.6 KB | |

| Brochure | ASV automatic balancing valves Drive energy efficiency and increase customer satisfaction | Swedish | Sweden | 14 Apr, 2021 | 2.3 MB | |

| Brochure | ASV automatic balancing valves Smart heating optimization increases your building's lifetime value | English | Multiple | 27 May, 2016 | 706.1 KB | |

| Brochure | Energy saving solutions for renovation of heating and cooling systems | English | Multiple | 10 Sep, 2014 | 5.9 MB | |

| Brochure | Energy saving solutions for renovation of heating and cooling systems | Polish | Multiple | 19 Feb, 2019 | 5.9 MB | |

| Brochure | Energy saving solutions for renovation of heating and cooling systems | Romanian, Moldavian, Moldovan | Romania | 01 Sep, 2014 | 6.4 MB | |

| Brochure | Energy saving solutions for renovation of heating and cooling systems | Hungarian | Hungary | 01 Sep, 2014 | 6.4 MB | |

| Application guide | HVAC Application guide | Spanish, Castilian | Spain | 02 Feb, 2022 | 8.7 MB | |

| Application guide | HVAC Application guide | English | Multiple | 26 Oct, 2020 | 19.4 MB | |

| Application guide | HVAC Application guide | Polish | Poland | 14 Jun, 2021 | 11.3 MB | |

| Application guide | HVAC Application guide | Latvian | Latvia | 21 Apr, 2021 | 20.2 MB | |

| Application guide | HVAC Application guide | Czech | Czech Republic | 18 Nov, 2014 | 7.3 MB | |

| Application guide | HVAC Application guide 2021 | Hungarian | Hungary | 21 Sep, 2021 | 11.7 MB | |

| Brochure | Hydronic Balancing & Control product overview | English | United Kingdom | 11 Nov, 2014 | 7.1 MB | |

| Brochure | Hydronic Balancing & Control product overview | English | Multiple | 12 Dec, 2016 | 1.1 MB | |

| Brochure | Hydronic Balancing & Control product overview | German | Switzerland | 14 Oct, 2022 | 1.8 MB | |

| Brochure | Hydronic Balancing & Control product overview | Italian | Italy | 07 Mar, 2021 | 1.0 MB | |

| Brochure | Hydronic Balancing & Control product overview | German | Multiple | 30 Aug, 2022 | 1.6 MB | |

| Brochure | Hydronic Balancing & Control product overview | Czech | Czech Republic | 18 Nov, 2014 | 1.0 MB | |

| Brochure | Intelligente Heizungsoptimierung dient dem Werterhalt Ihrer Gebäude | German | Germany | 02 Oct, 2014 | 728.8 KB | |

| Brochure | Optimal 2 tool | English | Multiple | 17 Nov, 2016 | 2.5 MB | |

| Brochure | Optimal 2 tool | Danish | Multiple | 06 Apr, 2016 | 2.5 MB | |

| Brochure | Optimal 2 tool | Finnish | Multiple | 17 Mar, 2016 | 2.5 MB | |

| Application guide | Planner Manual Hydraulic | German | Multiple | 01 Apr, 2021 | 16.5 MB | |

| White paper | Practical guidelines for creating energy efficient multi-family residential heating systems | English | Multiple | 16 Oct, 2015 | 4.3 MB | |

| Brochure | Smart heating optimization increases your building's lifetime value | Swedish | Sweden | 24 Feb, 2015 | 723.3 KB | |

| Brochure | Two-pipe solutions: upgrade your two-pipe system with our Renovation+ Solution | German | Austria | 29 Aug, 2016 | 1.0 MB | |

| Brochure | Two-pipe solutions: upgrade your two-pipe system with our Renovation+ Solution | Dutch, Flemish | Netherlands | 16 Oct, 2014 | 646.5 KB | |

| Brochure | Two-pipe solutions: upgrade your two-pipe system with our Renovation+ Solution | Finnish | Finland | 15 Dec, 2016 | 1.0 MB | |

| Brochure | Two-pipe solutions: upgrade your two-pipe system with our Renovation+ Solution | Hungarian | Hungary | 22 Aug, 2017 | 1.5 MB | |

| Brochure | Two-pipe solutions: upgrade your two-pipe system with our Renovation+ Solution | German | Germany | 21 Feb, 2020 | 1.3 MB | |

| Brochure | Two-pipe solutions: upgrade your two-pipe system with our Renovation+ Solution | English | Multiple | 27 May, 2016 | 1.2 MB | |

| Brochure | Two-pipe solutions: upgrade your two-pipe system with our Renovation+ Solution | Estonian | Estonia | 14 Aug, 2017 | 1.1 MB | |

| Brochure | Two-pipe solutions: upgrade your two-pipe system with our Renovation+ Solution | German | Switzerland | 01 Mar, 2016 | 746.5 KB |

