What is a variable frequency drive?

You could say, a VFD is the best friend of your electric motor. Variable frequency drives (VFDs) are intelligent control devices that ensure efficient operation of electric motors, to use less energy and reduce operating costs. At the same time, they extend equipment lifetime, optimize processes, and reduce maintenance requirements.

Did you know a VFD can help you to save on your energy bill? The VFD can dramatically reduce energy consumption when compared to direct-on-line (DOL) operation, where the motor runs at full speed regardless of the demand. Using a drive, power or fuel savings of 40% are common. Sometimes the savings are as much as 80%. The roll-on effect means that use of drives also reduces NOx emissions and CO2 footprint of the systems in which they are installed.

When you understand what a VFD is and how to use it, you can get closer to reaching your climate targets, as well as winning competitive advantage. That’s why a VFD is a great asset and friend - not only to your motors, but your whole business.

Key benefits of VFDs:

VFDs for energy efficiency: VFDs intelligently control motor speed, significantly reducing energy consumption (often 40%+) compared to running motors unregulated, at full speed

Cost savings and fast return on investment (ROI): VFDs lower energy bills, reduce maintenance, and improve process control, with a typical ROI of 6-12 months

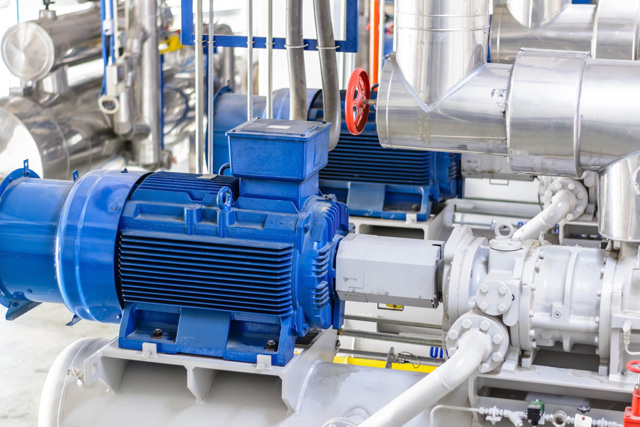

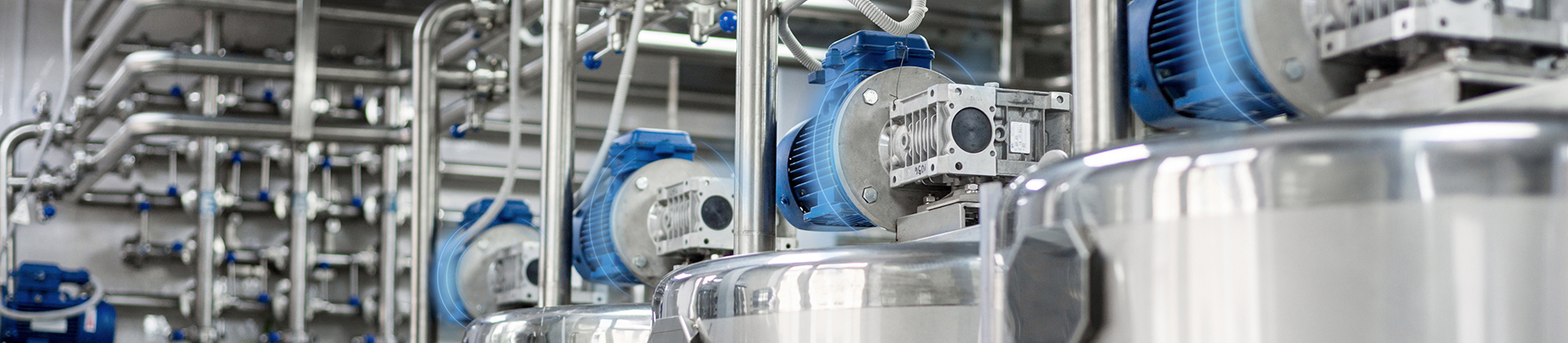

Versatile applications: VFDs and power converters optimize diverse applications, including fans, pumps, conveyors, cranes, marine propulsion, hydrogen electrolysis, and renewable energy systems

Beyond energy savings: VFDs offer benefits beyond energy savings, such as improved performance, enhanced process control, longer equipment life, and reduced emissions

Danfoss expertise: Danfoss specializes in VFDs to suit any motor type, offering a wide range of solutions, and global support for optimizing motor performance

What’s the difference between a VFD controller, an AC drive, and a variable speed drive (VSD)?

All these names refer to the same device. VFDs are also known by various other names such as adjustable speed drives, adjustable frequency drives or AFDs, variable frequency drives, variable voltage variable frequency drives, frequency converters, VFD inverters, and power converters.

You may be surprised

Did you know that:

- Emerging economies are driving the increase in energy consumption?

- 20% of the world’s energy consumption is electrical energy

- More than 50% of electrical energy is used by electrical motors

- 75% of VFDs are used to control pumps, fans and compressors

- Global electrical energy consumption could be reduced by 10% if VFDs were used in every suitable application

Variable frequency drives (VFDs) are largely invisible, hidden in basements and electrical rooms, but nevertheless they play a major and very necessary role in modern, everyday life, by making the world and our way of living more sustainable.

How does a VFD work to optimize electric motors?

The VFD sits between the electrical supply and the motor load. It controls the electrical motor speed by changing the frequency and voltage supplied to the motor. Power from the electrical supply goes into the VFD, which then regulates the power that is fed to the motor. The result? Instant energy savings.

Variable frequency drive FAQ

What’s special about drives from Danfoss?

The difference between Danfoss and other drive manufacturers is that Danfoss is a global market leader in VFDs, specializing purely in drives. Our focus is sharp on building the perfect VFD for your need and we offer millions of variants. The wide range of VFD variants is designed to suit any need for AC electric motor control, from sophisticated premium drives with integrated condition monitoring intelligence, to simple soft starters for basic protection. Drives from Danfoss optimize electric motor systems running any typical motor type, such as:

- Induction motors (IM)

- Permanent-magnet (PM) motors

- High-efficiency synchronous reluctance motors (SynRM)

What does it mean to think ‘beyond the bundle’?

Danfoss offers you the freedom to combine any motor and drive then optimize it for ultimate performance. You’re not restricted by supplier-defined drive-motor bundles. Many factors beyond efficiency class influence the best choice of VFD-motor combination. These factors include logistics, availability, and importantly, return on investment.

We offer you the best possible components and full flexibility so you can fine tune system performance to suit your application exactly. An important aspect of this flexibility is the ability to use your drives with all typical motor technologies, since drives from Danfoss are designed for full compatibility. This enables significant savings in spare part inventories and in retrofit situations. The same VFD can serve many different motors during a system lifetime.

When choosing a VFD supplier, it’s wise to consider the following factors, all of which influence total cost of operation: