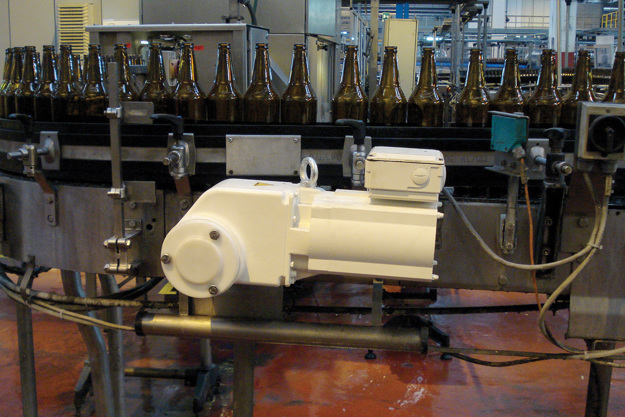

An energy-efficient drive system

The VLT® OneGearDrive® is a highly efficient, permanent magnet, three-phase synchronous motor coupled with an optimized bevel gear box which helps to optimize plant productivity and reduce energy costs.

With only one motor type and three available gear ratios, the motor concept covers all typical versions of conveyor drives commonly used in the food and beverage industry. The reduced range of physical configurations reduces costs and simplifies spare-part storage. Uniform mechanical dimensions reduce engineering and installation time and costs.

The drive comes in two versions: Standard for use in dry and wet production areas and Hygienic for use in wet areas and environments with high cleaning intensity including aseptic and cleanroom production areas.

Supply voltages and power range

- 3 x 380-480 V...0.75–2.2 kW

Features and benefits

Up to 40% energy savings compared to conventional systems thanks to high system efficiency

Less noise and no airborne germs and dirt particles drawn into motor and expelled back into the surrounding air due to fan-free operation

Unrestricted use and high protection in wash-down areas thanks to high degrees of protection

Easy to clean due to smooth enclosure design

Fast, reliable connection and lower installation costs as a result of motor and brake connections via terminal box with CageClamp® technology

Resistance to detergents and disinfectants thanks to aseptic coating

VLT® OneGearDrive® Literature

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Case story | Barilla | English | Multiple | 20 Mar, 2023 | 3.8 MB | |

| Case story | Birra Peroni | English | Multiple | 15 Mar, 2023 | 13.7 MB | |

| Case story | Borsodi Brewery | English | Multiple | 15 Mar, 2023 | 2.6 MB | |

| Case story | CocaCola Severna - Full case | English | Multiple | 08 Sep, 2022 | 4.2 MB | |

| Case story | CocaCola Severna - Mobile case | English | Multiple | 08 Sep, 2022 | 1.9 MB | |

| Case story | CocaCola Severna - Short case | English | Multiple | 08 Sep, 2022 | 2.2 MB | |

| Brochure | DrivePro® Services Overview | English | Multiple | 03 Feb, 2025 | 26.8 MB | |

| Brochure | DrivePro® Services Overview - US English | English | United States | 03 Feb, 2025 | 26.6 MB | |

| Case story | EFES Pilsen Turkey | English | Multiple | 15 Mar, 2023 | 1.8 MB | |

| Fact sheet | Fact Sheet - VLT® OneGearDrive® | English | United States | 31 Mar, 2023 | 379.3 KB | |

| Fact sheet | Fact Sheet - VLT® OneGearDrive® | English | Multiple | 31 Mar, 2023 | 366.5 KB | |

| Case story | Fairlife Michigan | English | Multiple | 15 Mar, 2023 | 2.8 MB | |

| Case story | Fairlife Michigan - US English | English | United States | 15 Mar, 2023 | 2.4 MB | |

| Brochure | FB Innovation Center | Gain competitive advantages from concentrated expertise and faster innovation cycles | English | Multiple | 29 Aug, 2023 | 7.2 MB | |

| Case story | FORST Brewery | English | Multiple | 19 Jul, 2023 | 1.6 MB | |

| Case story | Heineken Zagorka Brewery | English | Multiple | 16 Mar, 2023 | 3.1 MB | |

| Case story | Luxeapers | English | Multiple | 03 May, 2023 | 2.6 MB | |

| Case story | Nestle Waters | English | Multiple | 16 Mar, 2023 | 4.7 MB | |

| Case story | Riunite | English | Multiple | 17 Mar, 2023 | 2.6 MB | |

| Case story | Rothaus Brewery | English | Multiple | 19 Jul, 2023 | 3.2 MB | |

| Case story | Sibeg Bottling | English | Multiple | 19 Jul, 2023 | 1.5 MB | |

| Case story | Stiegl Brewery | English | Multiple | 17 Mar, 2023 | 3.1 MB | |

| Case story | Tavina | English | Multiple | 21 Mar, 2023 | 5.2 MB | |

| Brochure | Ten things you need to know about Ecodesign | English | Multiple | 27 Feb, 2023 | 574.9 KB | |

