Designing our products towards a circular economy

As the economy continues to grow with rapid urbanization as one driver, there is a growing demand for more products, which, in turn, means more raw materials need to be extracted, and more waste is produced.

We strive to deliver the best circular solutions on the market by developing innovative circular business models with our customers and suppliers.

Our ambition is to drive this change by refining how we design our products. Examples include increasing recycled content in the raw materials in our products and collaborating with our customers on new business models, such as takeback, remanufacturing, and refurbishing.

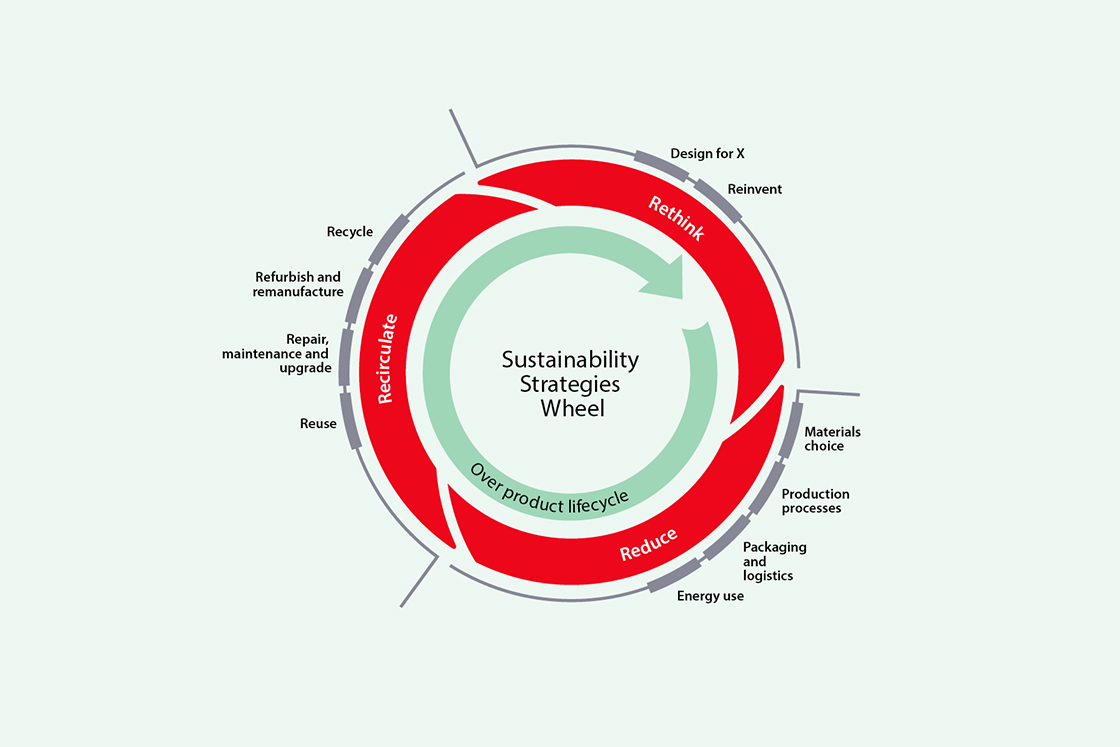

Danfoss’ Rethink-Reduce-Recirculate approach drives the innovation and development of our new products.

'Rethink' entails changing the business model and the way a product is offered to the market. This can include changes to the design of the product or the business model so that, for example, a service is offered instead of a product.

'Reduce’ involves decreasing material and energy consumption or switching to greener alternatives during the manufacturing stage, the sourcing of raw materials, logistics and packaging operations.

'Recirculate' involves ensuring products and materials are used as much as possible before their end of life. This approach involves two aspects; one focuses on products and parts recirculation through reuse, refurbishment, remanufacturing, or upgrading, and the other on materials through recycling.

We have developed the Danfoss Circularity Framework that centers on these principles and incorporated ten circularity strategies. Together with our newly developed Sustainable Design Guide they will support our engineers in developing new products and will guide improvements in our existing portfolio.

