The NovoCon® digital IoT actuators are tailor made to fit Danfoss AB-QM Pressure Independent balancing and Control Valves. They establish the perfect connection between superior hydronic HVAC system performance and smart building automation solutions.

Traditional controlled actuators, at best, offer an analog feedback signal to the BMS controller. Instead, the NovoCon® actuators offer many digital system parameters directly to the Building Management System via BACnet or Modbus. It for example exchanges accurate information about the actuator/valve position, settings, temperatures, alarms etc.

- Digital Hydroncis size M: View the 3D model

- Digital Hydroncis size S: View the 3D model

All the information provides System Integrators and technical facility managers a unique insight in, and remote access to, the HVAC system. The actual HVAC data can be used to optimize the systems performance, improving the indoor comfort and achieve an energy efficient building.

NovoCon® is an essential device in the transition to HVAC 4.0 for smart, connected buildings. The actuators enable continuous monitoring, active energy management and preventive maintenance at the highest comfort level and lowest operating costs. The digital actuators can be used in many building types such as offices, hotels and hospitals. But also in cruise ships, universities, data centers, shopping malls, museums or supermarkets.

NovoCon® series digital IoT actuators

Danfoss NovoCon® series of digital actuators for PICVs consists of four versions;

- NovoCon® S fits AB-QM valves DN 10-32 and new AB-QM 4.0 valves DN 15-32. These combinations are applicable for various types of Terminal Units such as Fan Coil Units (FCU), chilled beams and radiant panels. The valves are used in two-pipe heating or cooling and four-pipe heating/cooling change-over systems for flows from 20-4,000 l/h.

- For fast and reliable installation the NovoCon® S can only be connected to the BMS and wired in daisy-chain by using our series of plug & play connection cables

- NovoCon® M fits dedicated AB-QM NovoCon® valves DN 40-100. These combinations are applicable for the control of higher volume flows from 3-59 m3/h in e.g. Air Handling Units (AHU).

- NovoCon® L fits AB-QM valves DN 125-150. These combinations are applicable for the control of high volume flows from 36-190 m3/h in e.g. chiller applications.

- NovoCon® XL fits AB-QM valves DN 200-250. These combinations are applicable for the control of the highest volume flows from 80-370 m3/h in e.g. District cooling applications.

Built-in I/O

The digital actuators also offers built-in I/O's for added functionality, flexibility and cost savings. In some applications this can replace I/O modules from the BMS. A few examples of using the actuators’ I/O’s are:

- Flow & energy indication by connecting sensors for return and supply temperature measurement with NovoCon® Energy

- Optimized solution for 4-pipe change-over applications with NovoCon® CO6 (only for NovoCon® S)

- To connect different sensors (e.g. room temperature, humidity, or condensation) and control different devices such as fans with NovoCon® Remote I/O cable.

Are you looking for solutions that contribute in reducing your buildings' carbon footprint?

Then have a look at our animation video about Danfoss Digital Hydronics.

