Ensure maximum production and efficiency

Boost overall performance and energy efficiency of your AC drive system by replacing outdated AC drives with the latest technology.

With the proactive approach of planning the replacement well in advance, you can fit the retrofit into your timeline and adjust for any production restrictions that may occur. This keeps your production running with minimum delay, and you can enjoy a reliable budget without unexpected costs.

How it works

Features and benefits

Adopt the latest technology with the right drive for the application

- Achieve additional process and energy efficiency in your existing system

- Only pay for what you need

- 100% compatibility and durability

- Ensure best protection for your other equipment

Coordinated replacement of large volumes of AC drives

- Mitigate installation costs

- Benefit from Danfoss expertise to ensure fast and easy replacement selection, commissioning, and maintenance planning

Replacement schedule

- Efficiently replace the outdated products with latest technology AC drives

- Ensure maximum uptime with careful planning

- Avoid unexpected cost for emergency drive support

FAQ

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Fact sheet | DrivePro Retrofit | English | Multiple | 17 Jul, 2024 | 1.0 MB | |

| Fact sheet | DrivePro Retrofit - Austria | German | Austria | 26 Apr, 2022 | 1.0 MB | |

| Fact sheet | DrivePro Retrofit - Chinese | Chinese (CN) | Multiple | 25 Sep, 2024 | 646.2 KB | |

| Fact sheet | DrivePro Retrofit - Czech | Czech | Multiple | 26 Apr, 2022 | 1.0 MB | |

| Fact sheet | DrivePro Retrofit - Danish | Danish | Multiple | 26 Apr, 2022 | 1.0 MB | |

| Fact sheet | DrivePro Retrofit - Dutch | Dutch, Flemish | Multiple | 26 Apr, 2022 | 1.0 MB | |

| Fact sheet | DrivePro Retrofit - Finnish | Finnish | Multiple | 26 Apr, 2022 | 1.0 MB | |

| Fact sheet | DrivePro Retrofit - French | French | Multiple | 25 Sep, 2024 | 599.0 KB | |

| Fact sheet | DrivePro Retrofit - German | German | Multiple | 25 Sep, 2024 | 610.8 KB | |

| Fact sheet | DrivePro Retrofit - Hungarian | Hungarian | Multiple | 26 Apr, 2022 | 1.0 MB | |

| Fact sheet | DrivePro Retrofit - Italian | Italian | Multiple | 25 Sep, 2024 | 588.3 KB | |

| Fact sheet | DrivePro Retrofit - Korean | Korean | Multiple | 26 Apr, 2022 | 999.4 KB | |

| Fact sheet | DrivePro Retrofit - Polish | Polish | Multiple | 26 Apr, 2022 | 1.0 MB | |

| Fact sheet | DrivePro Retrofit - Portuguese | Portuguese | Multiple | 25 Sep, 2024 | 590.1 KB | |

| Fact sheet | DrivePro Retrofit - Romanian | Romanian, Moldavian, Moldovan | Multiple | 26 Apr, 2022 | 1.0 MB | |

| Fact sheet | DrivePro Retrofit - Russian | Russian | Multiple | 26 Apr, 2022 | 1.0 MB | |

| Fact sheet | DrivePro Retrofit - Slovak | Slovak | Multiple | 26 Apr, 2022 | 1.0 MB | |

| Fact sheet | DrivePro Retrofit - Spanish | Spanish, Castilian | Multiple | 25 Sep, 2024 | 595.1 KB | |

| Fact sheet | DrivePro Retrofit - Switzerland | German | Switzerland | 26 Apr, 2022 | 1.0 MB | |

| Fact sheet | DrivePro Retrofit - US English | English | United States | 19 Sep, 2024 | 497.6 KB |

Case stories

-

if (isSmallPicture) {

DrivePro® services ensure reliable uptime for Sapio Group

DrivePro® services ensure reliable uptime for Sapio GroupITALY: Sapio Group, Italy's leading producer of industrial and medical gases, uses condition monitoring (CBM) and DrivePro® services to ensure reliable uptime for gas supply to a semiconductor manufacturer.

-

if (isSmallPicture) {

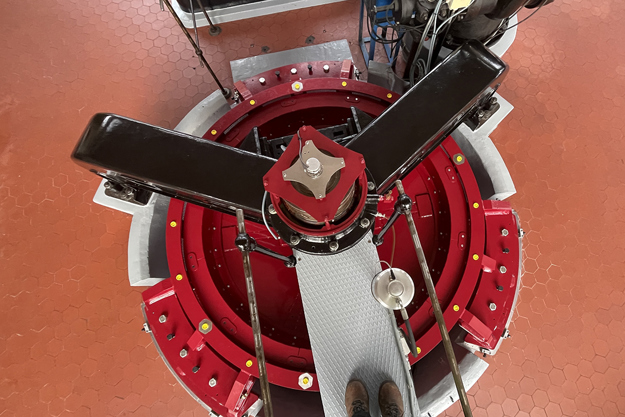

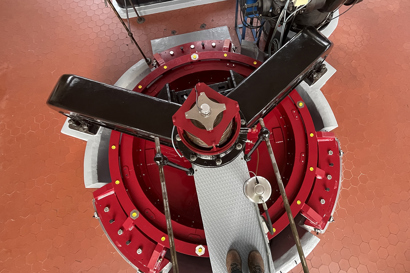

Unlocking efficiency with a drive retrofit at a Czech hydropower plant

Unlocking efficiency with a drive retrofit at a Czech hydropower plantCZECHIA: When 80-year-old gears were replaced by variable speed control at the Albrechtice hydropower plant, power production increased by 10%.

-

if (isSmallPicture) {

Wind tunnel achieves 99.5% uptime with Danfoss DrivePro®

Wind tunnel achieves 99.5% uptime with Danfoss DrivePro®Belgium: Thanks to Danfoss DrivePro® services, LuxFly has achieved 99,5% uptime in Europe’s largest vertical wind tunnel that is used for skydiving.

-

if (isSmallPicture) {

DrivePro® Lifecycle Services secure maximum uptime for Rothes CoRDe

DrivePro® Lifecycle Services secure maximum uptime for Rothes CoRDeSCOTLAND: The Rothes CoRDe plant, a biomass-fired combined heat and power (CHP) plant, ensured maximum uptime thanks to several DrivePro® Lifecycle Services.

-

if (isSmallPicture) {

Refrigeration systems preserve apple quality using VSDs with integrated condition monitoring and DrivePro Remote Monitoring service

Refrigeration systems preserve apple quality using VSDs with integrated condition monitoring and DrivePro Remote Monitoring serviceITALY: At Rivoira Group, VLT® drives with built-in condition-based monitoring help preserve fruit perfectly by ensuring utterly reliable refrigeration.

-

if (isSmallPicture) {

Site assessment secures maximum uptime for K+S

Site assessment secures maximum uptime for K+SGERMANY: Thanks to DrivePro® Life Cycle Services, a K+S potash mine got more uptime and a quick retrofit resulting in a better bottom line.