Gain a competitive edge with Danfoss AC Drives

The fourth Industrial Revolution, or Industry 4.0, builds on the progress of automation by introducing elements of interconnectivity, data acquisition, machine learning and intelligent applications of analytics. AC drives play an important and powerful part in this transition by being the first point of interaction between sensors from the process, the motor in operation and communicating this information to a central control location.

Energy savings - Energy savings are tied to the technology and the fact that applications need less energy when idle or operating with partial loads. Danfoss drives do the trick.

Fully automated operation - Danfoss drives enable a facility to increase it’s automation capabilities. Not every application is the same across all industries, but with customized programming, customers can determine what parameters are essential to their specific needs.

100 % full load factory tested - Having received an order – a drive specified by the customer – our factory builds it and tests it against real motors before shipping.

Maximize up-time with Danfoss Drives

A breakthrough in drive technology: VLT® with Condition based monitoring

Danfoss VLT® Drives with built-in intelligence can now monitor the condition of motors and applications, allowing you to detect deviations in baseline parameters early in order to pro-actively intervene before the deviations have a negative impact on your operations

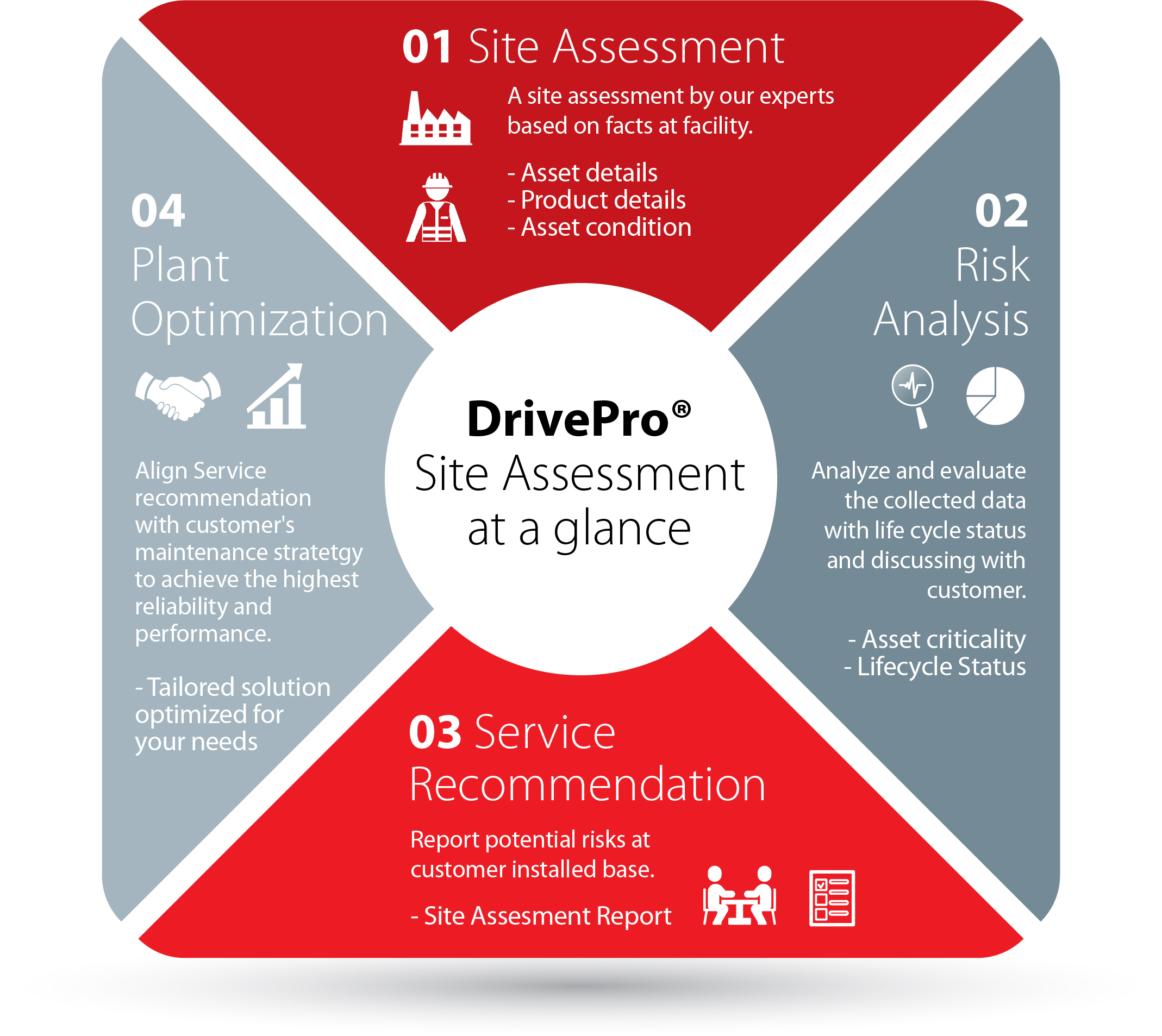

DrivePro® Site Assessments

With a DrivePro® Site Assessment, our well trained experts will assess your facility's VFD installed base and review your assets based on visual conditions, and evaluate the life-cycle stage of your individual assets. Based on this assessment you will receive a tailored service solution which will enable you to optimize up-time and reduce maintenance costs.

