Powerful performance in extreme conditions

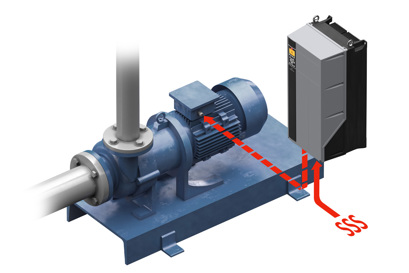

With one of the best power/size ratios, VACON® NXP Liquid Cooled drives are ideal for applications where space is at a premium or air cooling is difficult. Heavy industries with harsh operating conditions, such as in marine, offshore and mining environments benefit from the drive’s compact design and robust reliability.

Liquid-cooled AC drives can be used in many combinations, from a single dedicated frequency converter to large-scale common DC bus systems. Packed with features, these fully standardized drives maximize the utilization of space while minimizing overall lifecycle costs.

As a high degree of protection (IP54 or higher) can easily be achieved with these drives, they can be installed almost anywhere in a plant or on a vessel. This eliminates the load on air-conditioning systems in electrical rooms reducing costs and installation time, and makes them ideal for retrofitting.

Servicing is fast and easy. Features such as safe torque off (STO) and safe stop 1 (SS1) improve safety, and conformal coated circuit boards enhance reliability.

NXA, NXN, NXB and NXI configurations

Active Front-end (NXA), Non-regenerative Front-end (NXN), Brake Chopper (NXB) and Inverter (NXI) configurations are available. For more information about these configurations please refer to the VACON® NXP Common DC Bus selection guide.

Discontinued enclosure sizes

Enclosure sizes CH3 and CH4 have reached the Limited phase of their lifecycle and were discontinued in 2021. In this phase, Danfoss offers assistance using services such as DrivePro® Spare Parts, DrivePro® Retrofit, and in some cases, DrivePro® Preventive Maintenance.

Power range

- 3 x 400-500 V...132-4100 kW

- 3 x 525-690 V...110-5300 kW

Features and benefits

-

Floor space requirements and infrastructure needs are reduced as the compact design needs no air ducts

-

Investment savings as no large air-conditioning systems are needed due to minimal dissipation of heat loss to the air

-

Fulfills all relevant international standards and global requirements including marine, safety, EMC and harmonics approvals

-

Virtually silent operation as large cooling fans are not needed

Order VACON® NXP literature

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Case story | Abeking and Rasmussen WSV | English | Multiple | 03 May, 2023 | 4.5 MB | |

| Case story | Baltika Icebreaker | English | Multiple | 15 Mar, 2023 | 1.4 MB | |

| Case story | Caledonian Maritime Assets Limited CMAL | English | Multiple | 16 Mar, 2023 | 2.9 MB | |

| Brochure | Chemicals | English | Multiple | 22 Nov, 2021 | 10.5 MB | |

| Brochure | Chemicals - US English | English | United States | 22 Nov, 2021 | 9.7 MB | |

| Case story | Cogeis TBM - Full case | English | Multiple | 09 Aug, 2022 | 6.9 MB | |

| Case story | Cogeis TBM - Short case | English | Multiple | 09 Aug, 2022 | 3.4 MB | |

| Brochure | DrivePro® Services Overview | English | Multiple | 03 Feb, 2025 | 26.8 MB | |

| Brochure | DrivePro® Services Overview - US English | English | United States | 03 Feb, 2025 | 26.6 MB | |

| Case story | Electrosteel Castings Ltd | English | Multiple | 03 May, 2023 | 1.7 MB | |

| Application guide | Encoder-less Safety using DOLD Module | English | Multiple | 15 Apr, 2017 | 5.9 MB | |

| Brochure | Engineering - Chemical and Pharma | English | Multiple | 17 May, 2022 | 37.7 MB | |

| Case story | IJ Ferries | English | Multiple | 16 Mar, 2023 | 4.0 MB | |

| Case story | Jacket lift systems | English | Multiple | 03 May, 2023 | 6.1 MB | |

| Case story | LANXESS - Full case | English | Multiple | 03 May, 2023 | 5.6 MB | |

| Case story | Maximum Power for excavating uphill tunnels | English | Multiple | 24 Aug, 2023 | 6.9 MB | |

| Brochure | Mining and mineral processing | English | Multiple | 12 Nov, 2021 | 44.2 MB | |

| Case story | MS Goblin hybrid | English | Multiple | 16 Mar, 2023 | 6.6 MB | |

| Case story | Nadorias Hybrid Ship | English | Multiple | 16 Mar, 2023 | 4.2 MB | |

| Case story | Northern Leader | English | Multiple | 17 Mar, 2023 | 931.6 KB | |

| Case story | Northern Leader US 2017 - US English | English | United States | 03 May, 2023 | 1.9 MB | |