Remote commissioning of AB-QM 4.0 PICV with NovoCon S digital actuator

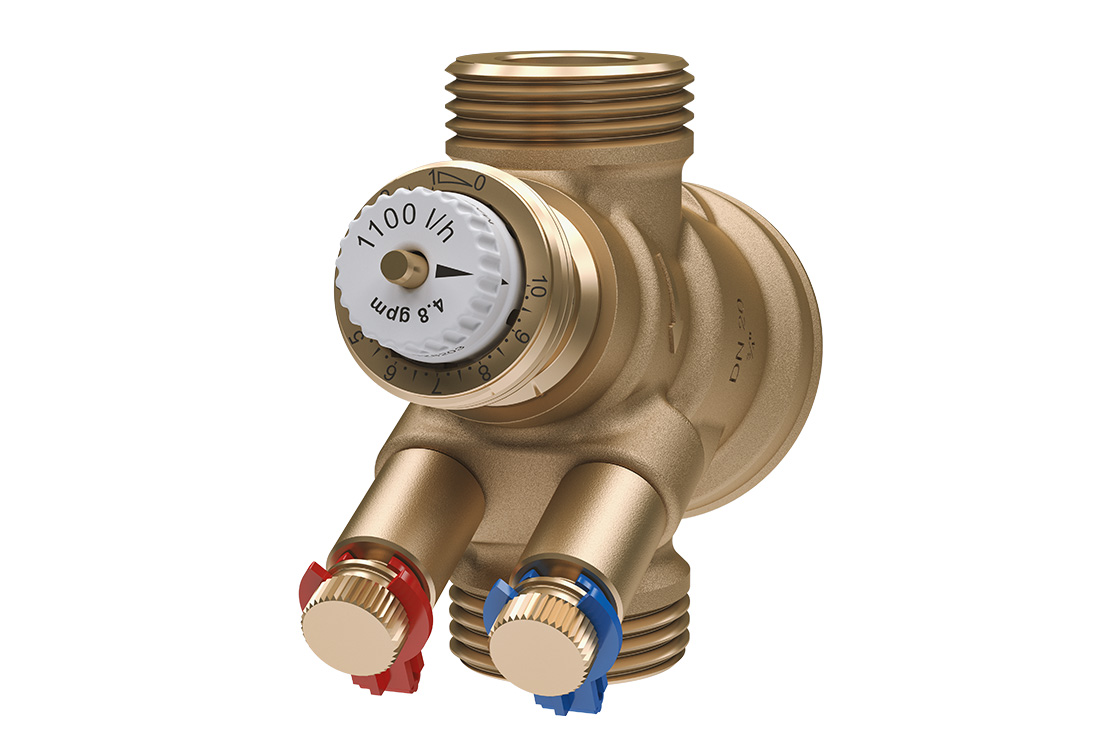

The animation shows an AB-QM 4.0 valve in a working HVAC system at maximum design flow of 1100 l/h. The valve absorbs pressure fluctuations and maintains the design flow.

With the NovoCon S digital actuator the design flow is remotely re-commissioned to a design flow of 40%, about 440 l/h as shown on the display of the energy/flow meter.

Danfoss NovoCon S allows simultaneous, remote, commissioning of 64 valves at the same time.

HVAC heating and cooling with AB-QM 4.0, NovoCon S and ChangeOver 6

The animation shows a climate panel in an office environment, providing cooled air into the room. Once the demand changes for heating, the NovoCon S digital actuator steers the ChangeOver 6 actuator and corresponding valve. The 6-way valve closes off the supplied chilled water and opens the supply for heated water. The NovoCon S is used to adjust the design flow setting on the AB-QM 4.0 PICV remotely.

The optional set of temperature sensors can be applied to measure the actual supply- and return temperatures. The temperatures are provided to the BMS for monitoring or active energy management to optimize the energy efficiency.

Advantages of digital hydronic HVAC systems

Introducing HVAC 4.0 for smart buildings with AB-QM and NovoCon® digital IoT actuators

Features and benefits

Remote access

Via the BMS system and bus communication all actuators can be remotely accessed. This saves a lot of time during the installation and commissioning of the system as well as during the many years the building is operational.

Continuous commissioning

System data can be retrieved and analyzed in order to optimize the HVAC system. In case adaptions to e.g. setting of design flows are required, it can easy be done. On one, a few or all actuators at the same time. Continuously monitoring and commissioning the system saves time and costs throughout the life cycle of the building.

Predictive maintenance

Don't wait for HVAC components to fail, cause complaints and need for urgent and disturbing service activities. Instead you can see where and when an issue might occur and you can take precautions and act pro-actively.

Flexibility all over

The designers or system integrators of BMS systems can realize customized HVAC solutions for every project. In case the building user wants to refurbish the building, the HVAC system can be adapted accordingly without physical adjustments to the BMS components.

Smart HVAC control solution for the I-tower at WTC Amsterdam, the Netherlands

In 2017 World Trade Center (WTC) located in Amsterdam at the ‘Zuid-as’, renovated one of the nine buildings, the 7 stories high I-tower. A high-end HVAC system, LED lighting and other technical improvements established a smart and modern office environment. Danfoss AB-QM PICV valves and NovoCon® S digital actuators play an essential role.

Documents

Promotional and Technical Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Brochure | AB-QM Actuator Selection Infographic - UK | English | United Kingdom | 15 Jan, 2021 | 8.6 MB | |

| Brochure | eBook | Danfoss Digital Hydronics™ | English | Multiple | 15 Feb, 2022 | 5.5 MB | |

| Application guide | HVAC Application guide | English | Multiple | 26 Oct, 2020 | 19.4 MB | |

| Brochure | Infographic - Actuator selection for AB-QM PICVs | English | Multiple | 17 Sep, 2024 | 3.4 MB | |

| Brochure | NovoCon | Digital actuator for HVAC | English | Multiple | 20 Jun, 2017 | 772.5 KB | |

| Brochure | NovoCon series product leaflet | English | Multiple | 02 Dec, 2020 | 391.3 KB | |

| Data sheet | NovoCon® S, M, L and XL Digital actuators | English | United States | 12 Apr, 2022 | 9.7 MB | |

| Data sheet | NovoCon® S, M, L and XL Digital actuators | English | Multiple | 10 Feb, 2025 | 10.2 MB | |

| Fact sheet | NovoCon® S, M, L, XL and Flow sensor | English | Multiple | 14 Jan, 2025 | 5.7 MB | |

| White paper | Reconfiguring AHU control for better performance | English | Multiple | 12 Oct, 2022 | 2.0 MB |

Environmental Product Declaration (EPD) Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Product Environmental Information - BI | EPD ABQM 4.0 DN 15-32 & NovoconS | English | Multiple | 27 Jan, 2023 | 4.1 MB | |

| Product Environmental Information - BI | EPD ABQM DN 40 -100 with NovoCon M actuator | English | Multiple | 27 Nov, 2023 | 2.7 MB | |

| Product Environmental Information - BI | EPD ChangeOver6 Actuator and NovoCon ChangeOver6 Actuator | English | Multiple | 14 Nov, 2024 | 2.8 MB |

Software

Danfoss SET 365 software

Our advanced Danfoss SET 365 3D design software will help you to design and calculate HVAC systems with Danfoss products. A 1-year subscription is FREE available for students, designers and other interested professionals.

| Type | Software Characteristic | Name | Version | Language | Released | Status | Download | File type |

|---|---|---|---|---|---|---|---|---|

| Application software | Firmware | Firmware for NovoCon® L/XL | v. 1.42 | English | 28 Nov, 2024 | Released | 315.0 KB | .zip |

| Application software | Firmware | Firmware for NovoCon® M | V1.42 | English | 22 Jul, 2024 | Released | 309.2 KB | .zip |

| Application software | Firmware | Firmware for NovoCon® S | 5.44 | English | 02 Dec, 2024 | Released | 451.9 KB | .zip |

| Application software | Configuration file | Software for NovoCon® configuration tool | V2.3.0.12 | English | 04 Mar, 2024 | Released | 50.3 MB | .zip |

Related products

-

if (isSmallPicture) {

AB-QM 4.0 Pressure Independent Control Valves (PICV) DN15 - DN32

AB-QM 4.0 Pressure Independent Control Valves (PICV) DN15 - DN32AB-QM 4.0 Pressure Independent Control Valves (PICVs) are the successor of Danfoss AB-QM. They offer best-in-class specifications and easy installation. The scaling- and clogging resistant design secures and outstanding reliability and long lifetime. The required design flow can easily be established by turning the setting wheel on top of the valve to a presetting between 10-100% of the nominal flow. A wide variety of on/off, modulating and digital actuators is available to accurately control the flow through the valves.