Site assessments may be done virtually using digital tools to support social distancing, or in person at your facility.

To support the efforts of essential businesses during the pandemic, Danfoss Drives is offering FREE DrivePro® Site Assessments to qualifying businesses.

See if you qualify for a FREE Assessment

Danfoss Drive applications

-

if (isSmallPicture) {

Drives for industrial compressors

Drives for industrial compressorsAchieve significantly lower energy consumption and lower operating costs, using Danfoss AC drives to continually adjust the compressor capacity to the actual heat load and process needs.

-

if (isSmallPicture) {

Drives for industrial crane and hoist movement

Drives for industrial crane and hoist movementTo optimize crane performance, Danfoss offers flexible control strategies combined with energy efficiency, operating within stringent safety requirements.

-

if (isSmallPicture) {

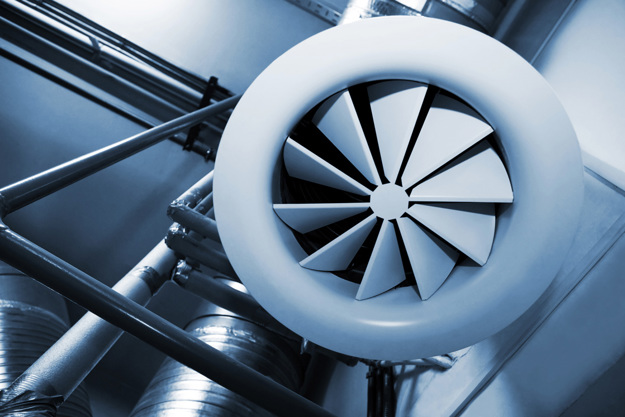

Drives for industrial fans

Drives for industrial fansWith Danfoss AC drives solutions for industrial ventilation you enjoy the benefits of high precision, user-friendly interfaces, distributed intelligence and low operating costs.

-

if (isSmallPicture) {

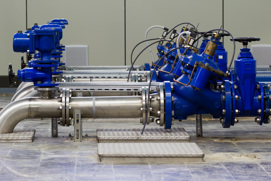

Drives for industrial pumps

Drives for industrial pumpsBy controlling industrial pumps with a Danfoss AC drive you can help optimize processes and significantly reduce energy and maintenance costs.

-

if (isSmallPicture) {

Drives for test stands

Drives for test standsBe a forerunner in emerging technologies evolving through electrification. Use Danfoss VFD's in your automotive and aerospace test stands; and go to market with proven products and solutions.