| Case story | Oil Pumping Fujairah | English | Multiple | 03 May, 2023 | 958.0 KB | |

| Brochure | Product Overview | English | Multiple | 09 May, 2025 | 12.6 MB | |

| Case story | STX | English | Multiple | 22 Mar, 2023 | 2.3 MB | |

| Case story | Telstar | English | Multiple | 17 Mar, 2023 | 5.0 MB | |

| Application guide | VACON Condition-based Monitoring | English | Multiple | 23 Feb, 2023 | 1.2 MB | |

| Fact sheet | VACON NXP drive anti-sway functionality | English | Multiple | 27 Feb, 2023 | 569.0 KB | |

| Fact sheet | VACON NXP drive anti-sway functionality - US English | English | United States | 27 Feb, 2023 | 595.3 KB | |

| Fact sheet | VACON NXP Liquid Cooled non regenerative front-end | English | Multiple | 07 Aug, 2023 | 316.0 KB | |

| Brochure | VACON NXP Liquid Cooled Selection Guide | English | Multiple | 12 Jun, 2023 | 24.0 MB | |

| Brochure | VACON NXP Liquid Cooled Selection Guide - US English | English | United States | 19 Nov, 2021 | 18.3 MB | |

| Operating guide | VACON-NX-Line-Voltage-Measurement-OG | English | Multiple | 27 Mar, 2023 | 13.0 MB | |

| Design guide | VACON® Hybridization Design Guide | English | Multiple | 14 Jan, 2017 | 3.8 MB | |

| Application guide | VACON® NX All in One Application Guide | English | Multiple | 03 Jun, 2025 | 7.5 MB | |

| Application guide | VACON® NX BCU ABFIFF01V126 Appl. Man | English | Multiple | 28 Nov, 2023 | 745.3 KB | |

| Operating guide | VACON® NX Liquid Cooled Drives User Manual | English | Multiple | 10 Dec, 2025 | 22.3 MB | |

| Application guide | VACON® NX Marine APFIFF09V242 Appl. Man | English | Multiple | 28 Nov, 2023 | 3.3 MB | |

| Application guide | VACON® NX Sys Interf. APFIFF10V244 ApplM | English | Multiple | 15 Apr, 2019 | 808.0 KB | |

| Operating guide | VACON® NXP Advanced Safety Options | English | Multiple | 12 Sep, 2024 | 14.1 MB | |

| Application guide | VACON® NXP CraneContr APFIFF20v099 ApplM | English | Multiple | 15 Jan, 2021 | 2.7 MB | |

| Application guide | VACON® NXP Funct. Safety App.G for Lifts | English | Multiple | 15 Nov, 2019 | 1.4 MB | |

| Application guide | VACON® NXP HighSpeed APFIFF41V323 Manual | English | Multiple | 15 Jan, 2021 | 2.1 MB | |

| Application guide | VACON® NXP LineSynchII APFIFF44V120 AppM | English | Multiple | 15 Jun, 2021 | 1.9 MB | |

| Application guide | VACON® NXP Shaft Sync APFIFF11 Appl Man | English | Multiple | 15 Dec, 2015 | 1.1 MB | |

| Application guide | VACON® NXP SIA II APFIFF40V111 ApplM | English | Multiple | 28 Nov, 2023 | 3.0 MB | |

| Application guide | VACON® NXS-P FireM.PID ASFIFF11V210 AppM | English | Multiple | 15 Dec, 2015 | 229.5 KB | |

| Case story | Viking River Cruises | English | Multiple | 17 Mar, 2023 | 6.4 MB | |

| Case story | Waterschap Zuiderzeeland | English | Multiple | 22 Mar, 2023 | 7.2 MB | |

| White paper | Why supply land-based power | English | Multiple | 28 Feb, 2023 | 10.6 MB |

3D models and drawings

| Type | Name | Language | Updated | Download | File type |

|---|---|---|---|---|---|

| Dimensional drawing | MCAD VACON HXL 040 IP00 P | 17 Dec, 2025 | 1.1 MB | ||

| Dimensional drawing | MCAD VACON HXL 040 IP00 S | 17 Dec, 2025 | 988.6 KB | ||

| Dimensional drawing | MCAD VACON HXL 040 P PI diagram | 17 Dec, 2025 | 1.2 MB | ||

| Dimensional drawing | MCAD VACON HXL 040 S PI diagram | 17 Dec, 2025 | 1.2 MB | ||

| Dimensional drawing | MCAD VACON HXL 120 IP00 P | 17 Dec, 2025 | 2.3 MB | .dwg | |

| Dimensional drawing | MCAD VACON HXL 120 IP00 P | 17 Dec, 2025 | 999.6 KB | ||

| Dimensional drawing | MCAD VACON HXL 120 IP00 S | 17 Dec, 2025 | 945.2 KB | ||

| Dimensional drawing | MCAD VACON HXL 120 P PI diagram | 17 Dec, 2025 | 495.2 KB | ||

