Forward. Naturally. With industrial CO₂ refrigeration solutions

How large CO₂ solutions will benefit Industrial Refrigeration

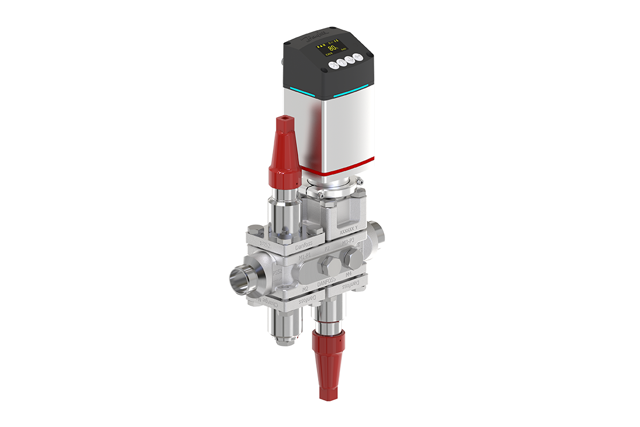

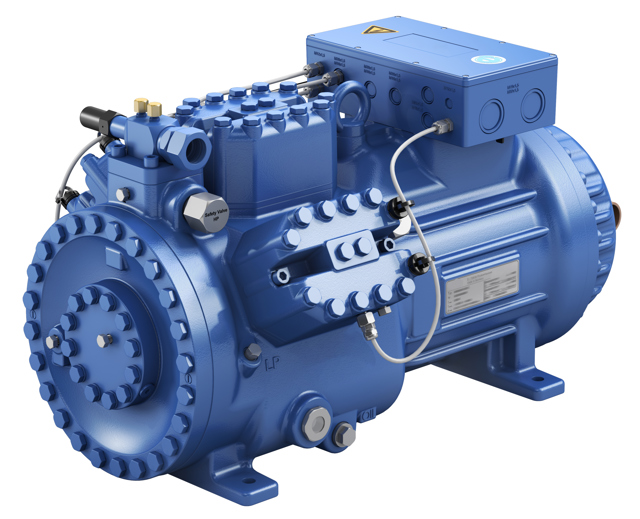

Use the parts designed for the job. Danfoss’ built-for-purpose, built-for-industry, transcritical CO2 solutions ensure your operation is future-proof. The larger components bring unmatched efficiency and simplicity to large systems. Creating a new industrial standard for transcritical CO2 systems.

Transcritical CO₂ simplified. Start your complexity-free journey in natural refrigerants with Danfoss.

The right, well designed CO2 system can be sustainable and energy efficient in application that requires cooling load, Whether you are exploring CO2 solutions for the first time or want to upgrade an existing operation, we are here to help.

From cascade installation to transcritical system, we provide larger components elliptically built for the job . With decades of experience in CO2 and industrial refrigeration, Danfoss offers knowledge and expertise for industrial refrigeration companies to ensure the optimal performance of your refrigeration system. Introducing a high industrial standard and improved efficiency.

Partner with Danfoss, and let us guide you towards a future where industrial refrigeration seamlessly integrates sustainability, energy efficiency, and top-notch performance with CO2 as the refrigerant.

Explore industrial CO₂ refrigeration systems in depth

Uncover performance disparities among various large-scale refrigeration systems with our comprehensive study. Delve into diverse system designs, revealing insights into energy consumption and overall costs through a detailed side-by-side comparison.

A closer look at transcritical refrigeration

Get a deeper view of transcritical systems for industrial refrigeration. In this white paper, learn how to seamlessly integrate single or multiple CO2 transcritical racks with subcritical CO2 pump-circulated and DX systems.

Expert Talk

Welcome to our 'Expert Talks' video series, where we break down the essentials of industrial refrigeration. In 'Embracing CO₂ in Industrial Refrigeration,' we discuss the shift to natural refrigerants. 'Building Industrial CO₂ Transcritical Systems: Key Considerations' walks you through the critical point for constructing top-notch CO₂ systems. Curious about efficiency? Tune into 'CO₂ Transcritical vs. Other natural refrigerants' for a straightforward comparison. Join us for practical insights that matter in the world of industrial refrigeration – no-nonsense, just expertise.

Products overview:

Explore the complete range of industrial CO₂ solutions.

Benefit from Danfoss’ two decades of expertise in developing industrial solutions specifically designed for CO2 systems. Our comprehensive portfolio includes a wide array of products meticulously engineered to cater to the demands of sub and transcritical applications.

Meet our CO₂ expert

Jacob Lundholm, CO2 solutions manager

Industrial Refrigeration - Global, Danfoss Climate Solutions

Contact us:

Ready to take the next step in optimizing your industrial refrigeration solutions? Connect with us by filling out the form below.

Whether you have inquiries about our CO2 refrigeration system, need expert advice, or want to explore partnership opportunities, we're here to assist. Your questions and comments are important to us, and we look forward to engaging with you to find the best solutions for your specific needs.

Simply complete the form, and our team will get in touch with you promptly. Let's work together to enhance the efficiency and sustainability of your industrial refrigeration systems.