Danfoss BOCK® Compressors: Your solution for environmentally friendly cooling

Compressors for mobile applications

Danfoss BOCK® mobile aluminum compressors are at the forefront of eco-friendly climate control. They play a vital role in creating a comfortable atmosphere in buses, trains, and transport cooling.

Today's air conditioning systems prioritize passenger comfort, energy efficiency, and environmental compatibility, focusing on emission-free heat pumps for vehicle heating.

Our compressors excel in these areas, being lightweight and robust, enhancing overall system efficiency. They offer features like efficient thermal management, the use of eco-friendly refrigerants (CO2 and low-GWP), and reliability.

Product range - Mobile applications:

-

if (isSmallPicture) {

StarCO₂mpressors for electric buses and trains

StarCO₂mpressors for electric buses and trainsIntroducing Danfoss BOCK®'s CO2 StarCO2mpressors HR40 and HR60, revolutionizing electric bus and train air conditioning. Experience space-saving, eco-friendly cooling with proven reliability and robust construction. Achieve sustainability, innovation, and extended vehicle range for a greener future.

-

if (isSmallPicture) {

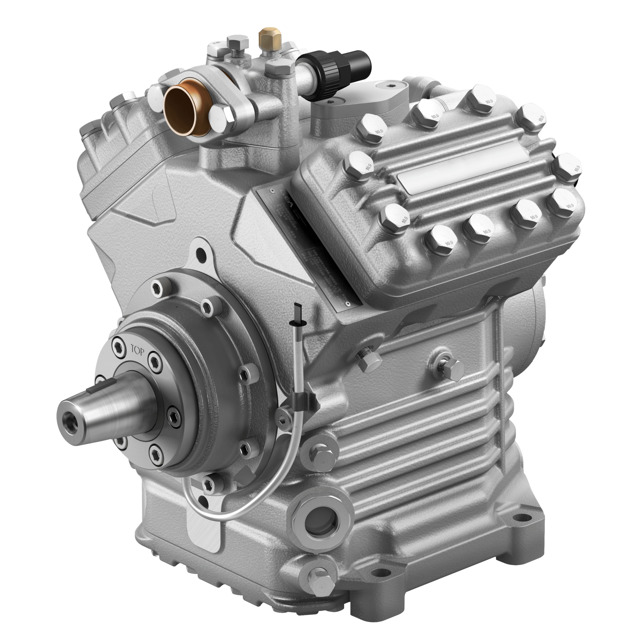

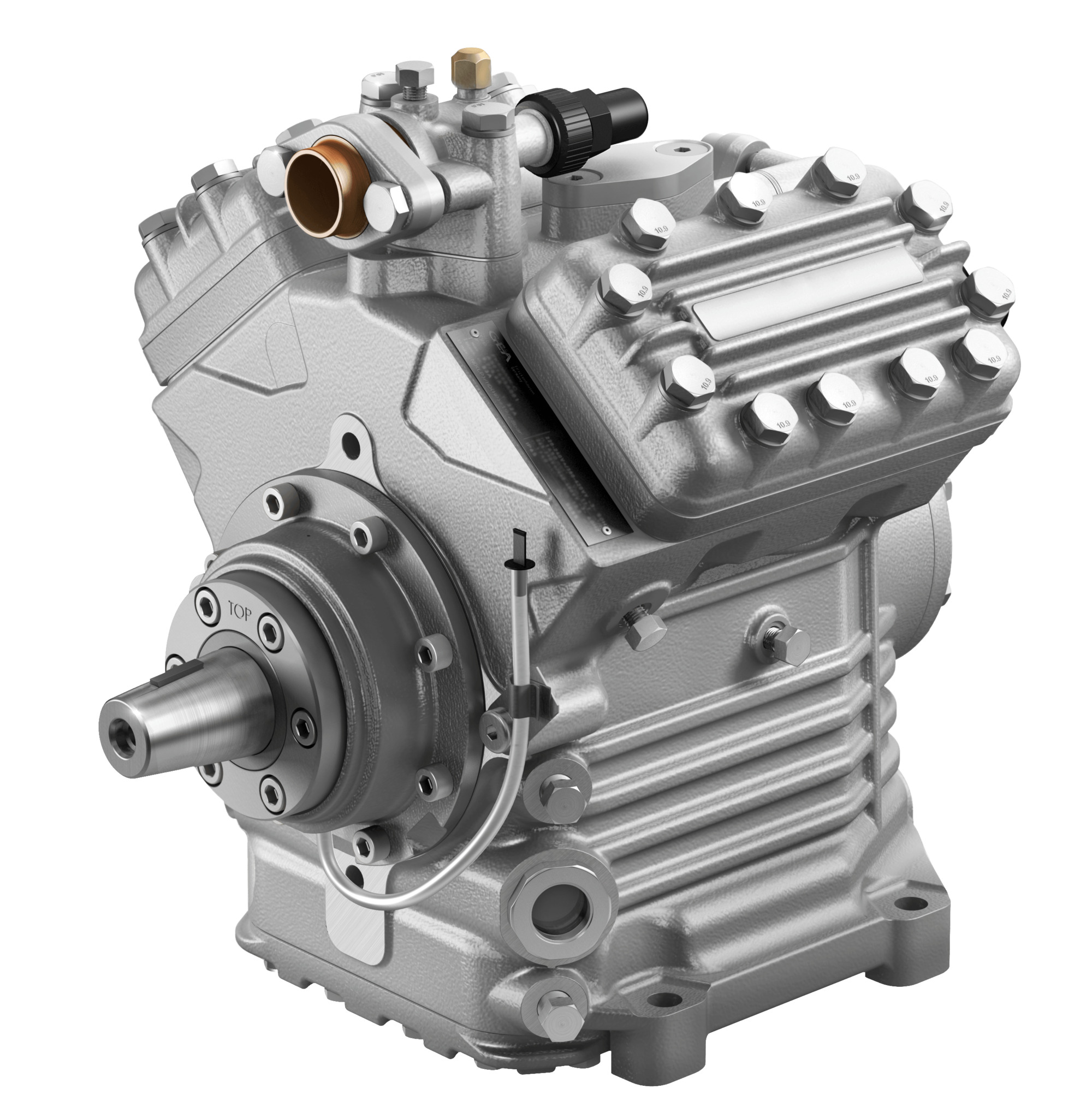

FK series - Vehicle compressors for mobile cooling

FK series - Vehicle compressors for mobile coolingDiscover Danfoss BOCK®'s FK series compressors, the result of decades of expertise and innovation. Lightweight, robust, and versatile, these compressors excel in bus, rail, and transport cooling. Trust in the proven reliability of the FK40 and the series' ongoing adaptation to diverse refrigerants and application needs.

-