Software

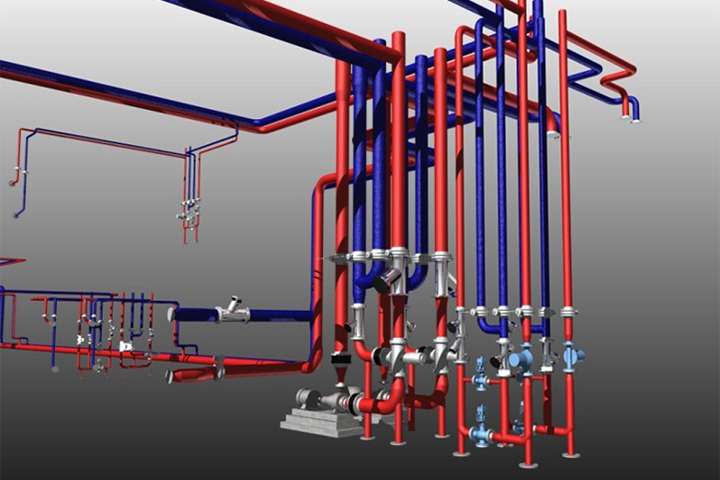

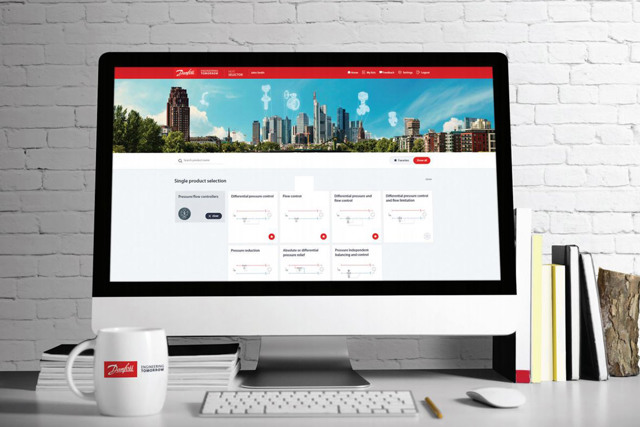

Danfoss SET 365 software

Our advanced Danfoss SET 365 3D design software will help you to design and calculate HVAC systems with Danfoss products. A 1-year subscription is FREE available for students, designers and other interested professionals.

Tools and apps

3D models and drawings

Case stories

-

if (isSmallPicture) {

Apartment block saves energy and money with AI and dynamic balancing

Apartment block saves energy and money with AI and dynamic balancingCentrally heated apartment buildings often suffer from variations in room temperatures due to inefficient and unbalanced heating systems. This can lead to unhappy residents complaining about lack of comfort or high energy bills. Swedish cooperative organization HSB aimed to use an intelligent monitoring and control solution to improve the energy efficiency and indoor comfort of a 12-apartment block that is connected to district heating.

-

if (isSmallPicture) {

New heating system with ASV automatic balancing valves in apartment building, Tallinn, Estonia

New heating system with ASV automatic balancing valves in apartment building, Tallinn, EstoniaToo warm, too cold, and no chance to regulate the heating inside the individual apartments—those were the issues facing the residents in a 9-storey apartment building in Tallinn, Estonia. By upgrading the existing one-pipe system into a two-pipe system with automatic hydronic balancing, the residents now enjoy improved comfort and 25 percent savings on the energy bill.

-

if (isSmallPicture) {

Hydronic balancing with ASV in residential building, Milan, Italy

Hydronic balancing with ASV in residential building, Milan, ItalySome years ago, the radiators in five 9-storey apartment buildings in Milan, Italy were equipped with thermostatic radiator valves. Not until the system was fitted with automatic balancing valves, however, did the benefits of the new TRVs materialize in terms of 14 percent energy savings, less noise from the heating system, and improved indoor comfort for the residents.

-

if (isSmallPicture) {

Hydronic balancing for a housing association, Mjolby, Sweden

Hydronic balancing for a housing association, Mjolby, SwedenEnergy efficiency and indoor comfort are top of mind among building owners today. In Sweden, the housing association Bostadsbolaget AB in Mjölby took action when they were confronted with a rising energy bill due to insufficient heat distribution in a 10-storey residential building.

-

if (isSmallPicture) {

ASV automatic balancing valves in buildings in 4 streets, Jonkoping, Sweden

ASV automatic balancing valves in buildings in 4 streets, Jonkoping, SwedenDuring the past few years a huge demand for sustainable living has emerged. The pressure on creating environmental friendly or green buildings is higher than ever. Also for existing buildings the need for not leaving a big blueprint on the globe is becoming increasingly important. In Jönköping, Sweden, the community living in the Västerkåkar neighborhood is going forward. In 2013 substantial changes to the communal heating system in the buildings in four streets showed that a green example can be set, in just a couple of steps.