-

if (isSmallPicture) {

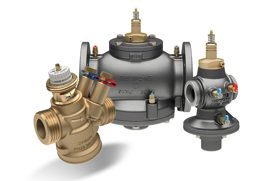

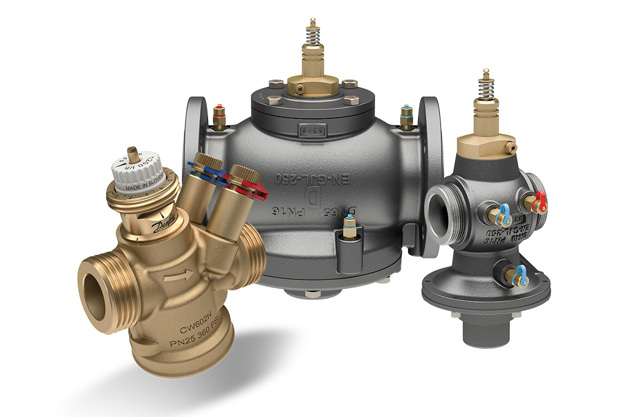

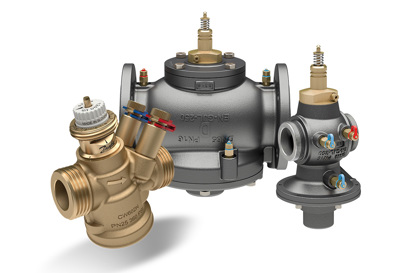

AB-QM Pressure Independent Control Valves (PICV) DN15 - DN250

AB-QM Pressure Independent Control Valves (PICV) DN15 - DN250AB-QM Pressure Independent balancing and Control Valves (PICV) provide both a control functionality and dynamic balancing solution for HVAC heating and cooling systems. PICVs are designed for various types of terminal units, Air Handling Units (AHU), chillers and provide high indoor comfort and energy efficiency in public and commercial buildings.

BIM library for MEP designs

Get your 3D BIM objects and start design HVAC 4.0 for smart buildings.

Case stories

Building: Office

Application: Hydronic balancing and remote control of 4-pipe heating/cooling change-over system.

Challenge: Gaining BREEAM credits for energy monitoring and ensure fast, fail free installation.

Solution: Digital NovoCon S actuator combined with AB-QM 4.0 PICVs and ChangeOver6 Energy. The combination balances the system hydronically, allow remote access via a BMS and provides actual energy consumption data per climate panel during both heating and cooling operation.

Building: Office

Application: Hydronic balancing and remote control of 4-pipe heating/cooling change-over system

Challenge: Ensure a flexible to use HVAC system with DGNB sustainability certification

Solution: Digital NovoCon actuator combined with AB-QM control valves and NovoCon CO6 combined with ChangeOver6 as a combination balance the system hydronically, allow remote access via a BMS and control the room temperatures during both heating and cooling operation.

Building: Office

Application: Climate panels with a four-pipe change-over system for Heating and Cooling

Challenge: Establish a modern, innovative HVAC control system optimized for flexibility in (changing) usage of office space

Solution: Integration of Danfoss field devices with the Building Management System via BACnet bus-communication

Katowice Business Centre is a modern office building where Danfoss hydronic balancing solutions are used; AB-QM balancing and control valves in combination with revolutionary NovoCon® actuators.

In the city of Rotterdam, the Netherlands, a new education and rehabilitation center called ROeR (ROtterdam education and Rehabilitation center) is being built. Terberg Totaal installatie, responsible for the HVAC systems, choose Danfoss NovoCon® Energy for it’s pluggable daisy-chain cabling to minimize cable lengths. In addition the integrated I/O functionality of NovoCon® provided added value.

Videos

Tender texts

Modulating, high accuracy, geared actuator with field bus (BACnet MS/TP and Modbus RTU) connectivity used to control pressure independent balancing and control valves type AB-QM DN10-32.

Control signal digital: BACnet MS/TP, Modbus RTU

Control signal analog: 0-10V/2-10V, 0-20mA/4-20mA

Direct connection to 6-port ball valve actuator with position feedback signal (*1)

Direct connection to 2x PT1000 surface/immersed sensors and emission power indication (*2)

Direct connection I/O: 2x resistance, AO and AI (*3)

Actuator functionality is remotely accessible via the field bus:

- Design flow pre-setting

- Flushing the valve and terminal unit

- Error during closing intrinsic alarm reporting

- Alarm if CO6 6-port ball valve actuator is blocked, in manual override or disconnected (*1)

- Supply and return temperature readings, emission power indication (*2)

- Energy counter (kWh, MJ, kBTU) (*2)

- Alarm high/low deltaT and temperature sensors disconnected (*2)