-

if (isSmallPicture) {

Drives for winding and unwinding in industry

Drives for winding and unwinding in industryFor lower energy consumption, increased performance, smooth ramping, and high reliability, use variable speed control for winders and unwinders.

Success stories

-

if (isSmallPicture) {

Addressing Dewatering Challenges at an Arizona Mine: VLT® AQUA Drive

Addressing Dewatering Challenges at an Arizona Mine: VLT® AQUA DriveWater presents a significant risk to mining operations, potentially causing equipment damage and environmental contamination. A robust pumping system is required to control the flow of water and remove it from the work site. A large copper mine in Arizona had reached a critical stage where they needed to replace their 250-horsepower (HP) dewatering pump and increase pumping capacity.

-

if (isSmallPicture) {

VACON® 1000 MV drives power deep pumping at Los Gatos mine

VACON® 1000 MV drives power deep pumping at Los Gatos mineMEXICO: Faced with the challenge of pumping stagnant water from depths of more than 400 meters, the Cerro Los Gatos mine opted for medium-voltage variable speed pump control using the VACON® 1000 drive from Danfoss. Drives were delivered and installed in the record time of 14 weeks from factory acceptance test.

-

if (isSmallPicture) {

Natel Energy decarbonizes electricity production through reliable hydropower systems with the help of VACON® AC Drives

Natel Energy decarbonizes electricity production through reliable hydropower systems with the help of VACON® AC DrivesNatel Energy brings state-of-the-art technology to the renewable energy market with an environmentally friendly and widely distributable hydropower generation system featuring an innovative new turbine design—Danfoss technology helps bring it to commercialization.

-

if (isSmallPicture) {

Hospital selects DrivePro® programs to keep costs down, maintain efficiency

Hospital selects DrivePro® programs to keep costs down, maintain efficiencyAs the largest regional medical center in San Joaquin County, St. Joseph’s Medical Center in Stockton, Calif., has 359-beds, employs over 400 physicians and more than 2,400 employees. Operating the HVAC mechanical equipment for a facility this large is a huge energy-conservation challenge. That's why St. Joseph’s made the decision to use variable frequency drives (VFDs) on HVAC pump and fan motors —a decision that continues to pay off today, thanks to an innovative upgrade plan using Danfoss VLT® Drives.

-

if (isSmallPicture) {

Cement Plant Realizes Solid Energy Savings with Variable Frequency Drives

Cement Plant Realizes Solid Energy Savings with Variable Frequency DrivesHolcim (US) engaged Danfoss for advanced variable frequency drive technology to assist in making its manufacturing site one of the most energy-efficient cement plants in the world.

-

if (isSmallPicture) {

33 kW/h energy savings at Alaskan mine

33 kW/h energy savings at Alaskan mineWhen a VACON® NXS drive was installed on a test fan in this Alaskan mine, the energy savings equated to 33 kW/h or annual savings of USD 100,000 for generator power.

Industrial drive products

-

if (isSmallPicture) {

VACON® 100 X

VACON® 100 XA drive for indoor and outdoor applications that withstands high pressure and vibration levels, water, heat and dirt.

-

if (isSmallPicture) {

VACON® 100 INDUSTRIAL

VACON® 100 INDUSTRIALDrive modules and enclosed drives that are easily integrated into all major control systems.

-

if (isSmallPicture) {

VACON® 20

VACON® 20Compact, but packed with programming functionality that’s ideal for OEM applications.

-

if (isSmallPicture) {

VACON® NXP Air Cooled

VACON® NXP Air CooledDesigned for a broad range of demanding applications, focusing on higher power sizes and system drives.

-

if (isSmallPicture) {

VACON® X5 HazLo

VACON® X5 HazLoVACON X5 HazLo is a first in the world of AC Drives. It has been certified for Class I; Division 2, Groups A, B, C, and D in a UL Type 4X enclosure.