| Case story | Valser Mineral Water | English | Multiple | 19 Jul, 2023 | 2.1 MB | |

| Brochure | VLT® FlexConcept® | English | Multiple | 22 Nov, 2021 | 12.7 MB | |

| Operating guide | VLT® OneGearDrive OGD | English | Multiple | 15 Dec, 2021 | 4.0 MB | |

| Fact sheet | VLT® OneGearDrive® - ExtensionBoxTM | English | English | Multiple | 25 Jul, 2023 | 416.2 KB | |

| Brochure | VLT® OneGearDrive® Selection Guide | English | Multiple | 12 Nov, 2021 | 9.3 MB | |

| Brochure | VLT® OneGearDrive® Selection Guide | US English | English | United States | 12 Nov, 2021 | 9.3 MB | |

| Case story | Wieselburger Brewery | English | Multiple | 19 Jul, 2023 | 1.9 MB | |

| Case story | Wieselburger Brewery MEXICO | English | Multiple | 19 Jul, 2023 | 1.9 MB |

3D models and drawings

| Type | Name | Language | Updated | Download | File type |

|---|---|---|---|---|---|

| Dimensional drawing | OGD-H 1.25inch | 25 Jan, 2025 | 3.8 MB | .stp | |

| Dimensional drawing | OGD-H 1.25inch | 26 Jan, 2025 | 115.0 KB | ||

| Dimensional drawing | OGD-H 1.25inch | 26 Jan, 2025 | 1.0 MB | .dxf | |

| Dimensional drawing | OGD-H 1.4375inch | 27 Jan, 2025 | 3.8 MB | .stp | |

| Dimensional drawing | OGD-H 1.4375inch | 25 Jan, 2025 | 1.0 MB | .dxf | |

| Dimensional drawing | OGD-H 1.4375inch | 25 Jan, 2025 | 115.4 KB | ||

| Dimensional drawing | OGD-H 1.5inch | 26 Jan, 2025 | 1.0 MB | .dxf | |

| Dimensional drawing | OGD-H 1.5inch | 27 Jan, 2025 | 3.8 MB | .stp | |

| Dimensional drawing | OGD-H 1.5inch | 26 Jan, 2025 | 115.4 KB | ||

| Dimensional drawing | OGD-H 30mm | 26 Jan, 2025 | 3.8 MB | .stp | |

| Dimensional drawing | OGD-H 30mm | 26 Jan, 2025 | 114.7 KB | ||

| Dimensional drawing | OGD-H 30mm | 26 Jan, 2025 | 1.0 MB | .dxf | |

| Dimensional drawing | OGD-H 35mm | 25 Jan, 2025 | 114.7 KB | ||

| Dimensional drawing | OGD-H 35mm | 26 Jan, 2025 | 3.8 MB | .stp | |

| Dimensional drawing | OGD-H 35mm | 26 Jan, 2025 | 1.0 MB | .dxf | |

| Dimensional drawing | OGD-H 40mm | 25 Jan, 2025 | 114.4 KB | ||

| Dimensional drawing | OGD-H 40mm | 26 Jan, 2025 | 1.0 MB | .dxf | |

| Dimensional drawing | OGD-H 40mm | 26 Jan, 2025 | 3.8 MB | .stp | |

| Dimensional drawing | OGD-S 1.25inch | 26 Jan, 2025 | 1.2 MB | .dxf | |

| Dimensional drawing | OGD-S 1.25inch | 25 Jan, 2025 | 128.5 KB | ||

| Dimensional drawing | OGD-S 1.25inch | 25 Jan, 2025 | 4.5 MB | .stp | |

| Dimensional drawing | OGD-S 1.25inch with brake | 25 Jan, 2025 | 1.2 MB | .dxf | |

| Dimensional drawing | OGD-S 1.25inch with brake | 25 Jan, 2025 | 4.5 MB | .stp | |

| Dimensional drawing | OGD-S 1.25inch with brake | 27 Jan, 2025 | 129.2 KB | ||

| Dimensional drawing | OGD-S 1.4375inch | 25 Jan, 2025 | 127.7 KB | ||

| Dimensional drawing | OGD-S 1.4375inch | 26 Jan, 2025 | 1.2 MB | .dxf | |

| Dimensional drawing | OGD-S 1.4375inch | 27 Jan, 2025 | 4.5 MB | .stp | |

| Dimensional drawing | OGD-S 1.4375inch with brake | 26 Jan, 2025 | 129.4 KB | ||

| Dimensional drawing | OGD-S 1.4375inch with brake | 25 Jan, 2025 | 4.5 MB | .stp | |

| Dimensional drawing | OGD-S 1.4375inch with brake | 25 Jan, 2025 | 1.2 MB | .dxf | |

