Water and energy loss put pressure on the water industry

According to World Economic Forum 2017, a water crisis is evaluated as one of the highest risks to the world and with the largest impact.

As populations grow, pressures mount and finding a more sustainable relationship between water and energy supplies become critical in less than two decades.

Today, close to one third of the world’s population is estimated to live in water stressed and scarcity areas and by 2040, almost 20 % of all countries are anticipated to experience extremely high water stress.

Yet, water and energy loss in the water sector are extremely high. In fact, the average amount of water wasted by waterworks is 40 % worldwide and 26 % in Europe – due to errors, leakages, and water pressure.

At the same time, 4 % of global electricity is consumed by the water industry – a figure that is expected to double by 2040 – and water accounts for up to half of a municipality’s total energy bill.

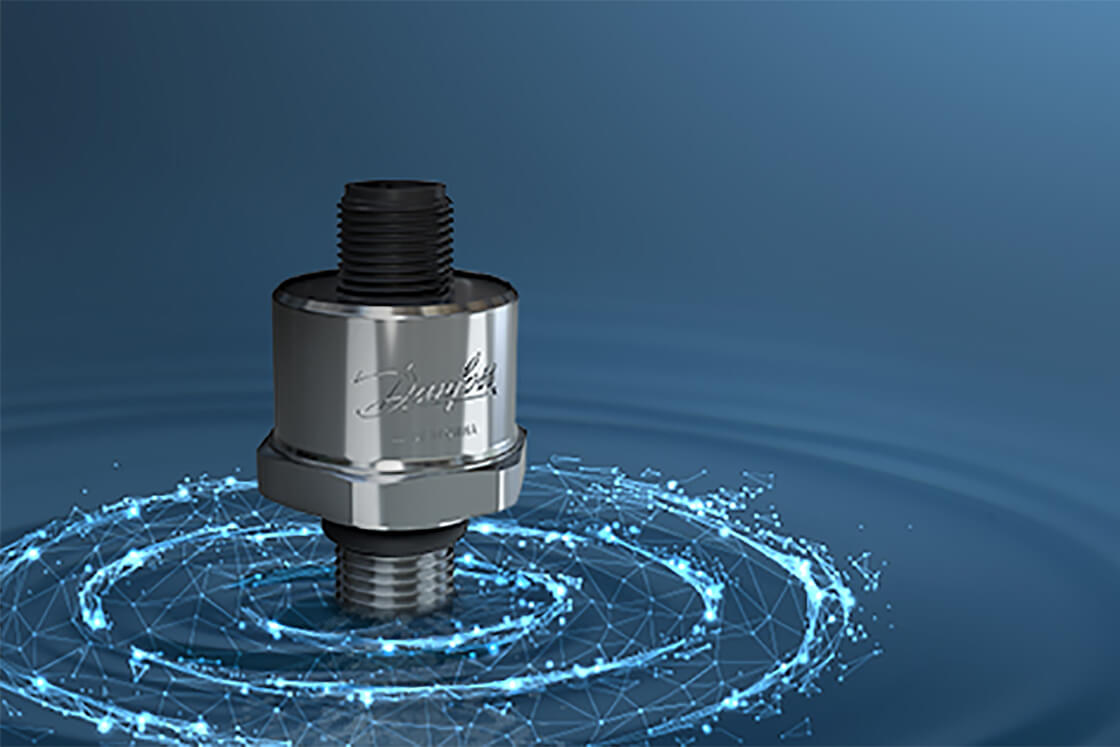

Meet the DST P10B #CANopen pressure transmitter featuring an embedded communication module.

This means you can access new sensor data and optimize application performance.

New DST P140 Pressure Transmitter

The DST P140 pressure transmitter is designed to provide unrivaled reliability, durability, performance, and not least, digital possibilities in the water-pump market.

Today’s challenges Tomorrow’s achievements

The industry challenges reflect a growing need for efficient water supply and treatment.

The good news is that technologies to reduce energy consumption and leakages in all stages of the water cycle – from production and distribution to wastewater pumping and treatment – already exist.

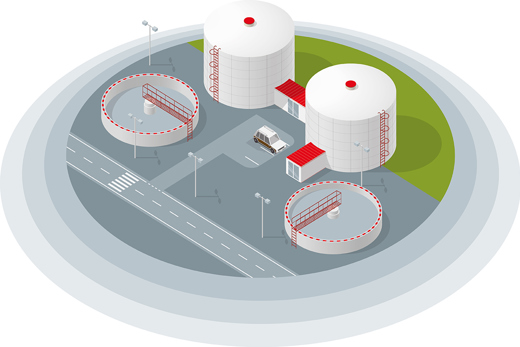

Pressure management is key throughout the water cycle

Global Director at Danfoss Drives Segment, Mads Warming, explains why there is a need for more efficient water supply and treatment on a global scale.

Pressure control is key to reduce water and energy loss

Danfoss pressure sensors and variable speed drives are a key component for reducing water and energy loss throughout the whole water cycle.

Experiences from 112 systems in 10 different countries show that better pressure control reduces non-revenue water and unnecessary energy consumption significantly.

In average, improved pressure management leads to 38 % reduction in pressure and 53 % less new breaks. Among other benefits, the energy consumption is reduced by 20-40 % and the typical water leakage reduction is 38 %. Moreover, the improvements result in extended asset lifetime and fewer network related complaints.

