Did you know you can connect higher uptime with sustainability?

By lowering water use, reducing CO2 emissions, and optimizing reliability, Danfoss Drives can make your mining project more profitable and more sustainable.

Avoid expensive downtime with edge intelligence

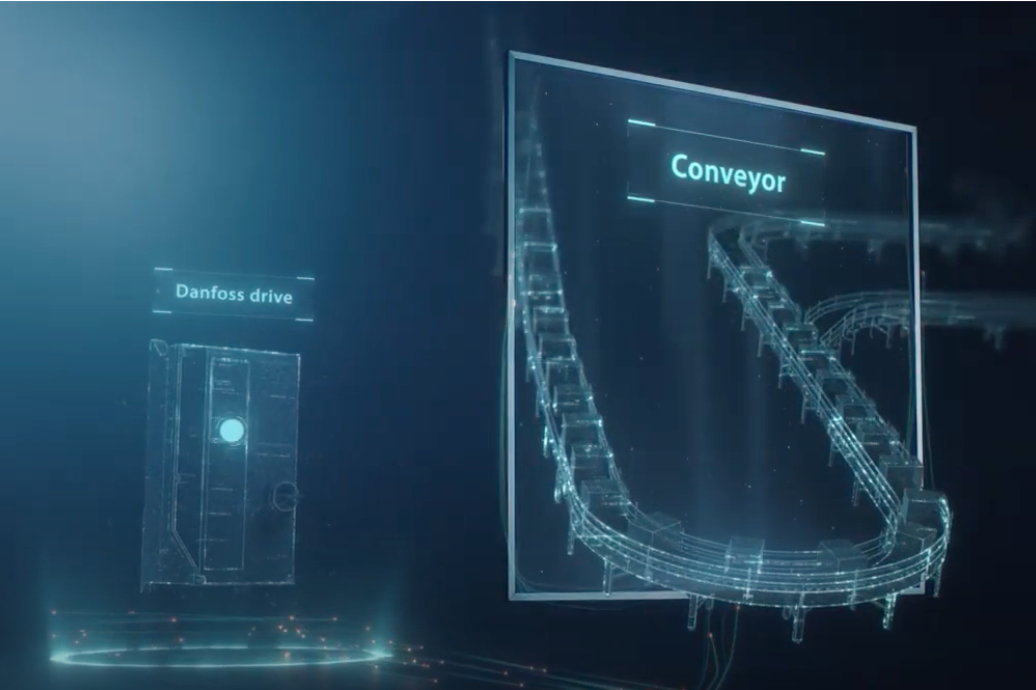

Danfoss Drives have more than 50 years of experience in making production plants and heavy industry operations more efficient. To reduce costly downtime, our edge-embedded intelligent drives keep conveyor belts running. Our drives empower you to predict unforeseen early failures by combining input from external sensors with internal data. Real-time data is analyzed on the edge to detect changes, transmit early warnings, and identify system degradation issues.

Unique condition monitoring of your mine

Maximize performance and minimize adverse application events at your mine with Danfoss intelligent drives. For most applications, no extra instrumentation is required. The drives enable you to significantly lower the total cost of your IoT solution just by distributing relevant data. Our intelligent drives connect with multiple input sources, such as the Programmable Logic Controller (PLC), on-premise systems, or the cloud, to accurately control speed.

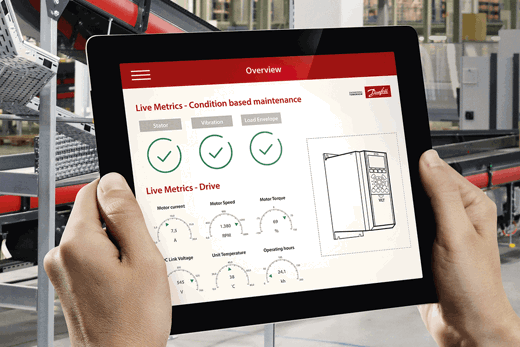

Gain independence and control with condition-based monitoring

Intelligent drives from Danfoss monitor, analyze and interpret data gathered from internal and external sensors to optimize your site and system performance and predict its maintenance needs. Key insights are then sent to any destinations specified by you, to give you full independence and control of your system.

Intelligent drives from Danfoss securing higher uptime

Cloud and advanced analytics

To meet ever-changing mining production and application specific needs, Danfoss intelligent drives connect with any cloud or analytics platform to bring intelligence, as well as condition-based and predictive maintenance, to your entire system.

Improved data security

By applying intelligence close to the data source and processing data on the edge, our intelligent drives increase data protection throughout your mining operation. They avoid the transmission of raw data to the cloud, on-premises data-storage or automation system, which reduces the amount of data at risk of interception or compromise.

Reduced investment

You can use the drive as a smart hub for external sensors at your mine, such as vibration sensors and pressure sensors, to enable condition-based monitoring and process control. As you only need one drive from Danfoss to create a hub, you can avoid spending on additional sensors and gateways.

Lower data cost

Streaming and processing raw data in the cloud can be costly. Distributing intelligence and processing data on the edge means you can send pre-processed data, which reduces bandwidth and simplifies data analysis in the cloud.

Open and independent

Our drives work with any kind of motor technology needed in your mining production, no matter whether it’s an induction, permanent magnet, or reluctance motor. You have the freedom to choose the best motor technology for your application. You’ll also be able to run the motor at maximum efficiency and performance.

Case stories

Danfoss VACON® drives cut energy consumption

Thanks to VACON® AC drives, Yamana gold mine enjoys a 30% energy reduction in energy consumption for its underground ventilation and pumping systems.

Meet our heavy industry experts

Contact us

One of our heavy industry experts will reach out to find the help or answer you need.

Products

Drives for mining applications

-

if (isSmallPicture) {

VLT® AQUA Drive FC 202

VLT® AQUA Drive FC 202VLT® AQUA Drive FC 202 controls all types of pumps and comes equipped with a cascade controller.

-

if (isSmallPicture) {

VACON® NXP Air Cooled

VACON® NXP Air CooledDesigned for a broad range of demanding applications, focusing on higher power sizes and system drives.

-

if (isSmallPicture) {

VLT® AutomationDrive FC 301 / FC 302

VLT® AutomationDrive FC 301 / FC 302The VLT® AutomationDrive FC 301 / FC 302 is designed for variable speed control of all asynchronous motors and permanent magnet motors. It comes in a standard version (FC 301) and an advanced high dynamic version (FC 302) with additional functionalities.

-

if (isSmallPicture) {

VACON® 1000

VACON® 1000This air-cooled medium-voltage drive is ideal for general-purpose industrial MV applications, especially for variable torque loads such as pumps and fans in the low and mid-power range.

-

if (isSmallPicture) {

VACON® NXC

VACON® NXCAn enclosed drive designed for demanding applications that includes options for Active Front Ends and low harmonic solutions.