The Danfoss Circularity Framework and approach is supported by a newly developed toolbox, to accelerate the integration of circularity into our new product development. The toolbox includes:

- Sustainable Design Guide: operationalizes the Danfoss Circularity Framework, providing guidelines and practical examples for implementation

- Danfoss RE:CIRC tool: assesses the sustainability of a product, supporting our R&D teams to identify high-impact design improvements

- Green Materials Guide: circularity and carbon data on materials and applications to inform our materials choices

- Carbon Footprint tool: calculates the lifecycle carbon footprint of potential products

- Circularity Index tool: measures the circularity potential of products

- Sustainable Packaging tool: assesses the sustainability of packaging options

In 2024, we rolled out the circularity toolbox across Danfoss. Using our RE:CIRC, circularity index, and carbon footprint tools, our innovation teams apply the 10 sustainable design strategies from the Danfoss Circularity Framework to support the innovation process.

Our circularity targets for 2030:

Collaborating for circularity

The transition to a circular economy requires a holistic approach, and therefore, we actively work to foster partnerships with our suppliers, customers, and business partners. We do this, for example, through our supplier engagement program, through which we have worked with suppliers to identify opportunities to increase the use of recycled materials.

We leverage our partnerships to help scale circular economy initiatives across our industry and raise awareness. Together with the Ellen MacArthur Foundation, we have established a network-led project on circular metrics. We participate in the Circular Design Forum and the Nordic Circularity Accelerator and help shape common definitions in the industrial sector for product circularity. We have co-funded a research project on circular electronics that aims to develop tools to support product designers in designing for X (e.g., disassembly or reuse).

Collaboration with customers

Collaboration across the entire product’s life cycle is key in order to drive change on circularity. This is why one of our targets for 2030 focuses on customer collaborations, as we see them as an enabling factor towards this journey.

In Denmark, up to 500,000 thermostats are discarded as waste every year. Danfoss Climate Solutions aims to reduce waste and increase the recycling of these materials. Therefore, in 2024, we tested options for recycling thermostat materials at end of life. We invested in a take-back pilot to explore options for introducing these materials into new Danfoss products, enabling significant emissions reductions. Through customer collaboration, we established 10 collection points in Denmark. The recycled contents will go into new thermostats of the same high-quality Danfoss is known for but with significantly lower embodied emissions.

Reducing waste and resources

We are continuously improving the efficiency of our manufacturing, reducing the waste produced, and ensuring proper recycling. We also find alternative raw materials that have reduced environmental impacts or come from waste.

We aim to minimize both hazardous and non-hazardous waste in our own operations. We have released a Waste Management Policy that defines reporting dimensions and responsibilities for the Danfoss Group. To support the reporting process, we have developed a global reporting tool to improve the data collection process. We apply the Rethink-Reduce-Recirculate principles to our waste management, aiming to increase the reused and recycled content in our products and reduce landfill waste. Moving forward, we will leverage this foundation to establish a unified ambition for waste minimization, including defining clear targets.

First Movers Coalition

In November 2023, Danfoss announced our commitment to the First Movers Coalition (FMC). The goal of the Coalition is simple: Send a clear demand signal to accelerate emerging climate technologies in order to decarbonize the world’s heaviest emitting sectors.

Danfoss made the commitment to purchase at least 10% (by volume) of low-carbon primary aluminum by 2030. Additionally, we committed to ensuring that at least half of all aluminum used is composed of secondary aluminum by 2030.

Joining the First Movers Coalition goes hand-in-hand with our aim to be our customers’ preferred decarbonization partner. To bring products to market with a lower carbon footprint, we will continue to expand collaboration across our value chain.

About the First Movers Coalition:

- 90+ leading global companies

- A partnership between the US State Department and the World Economic Forum

- Represents EUR 14bn in annual demand, the world’s largest demand signal

- The seven hard-to-abate sectors covered by the

FMC accounts for 30% of total global emissions

Recirculating products and parts

Keeping products and materials in use for as long as possible by ensuring their durability, maintenance, repair and remanufacturing, can help reduce environmental impacts and consumption of virgin resources.