- Alpha characteristics setting

- Speed selection 3/6/12/24 s/mm

- Opening/closing time selection from 18s to 700s

- Auto MAC addressing (BACnet only)

- Auto Baud rate detection

- Flow indication based on measured stroke in l/h

Eu.bac interchangeability approved in combination with PIBCV valve

Supply Voltage: 24V DC/AC 50/60Hz

Spindle position accuracy: ±0.05mm

Cables: Halogen free plug-in available in 1.5m, 5m and 10m length

Temperature sensors: plug-in 2x PT1000 surface or immersed 1.5m length

64 actuators can be connected to the same network

Supports BACnet service Change of Value (COV)

Supports remote Firmware updates

IP Class: 54

Stroke: 7mm

BACnet Testing Laboratories (BTL) listed BACnet MS/TP fieldbus device

Manual override function

Configuration tool available easy configuration, commissioning and firmware updates

Commissioning tool available for addressing, parametrization and hydronic continuous commission

Pulse input for Flow sensor to present real flow over the bus.

Warnings via field bus for: No flow and flow out of expectation

Full range from DN15-250.

(*1) CO6 application

(*2) Energy application

(*3) Remote I/O application

Modulating, high accuracy, geared actuator with bus connectivity used to control pressure independent control valves type AB-QM NovoCon® DN 40-100.

Control signal digital: BACnet MS/TP, Modbus RTU

Control signal analog: 0-10V/2-10V, 0-20mA/4-20mA

Actuator functionality is remotely accessible via the fieldbus:

- design flow pre-setting

- flushing the valve and terminal unit

- error during closing/opening/calibration alarm

- LIN/LOG/α-setting characteristics setting

- selectable speed

- opening/closing time selection

- auto MAC addressing (BACnet)

- auto Parity detection (Modbus)

- auto Baud rate detection

- Flow and energy indication

Supply Voltage 24V ac/dc

64 actuators can be connected to the same network

IP Class: 54

Stroke: 20mm

Manual override function

Click on mounting

LED status indication

BACnet Testing Laboratories (BTL) listed BACnet MS/TP fieldbus device

Pulse input for Flow sensor to present real flow over the bus.

Warnings via field bus for: No flow and flow out of expectation

Full range from DN15-250.

Modulating, high accuracy, geared actuator with bus connectivity used to control pressure independent control valves type AB-QM DN125-150.

Control signal digital: BACnet MS/TP, Modbus RTU.

Control signal analog: 0-10V/2-10V, 0-20mA/4-20mA

Actuator functionality is remotely accessible via the fieldbus:

- design flow pre-setting

- flushing the valve and terminal unit

- error during closing/opening/calibration alarm

- LIN/LOG/α-setting characteristics setting

- selectable speed

- opening/closing time selection

- auto MAC addressing (BACnet)

- auto Parity detection (Modbus)

- auto Baud rate detection

- Flow and energy indication

- Safety function in NovoCon® L SU/SD. Spring up or spring down for AB-QM DN125-150 valves.

Supply Voltage 24V ac/dc

64 actuators can be connected to the same network

IP Class: 54

Stroke: 50 mm

Manual override function

LED status indication

Pulse input for Flow sensor to present real flow over the bus.

Warnings via field bus for: No flow and flow out of expectation

Full range from DN15-250.

Modulating, high accuracy, geared actuator with bus connectivity used to control pressure independent control valves type AB-QM DN200-250.

Control signal digital: BACnet MS/TP, Modbus RTU.

Control signal analog: 0-10V/2-10V, 0-20mA/4-20mA

Actuator functionality is remotely accessible via the fieldbus:

- design flow pre-setting

- flushing the valve and terminal unit

- error during closing/opening/calibration alarm

- LIN/LOG/α-setting characteristics setting

- selectable speed

- opening/closing time selection

- auto MAC addressing (BACnet)

- auto Parity detection (Modbus)

- auto Baud rate detection

- Flow and energy indication

Supply Voltage 24V ac/dc

64 actuators can be connected to the same network

IP Class: 54

Stroke: 50 mm

Manual override function

LED status indication

Pulse input for Flow sensor to present real flow over the bus.

Warnings via field bus for: No flow and flow out of expectation

Full range from DN15-250.