Deliver quality they'll remember

Destemming is key to a wine's flavor and quality. Stalks and stems are detrimental to its taste. This is where the Danfoss VLT® Midi Drive FC 280 came to the rescue by optimizing management and control of the destemming machine's speed of rotation.

Read the Case Story

Balance productivity with environmental sustainability

-

Energy savings - Energy savings are tied to the technology and the fact that applications need less energy when idle or operating with partial loads. Danfoss drives do the trick.

-

Fully automated operation - Danfoss drives enable a facility to increase it’s automation capabilities. Not every application is the same across all industries, but with customized programming, customers can determine what parameters are essential to their specific needs.

-

100 % full load factory tested - Having received an order – a drive specified by the customer – our factory builds it and tests it against real motors before shipping.

Gain a competitive edge! Sign up below to receive updates from Danfoss, and as a thank you we will share with you a link to watch the webinar Increase productivity and improve efficiency using VFDs. The webinar covers:

- Learn why every motor needs a variable speed drive

- Understand how VFDs can reduce the number of spare parts

- How to remotely monitor your system using an AC Drive

- Gain a better understanding of condition-based monitoring and how to collect and analyze data for predictive maintenance.

Sign up to receive the recording

Maximize production up-time with Danfoss Drives

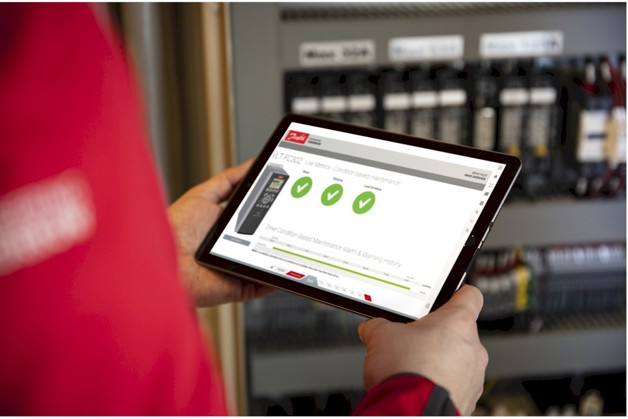

A breakthrough in drive technology: VLT® with Condition based monitoring

Danfoss VLT® Drives with built-in intelligence can now monitor the condition of motors and applications, allowing you to detect deviations in baseline parameters early in order to pro-actively intervene before the deviations have a negative impact on your operations

DrivePro® Site Assessments

With a DrivePro® Site Assessment, our well trained experts will assess your facility's VFD installed base and review your assets based on visual conditions, and evaluate the life-cycle stage of your individual assets. Based on this assessment you will receive a tailored service solution which will enable you to optimize up-time and reduce maintenance costs.

Site assessments may be done virtually using digital tools to support social distancing, or in person at your facility.

To support the efforts of essential businesses during the pandemic, Danfoss Drives is offering FREE DrivePro® Site Assessments to qualifying businesses.

See if you qualify for a FREE Assessment

VLT® Flex Concept - efficient drive solutions for challenging times

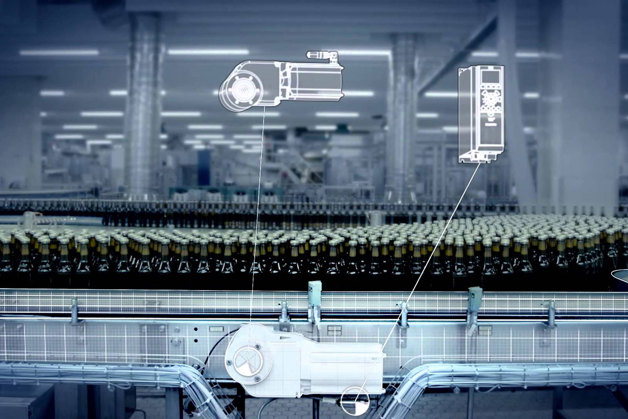

Modern manufacturing systems need higher efficiency, more flexibility and greater reliability in their drive systems than ever before — all necessary to reduce manufacturing costs. To meet that need, Danfoss has developed the VLT® FlexConcept® — a contemporary drive system using modern motor technology, combined with the most advanced variable frequency drives, and developed as a unified system.

- Highest efficiency

- Installation flexibility

- Reduced spare parts stock

- Hygienic options

Danfoss Drive applications

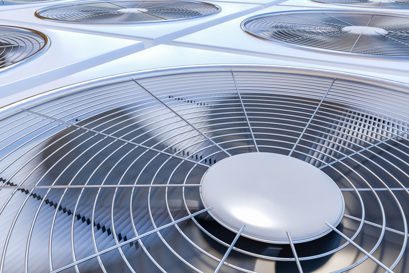

Compressor speed control provides constant pressure regulation as well as reducing your energy consumption, especially for part-load operation.

Ensure maximum uptime and lowest possible cost of ownership with hygienic, variable-speed conveyor control. EHEDG- and IPA-certified.

Variable speed fan control reduces costs by trimming energy consumption, and improves comfort levels by avoiding noise-generating frequencies.

Success stories

Challenged by aging machinery and no time for downtime, AB InBev Hoegaarden® chose Danfoss iC7-Automation and VLT® OneGearDrive®—for high energy efficiency.

Recipes for cheese are thousands of years old, passed down through generations and crossing continents —like the Swiss cheese recipes used by Shep Ysselstein, owner and “grand fromage” of Gunn’s Hill Cheese in Woodstock, Ontario, Canada.

Incorporating the VLT® FlexConcept® into a bottling-line expansion project helps save energy and minimize maintenance costs.

As the largest regional medical center in San Joaquin County, St. Joseph’s Medical Center in Stockton, Calif., has 359-beds, employs over 400 physicians and more than 2,400 employees. Operating the HVAC mechanical equipment for a facility this large is a huge energy-conservation challenge. That's why St. Joseph’s made the decision to use variable frequency drives (VFDs) on HVAC pump and fan motors —a decision that continues to pay off today, thanks to an innovative upgrade plan using Danfoss VLT® Drives.

Food processing plants require a dependable source of water in large quantities for the washing and rinsing, steaming, cooking, and cooling of food, and during plant sanitation operations. That’s why a large Midwest food processor wanted full control over its water supply by constructing a private water well on its own property. However, what looked like a simple solution was quite complex below the surface — as the well driller discovered when he embarked on the project.

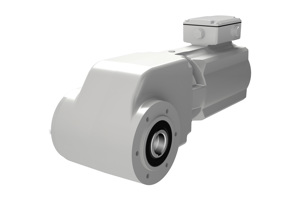

Industrial drive products

A highly efficient combination of a permanent magnet motor and optimized bevel gearing.

Thanks to its rugged design, the FCD302 drive can be mounted close to motors in demanding applications.

FC103 is dedicated to controlling compressors, pumps and fans for significant energy savings in refrigeration plants.