if (isSmallPicture) {

Semi-hermetic aluminium compressors for mobile use: HG HC series

Semi-hermetic aluminium compressors for mobile use: HG HC seriesDiscover Danfoss BOCK®'s innovative HG-series aluminum compressors, designed for mobile refrigeration. With a lightweight design, improved performance, space efficiency, and enhanced safety features, these compressors are ideal for bus air conditioning, electric applications, and railway transportation systems.

-

if (isSmallPicture) {

Semi-hermetic CO₂ compressors: HGX CO₂-series

Semi-hermetic CO₂ compressors: HGX CO₂-seriesDiscover Danfoss BOCK®'s eco-friendly excellence with semi-hermetic CO2 compressors. Our commitment to sustainability means efficient and reliable solutions for commercial and industrial refrigeration, air conditioning, heating, and more. Choose from versatile, high-pressure, and specialized compressors that meet environmental standards while ensuring peak efficiency and operational reliability

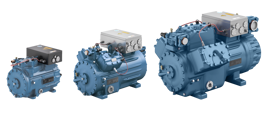

Compressors for stationary applications

The sustainable choice for all your HVAC-R needs with BOCK® semi-hermetic compressors from Danfoss. Our compressors lead the industry in commercial and industrial refrigeration, spanning air conditioning, heating, cooling, heat recovery, and heat pumps.

We are committed to a greener future, innovating efficient and reliable CO2 and low-GWP refrigerant compressors that combine functionality, economic efficiency, and environmental responsibility.

Explore the features and benefits, including natural refrigerants, CO2 applications, ATEX HC models, versatility, efficiency, reliability, and eco-friendliness. Welcome to the sustainable world of Danfoss BOCK® compressors.