| Dimensional drawing | OGD-S 1.5inch | 26 Jan, 2025 | 128.7 KB | ||

| Dimensional drawing | OGD-S 1.5inch | 26 Jan, 2025 | 1.2 MB | .dxf | |

| Dimensional drawing | OGD-S 1.5inch | 25 Jan, 2025 | 4.5 MB | .stp | |

| Dimensional drawing | OGD-S 1.5inch with brake | 25 Jan, 2025 | 129.2 KB | ||

| Dimensional drawing | OGD-S 1.5inch with brake | 26 Jan, 2025 | 1.2 MB | .dxf | |

| Dimensional drawing | OGD-S 1.5inch with brake | 27 Jan, 2025 | 4.5 MB | .stp | |

| Dimensional drawing | OGD-S 30mm | 26 Jan, 2025 | 1.2 MB | .dxf | |

| Dimensional drawing | OGD-S 30mm | 26 Jan, 2025 | 129.0 KB | ||

| Dimensional drawing | OGD-S 30mm | 26 Jan, 2025 | 4.5 MB | .stp | |

| Dimensional drawing | OGD-S 30mm with brake | 25 Jan, 2025 | 128.7 KB | ||

| Dimensional drawing | OGD-S 30mm with brake | 25 Jan, 2025 | 4.5 MB | .stp | |

| Dimensional drawing | OGD-S 30mm with brake | 26 Jan, 2025 | 1.2 MB | .dxf | |

| Dimensional drawing | OGD-S 40mm | 26 Jan, 2025 | 128.0 KB | ||

| Dimensional drawing | OGD-S 40mm | 26 Jan, 2025 | 4.5 MB | .stp | |

| Dimensional drawing | OGD-S 40mm | 26 Jan, 2025 | 1.2 MB | .dxf | |

| Dimensional drawing | OGD-S 40mm with brake | 26 Jan, 2025 | 4.5 MB | .stp | |

| Dimensional drawing | OGD-S 40mm with brake | 26 Jan, 2025 | 128.6 KB | ||

| Dimensional drawing | OGD-S 40mm with brake | 27 Jan, 2025 | 1.2 MB | .dxf | |

| Dimensional drawing | torque arm set_178g5006 | 26 Jan, 2025 | 69.2 KB | .stp | |

| Dimensional drawing | torque arm set_178g5006 | 26 Jan, 2025 | 276.7 KB | .dxf | |

| Dimensional drawing | torque arm set_178g5919 | 26 Jan, 2025 | 703.1 KB | ||

| Dimensional drawing | torque arm set_178g5919 | 26 Jan, 2025 | 185.0 KB | .stp | |

| Dimensional drawing | torque arm set_178g5919 | 26 Jan, 2025 | 82.4 KB | .dxf |

Approvals

| Type | Software Characteristic | Name | Version | Language | Released | Status | Download | File type |

|---|---|---|---|---|---|---|---|---|

| Danfoss EU-UK 00730262 A6 | English | 1.3 MB |

Related applications

Conveyors.

-

if (isSmallPicture) {

Drives for conveyors in food and beverage applications

Drives for conveyors in food and beverage applicationsEnsure maximum uptime and lowest possible cost of ownership with hygienic, variable-speed conveyor control. EHEDG- and IPA-certified.

Case studies

-

if (isSmallPicture) {

Future-proof energy efficiency at AB InBev Hoegaarden® brewery

Future-proof energy efficiency at AB InBev Hoegaarden® breweryChallenged by aging machinery and no time for downtime, AB InBev Hoegaarden® chose Danfoss iC7-Automation and VLT® OneGearDrive®—for high energy efficiency.

-

if (isSmallPicture) {

Cantine Riunite saves 30% energy

Cantine Riunite saves 30% energyIncorporating the VLT® FlexConcept® into a bottling-line expansion project helps save energy and minimize maintenance costs.

-

if (isSmallPicture) {

Bottling is more competitive when it is sensorless

Bottling is more competitive when it is sensorlessTo achieve higher productivity and energy efficiency on two new bottling lines, Tavina chose the Danfoss VLT® FlexConcept drive system.

-

if (isSmallPicture) {

Peroni wins >30% in conveyor efficiency

Peroni wins >30% in conveyor efficiencyPeroni Brewery wins at least 30% better conveyor belt efficiency in a bottling line upgrade with VLT® FlexConcept®.

-

if (isSmallPicture) {

Traditional brewery engineers tomorrow

Traditional brewery engineers tomorrowSince upgrading its filling plant to energy-efficient drives from Danfoss, Stiegl Brewery of Salzburg saves about EUR 15,000 annually in maintenance and energy consumption.

-

if (isSmallPicture) {

Nestlé Waters reduces spare-part inventory by up to 70 %

Nestlé Waters reduces spare-part inventory by up to 70 %Nestlé Waters chose the VLT® FlexConcept® to help fulfill their goal to optimize environmental sustainability and minimize energy consumption.