Improve part-load compressor efficiency

Danfoss drives optimize the control of compressors to reduce energy consumption and provide constant pressure regulation. Speed control is advantageous when an air compressor is running for long periods at part-load. And fewer starts and stops reduce mechanical wear.

For instance, compressor-driven chillers are reliant on the energy-saving features of drives to efficiently dissipate as much heat as possible. Hygiene requirements demand drives with robust enclosures that resist daily high-pressure washdowns. Danfoss has a number of VLT® drives of varying sizes with IP66/UL Type 4X protection that will fulfill this need.

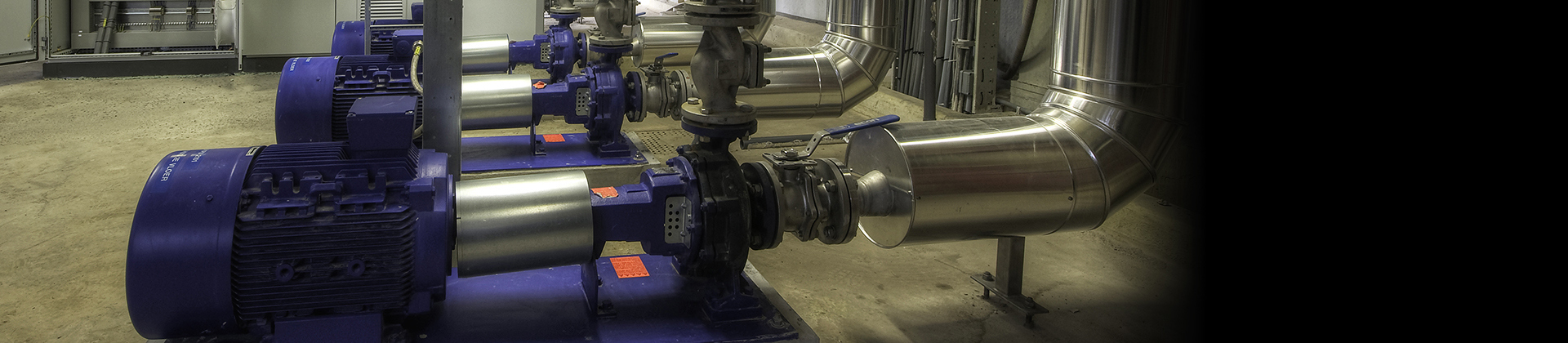

Cascade configuration enables optimal interaction between compressor and drive under partial load. The base load is handled by a single compressor controlled by a VLT® Refrigeration Drive. When consumption rises, the drive starts up additional compressors one at a time. As a result, the compressors work largely at their optimum efficiency point, and the drive constantly maintains maximum energy efficiency throughout the system. The same principle also applies to drive-controlled fans and pumps.

Boiler-house Renovation at Unilever Saves 25% Energy with VLT® AQUA Drive

In 2009, Unilever’s research on the efficiency of the existing boiler-house showed that a 25% reduction in CO2 emissions could be achieved by taking an innovative approach to renovate the boiler-house.

Products

-

if (isSmallPicture) {

VLT® Refrigeration Drive FC 103

VLT® Refrigeration Drive FC 103FC103 is dedicated to controlling compressors, pumps and fans for significant energy savings in refrigeration plants.

-

if (isSmallPicture) {

VLT® AutomationDrive FC 301 / FC 302

VLT® AutomationDrive FC 301 / FC 302The VLT® AutomationDrive FC301 / FC302 is designed for variable speed control of all asynchronous motors and permanent magnet motors. It comes in a standard version (FC301) and an advanced high dynamic version (FC302) with additional functionalities.

Case studies

-

if (isSmallPicture) {

85% startup energy reduction for Reindl Kältetechnik

85% startup energy reduction for Reindl KältetechnikVLT® Refrigeration Drive provides optimal control of the dehumidifier in the hay drying process.

-

if (isSmallPicture) {

Unilever saves 25% energy

Unilever saves 25% energyVLT® AQUA Drive FC 202 maximizes pump efficiency and optimizes energy savings as part of boiler-house renovation project.