Product range - Stationary applications:

-

if (isSmallPicture) {

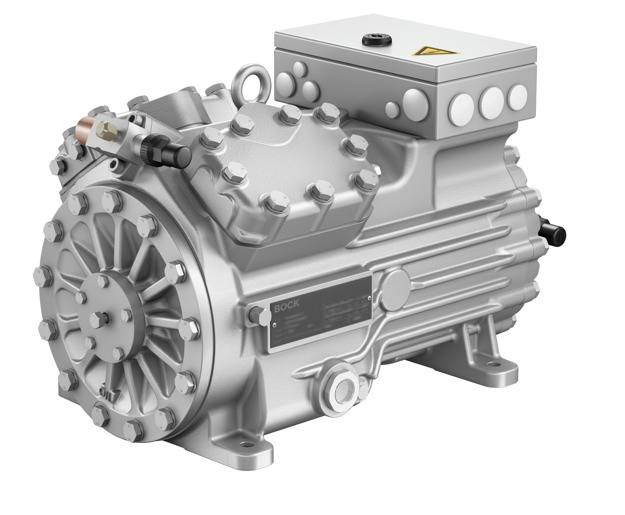

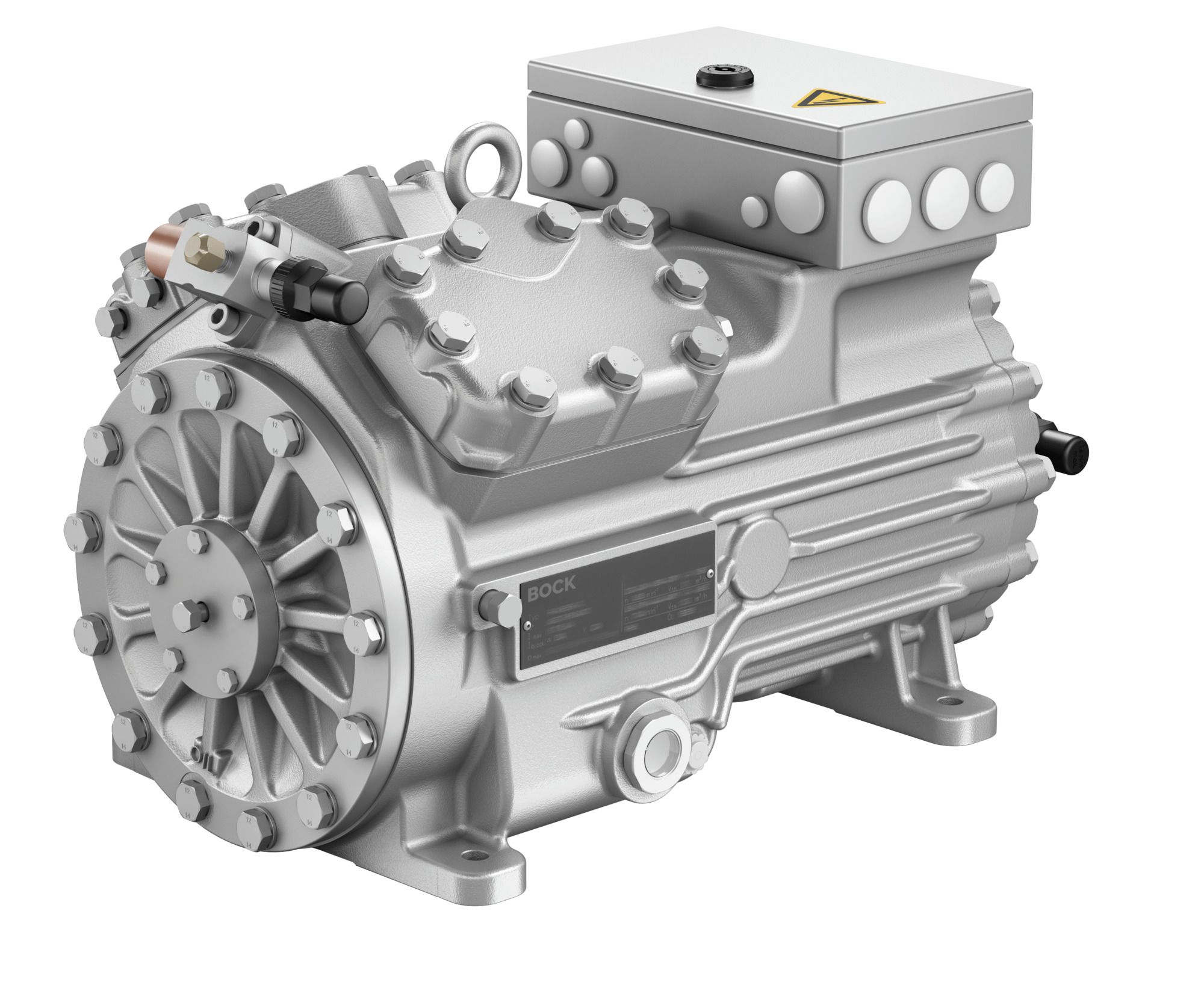

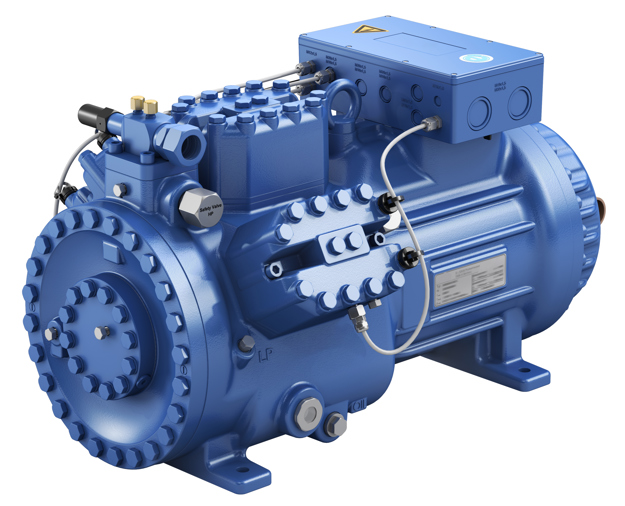

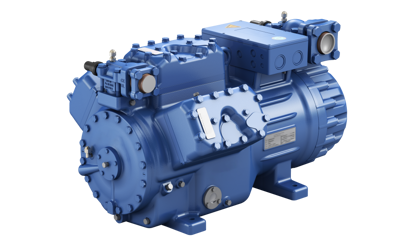

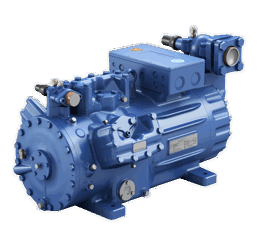

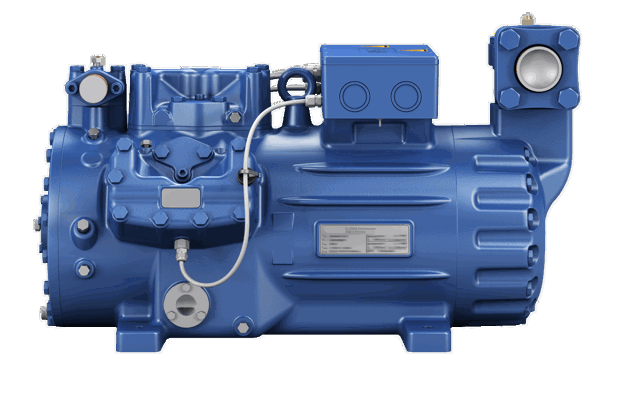

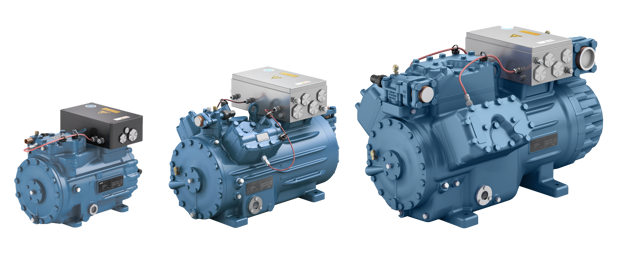

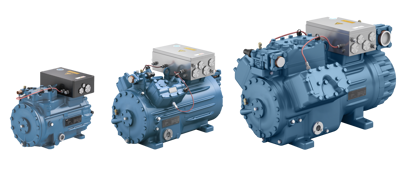

Semi-hermetic compressors: HG and HA-series

Semi-hermetic compressors: HG and HA-seriesExplore Danfoss BOCK®'s HG and HA compressor ranges, offering exceptional cooling efficiency and reliability. These compressors are designed for various refrigerants, feature improved efficiency, compact design, and energy savings, making them versatile solutions for refrigeration, air conditioning, and more.