Danish water utility sets new standards for sustainability

The Danish water utility, Aarhus Water, is running with only 6 % leakage. Danfoss has contributed through the whole water cycle.

Bringing water and energy use into balance

The increasing global demand for water and energy has put immense pressure on both industries to find a path towards a more sustainable future. And pressure itself is the key to achieving this goal.

Related products

-

if (isSmallPicture) {

VLT® AQUA Drive FC 202

VLT® AQUA Drive FC 202VLT® AQUA Drive FC 202 controls all types of pumps and comes equipped with a cascade controller.

-

if (isSmallPicture) {

MBS 4010 flush diaphragm pressure transmitter

MBS 4010 flush diaphragm pressure transmitterThe high accuracy flush diaphragm pressure transmitter MBS 4010 is designed for use in non-uniform, high viscous or crystallizing media within industrial applications, and offers a reliable pressure measurement, even under harsh environmental conditions.

-

if (isSmallPicture) {

DST P10B CANopen, Smart Sensor pressure transmitter with an CANopen DS 301/DS 404 communication profile

DST P10B CANopen, Smart Sensor pressure transmitter with an CANopen DS 301/DS 404 communication profileThe DST P10B CANopen pressure transmitter built on the DST P1XX product range with a CANopen DS 301/DS 404 communication profile—empowering you to add sensors to your existing high-level fieldbus communication in water distribution, air compressor, and HVACR applications.

-

if (isSmallPicture) {

MBS 3000 general purpose pressure transmitters

MBS 3000 general purpose pressure transmittersMBS 3000 is designed for use in almost all industrial applications, and offers a reliable pressure measurement, even under harsh environmental conditions.

The flexible pressure transmitter programme covers all standard output signals. -

if (isSmallPicture) {

MBS 1900, pressure transmitter for air and water applications

MBS 1900, pressure transmitter for air and water applicationsThe pressure transmitter MBS 1900 is designed for use in air and water applications like booster pumps and air compressors. The flexible pressure transmitter program covers different output signals, absolute and gauge (relative) versions, measuring ranges from 0-4 bar to 0-25 bar and a wide range of pressure and electrical connections. Enclosure material is stainless steel AISI 316L.

Case stories

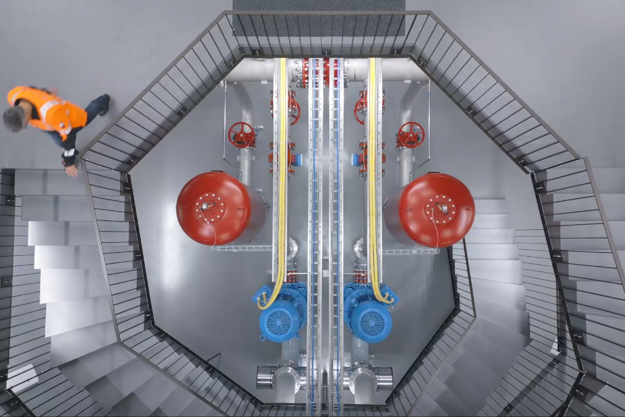

The worldwide first energy-neutral catchment area

The Marselisborg catchment area in Aarhus has achieved 100 % energy surplus production - by minimizing consumption throughout the whole water cycle and maximizing energy production from the wastewater facility.

Articles

-

if (isSmallPicture) {

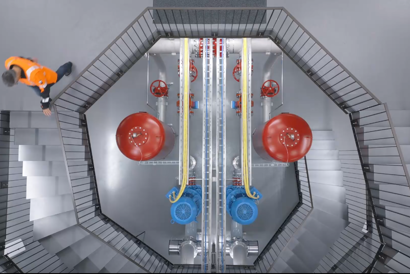

How a new water pumping station keeps supply flowing in Bern

How a new water pumping station keeps supply flowing in BernSWITZERLAND: The Wehrliau pumping station in Bern delivers up to 1.20 M liters of drinking water hourly. iC7 drives play a key role in ensuring reliable supply.

-

if (isSmallPicture) {

Carlsberg brewery drives down energy consumption

Carlsberg brewery drives down energy consumptionPOLAND: For more than a decade, Danfoss drives have reduced the power consumption at Carlsberg’s Okocim Brewery. The brewery uses less water and has lowered its emissions, too.

-

if (isSmallPicture) {

Driving efficient life support systems at Lodz Zoo

Driving efficient life support systems at Lodz ZooPOLAND: The Lodz Zoo Orientarium uses high-efficiency VLT® AQUA Drive FC 202 to secure reliable water quality in life support systems for rare animal species.

-

if (isSmallPicture) {

Danfoss drives prevent coastline flooding

Danfoss drives prevent coastline floodingNETHERLANDS: Efficient variable speed pump control using drives from Danfoss is the key to reliable flood prevention in Noordoostpolder municipality in the Netherlands.

-

if (isSmallPicture) {

Danfoss efficiencies help South African farmer to free up energy and achieve production goals

Danfoss efficiencies help South African farmer to free up energy and achieve production goalsSOUTH AFRICA: Discover how a South African farmer achieves 155,000+ kWh in annual energy savings thanks to a collaboration between Danfoss and BMG.

-

if (isSmallPicture) {

Rock-solid reliability underpins sustainable aquaculture at Nordlaks

Rock-solid reliability underpins sustainable aquaculture at NordlaksNORWAY: VLT® AQUA Drive FC 202 ensures dependable uptime with stringent harmonic compliance at Nordlaks Smolt AS.

Contact us

For further information, please contact us.