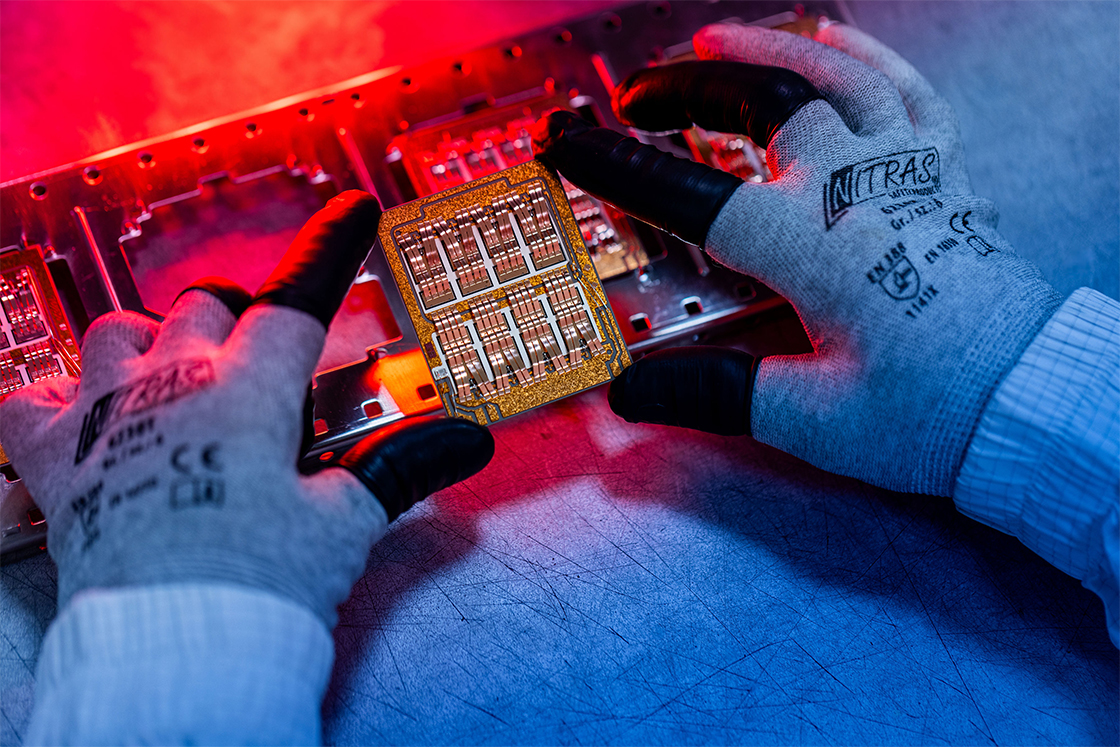

Through the digital service DrivePro®, Danfoss Power Electronics and Drives offers an array of services with a focus on circularity – such as exchange, retrofit, preventive maintenance, and repair – which have the potential to extend the lifetime of products, save virgin resources, and reduce CO₂ emissions. The DrivePro® service package is currently offered in 56 countries and markets and covers 95% of the segment’s product portfolio. DrivePro® is built to prolong and eventually close the loops of material circles. Refurbishing returned drives can make a significant impact, especially for industries grappling with the scarcity of virgin resources.

In India, the refurbishment of Drives started at the production facility. The drives received from our customers are cleaned, inspected, and refurbished to the original quality and performance specifications. Danfoss uses advanced manufacturing practices to ensure that refurbished products provide a like-new performance. We are looking into establishing standardized procedures in order to scale the project to other regions in the coming years. Remanufacturing a drive can save up to 90% of virgin material used and 88% of manufacturing carbon emissions.