-

if (isSmallPicture) {

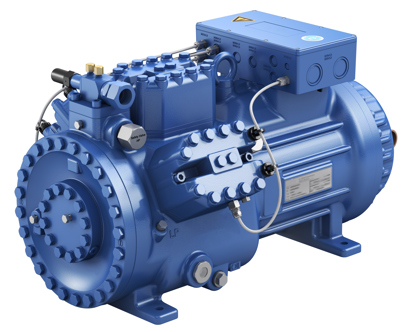

Semi-hermetic low-GWP compressors: HG LG-series

Semi-hermetic low-GWP compressors: HG LG-seriesExplore Danfoss BOCK®'s LG compressor range, designed for low-GWP HFO refrigerants, delivering reliable, efficient, and eco-friendly cooling solutions. With global regulation compliance, specialized technology, and a comprehensive range, trust in our decades of expertise for sustainable refrigeration and air conditioning

-

if (isSmallPicture) {

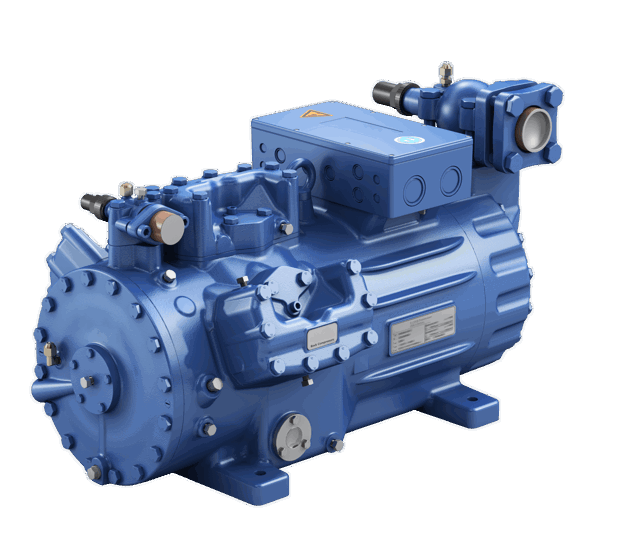

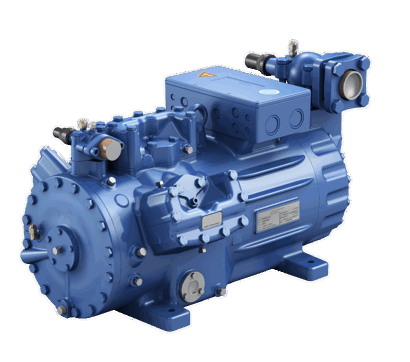

Semi-hermetic hydrocarbon compressors: HG HC-series

Semi-hermetic hydrocarbon compressors: HG HC-seriesExperience the natural choice in refrigeration with Danfoss BOCK®'s hydrocarbon compressors. Designed for efficiency and sustainability, these compressors offer a reliable, long-life design with a wide and safe operating range. Optimize your total cost of ownership and embrace eco-friendliness in applications like supermarket refrigeration and chillers with BOCK® HC compressors.

-

if (isSmallPicture) {

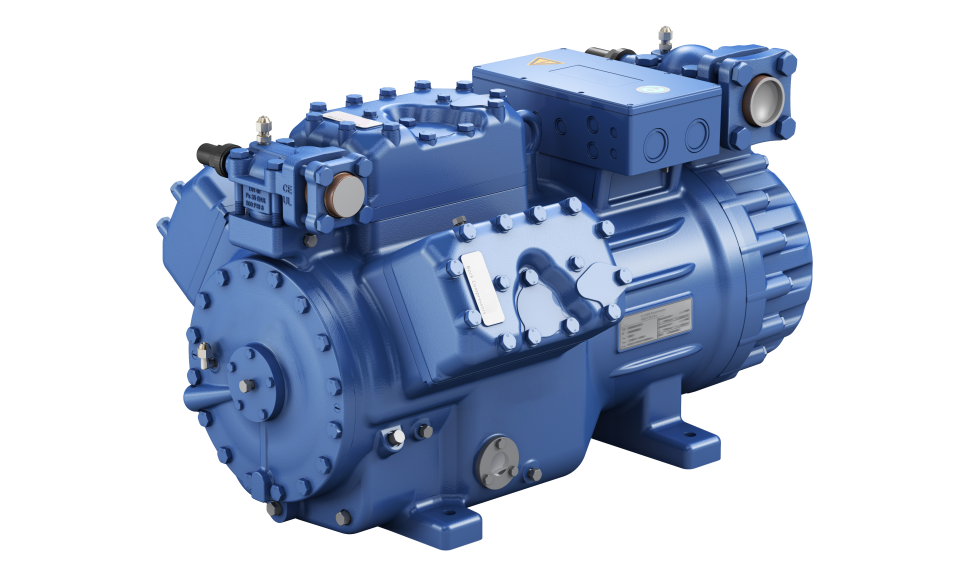

Semi-hermetic CO₂ compressors: HGX CO₂-series

Semi-hermetic CO₂ compressors: HGX CO₂-seriesDiscover Danfoss BOCK®'s eco-friendly excellence with semi-hermetic CO2 compressors. Our commitment to sustainability means efficient and reliable solutions for commercial and industrial refrigeration, air conditioning, heating, and more. Choose from versatile, high-pressure, and specialized compressors that meet environmental standards while ensuring peak efficiency and operational reliability

-

if (isSmallPicture) {

Semi-hermetic ATEX compressors: EX-HG-series

Semi-hermetic ATEX compressors: EX-HG-seriesDanfoss BOCK® leads in ATEX/IECEx compliant compressors for explosive atmospheres in zones 1 and 2. Our semi-hermetic HG series compressors offer explosion-proof reliability, stringent quality standards, and customer-centric solutions, ensuring safety and efficiency in hazardous environments.

Condensing units

-

if (isSmallPicture) {

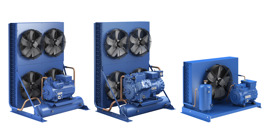

BOCK® condensing units

BOCK® condensing unitsBOCK® condensing units are designed for extreme conditions as these units excel in both cold and scorching hot regions. They maintain efficiency without compromising on performance, thanks to adaptive heat exchangers and efficient AC fans.

Software

Compressor selection tools - VAP

The VAP tools are ideal for finding the appropriate compressors or units for stationary and mobile applications. By inputting the required refrigerating capacity and operating conditions, the tool will display compatible components right away. In the VAP tools you will also find additional details about the suggested compressors.

Cases

-

if (isSmallPicture) {

Harvesting heat from below: Groundwater's secret power

Harvesting heat from below: Groundwater's secret powerBiel, a dedicated Energy City since 2008, employs an eco-friendly heating network that extracts heat from abundant groundwater. Using R1234ze, a low-impact refrigerant, heat pumps significantly reduce CO2 emissions.

-

if (isSmallPicture) {

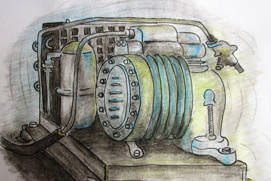

Hugo the compressor, our work horse

Hugo the compressor, our work horseToo fit to slow down. Still fit, with over 160,000 operating hours behind it: Hugo the compressor purrs like it did on the first day. Hugo is an HK2C type semi-hermetic compressor, built in 1955. It has one cylinder and runs at 1,450 revolutions per minute. It is named after Hugo Bock who, together with company founders Wilhelm Bock and Erich Etter, was managing the company when Hugo was built.

-

if (isSmallPicture) {

Going Green in tight spots: Natural Refrigerant Conversion

Going Green in tight spots: Natural Refrigerant ConversionGlobal Seas' Northern Defender trawler upgraded its refrigeration system with a compact CO2 solution for eco-friendly and cost-effective seafood chilling. The CO2 system's compactness, equipped with BOCK compressors and frequency converters, maximized efficiency and capacity within tight onboard spaces. This successful project has opened the door for more CO2 refrigeration systems on ships, providing space-saving, eco-friendly alternatives.

-

if (isSmallPicture) {

Art guardians: Climate's silent protectors

Art guardians: Climate's silent protectorsThe Suermondt-Ludwig Museum in Aachen needed to maintain a constant indoor temperature of and a relative humidity. In addition, it had to be environmentally friendly, energy-efficient, and utilize a climate-friendly refrigerant. The solution was transcritical CO2 chillers, each equipped with two Bock compressors using CO2 as the refrigerant. This project successfully combines art preservation with eco-friendliness and energy efficiency.

-

if (isSmallPicture) {

Embracing CO₂ innovation: Partnering for a sustainable future in Latvia

Embracing CO₂ innovation: Partnering for a sustainable future in LatviaIn an exclusive interview, Mr. Roberts Taubergs, Technical Director of SIA Vega 1 Serviss, shares insights into their successful project with BOCK CO2 compressors in Latvian supermarkets, highlighting the growing trend towards CO2-based solutions.

-

if (isSmallPicture) {

Pioneers: Field-testing the future

Pioneers: Field-testing the futureBOCK upgraded their air-conditioning system using propane, increasing cooling efficiency for hot summers. The system also facilitated the development of the HG66e HC compressor, which is now in full production. Propane operates smoothly, even during hot summers, and offers individual temperature control for employees.

Contact us

Need more information?

Do you need more information about BOCK® Compressors - or support with a project?

Find the nearest BOCK® Sales & Services location and contact us