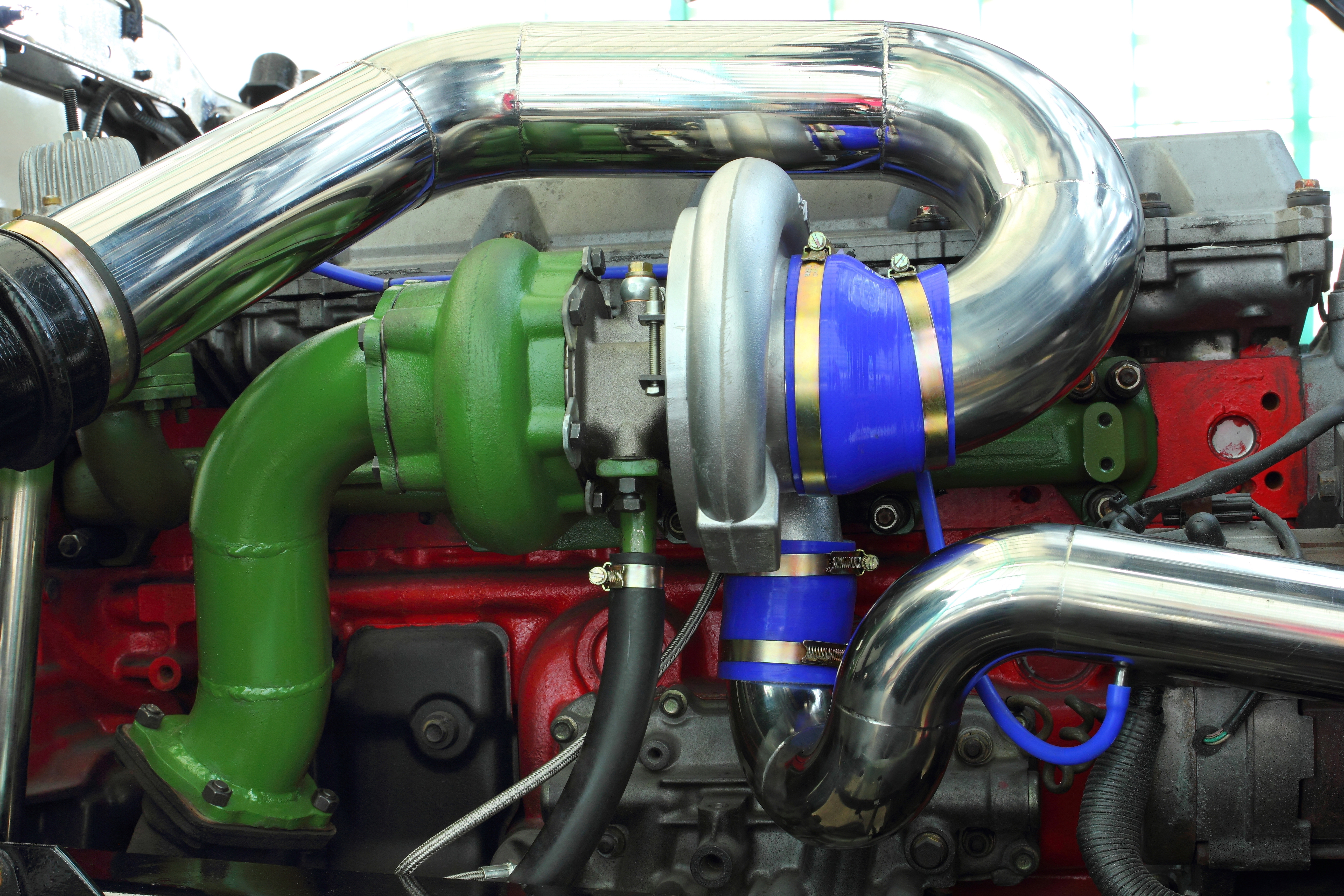

Refurbishment and reuse of drives is established practice in other Danfoss sites such as the Haiyan factory in China. In Danfoss Power Solutions in Brazil, we are piloting the expansion of our aftermarket service parts replacement program. The pilot program consists of three options: Maintenance, basic retrofit, and complete core replacement. S90 pumps are remanufactured to their original performance specifications through state-of-the-art salvage techniques, adhering to strict reuse guidelines, using advanced manufacturing systems, and following robust quality control. The newly remanufactured Danfoss S90 pumps then re-enter the supply chain with their lifecycle restarted, and ready to be installed.

Remanufacturing is one important lever for meeting decarbonization and circularity objectives. It represents an example of identifying a new business opportunity to continue to increase our aftermarket sales while maintaining high standards of quality of the products we provide to our customers. Remanufacturing products goes beyond simple repair as it is the re-engineering of products and components to as-new condition with the same or improved level of performance as a newly manufactured product.

Danfoss Power Solutions offers a repair and remanufacturing service for many products. This service is available in selected locations in the US and Europe. In the US, there is a focus on piston products (pumps and motors) and valves.

Annual Report 2024

Our integrated annual report provides a holistic view of Danfoss’ business, value drivers, strategy, governance, as well as sustainability and financial performance.