| Dimensional drawing | MCAD VACON HXL 120 S PI diagram | 17 Dec, 2025 | 491.8 KB | ||

| Dimensional drawing | MCAD VACON HXL 300 IP00 P | 17 Dec, 2025 | 1.0 MB | ||

| Dimensional drawing | MCAD VACON HXL 300 IP00 P | 17 Dec, 2025 | 4.0 MB | .dwg | |

| Dimensional drawing | MCAD VACON HXL 300 IP00 S | 17 Dec, 2025 | 1.0 MB | ||

| Dimensional drawing | MCAD VACON HXL 300 IP00 S | 17 Dec, 2025 | 4.1 MB | .dwg | |

| Dimensional drawing | MCAD VACON HXL 300 P PI diagram | 17 Dec, 2025 | 100.2 KB | .dwg | |

| Dimensional drawing | MCAD VACON HXL 300 P PI diagram | 17 Dec, 2025 | 100.2 KB | .dwg | |

| Dimensional drawing | MCAD VACON HXL 300 S PI diagram | 17 Dec, 2025 | 1.2 MB | ||

| Dimensional drawing | MCAD VACON HXL 300 S PI diagram | 17 Dec, 2025 | 101.0 KB | .dwg | |

| Dimensional drawing | MCAD VACON HXL R 040 IP54 P | 17 Dec, 2025 | 1.2 MB | ||

| Dimensional drawing | MCAD VACON HXL R 040 IP54 S | 17 Dec, 2025 | 1.0 MB | ||

| Dimensional drawing | MCAD VACON HXL R 120 IP54 P | 17 Dec, 2025 | 1.7 MB | .dwg | |

| Dimensional drawing | MCAD VACON HXL R 120 IP54 P | 17 Dec, 2025 | 997.0 KB | ||

| Dimensional drawing | MCAD VACON HXL R 120 IP54 S | 17 Dec, 2025 | 1.0 MB | ||

| Dimensional drawing | MCAD VACON HXL R 120 IP54 S | 17 Dec, 2025 | 1.7 MB | .dwg | |

| Dimensional drawing | MCAD VACON HXL R 300 IP54 P | 17 Dec, 2025 | 2.6 MB | .dwg | |

| Dimensional drawing | MCAD VACON HXL R 300 IP54 P | 17 Dec, 2025 | 1.0 MB | ||

| Dimensional drawing | MCAD VACON HXL R 300 IP54 S | 17 Dec, 2025 | 1.0 MB | ||

| Dimensional drawing | MCAD VACON HXL V 040 IP54 P | 17 Dec, 2025 | 1.1 MB | ||

| Dimensional drawing | MCAD VACON HXL V 040 IP54 S | 17 Dec, 2025 | 974.8 KB | ||

| Dimensional drawing | MCAD VACON HXL V 120 IP54 P | 17 Dec, 2025 | 1.8 MB | .dwg | |

| Dimensional drawing | MCAD VACON HXL V 120 IP54 P | 17 Dec, 2025 | 997.1 KB | ||

| Dimensional drawing | MCAD VACON HXL V 120 IP54 S | 17 Dec, 2025 | 1.8 MB | .dwg | |

| Dimensional drawing | MCAD VACON HXL V 120 IP54 S | 17 Dec, 2025 | 1.0 MB | ||

| Dimensional drawing | MCAD VACON HXM 120 IP00 P | 17 Dec, 2025 | 3.1 MB | .dwg | |

| Dimensional drawing | MCAD VACON HXM 120 IP00 P | 17 Dec, 2025 | 973.4 KB | ||

| Dimensional drawing | MCAD VACON HXM 120 IP00 S | 17 Dec, 2025 | 1.0 MB | ||

| Dimensional drawing | MCAD VACON HXM 120 IP00 S | 17 Dec, 2025 | 3.2 MB | .dwg | |

| Dimensional drawing | MCAD VACON HXM 120 P PI diagram | 17 Dec, 2025 | 521.2 KB | ||

| Dimensional drawing | MCAD VACON HXM 120 S PI diagram | 17 Dec, 2025 | 513.8 KB | ||

| Dimensional drawing | MCAD VACON HXM 300 IP00 P | 17 Dec, 2025 | 1.0 MB | ||

| Dimensional drawing | MCAD VACON HXM 300 IP00 S | 17 Dec, 2025 | 1.0 MB | ||

| Dimensional drawing | MCAD VACON HXM 300 P PI diagram | 17 Dec, 2025 | 1.2 MB | ||

| Dimensional drawing | MCAD VACON HXM 300 S PI diagram | 17 Dec, 2025 | 1.3 MB | ||

| Dimensional drawing | MCAD VACON HXM R 120 IP54 P | 17 Dec, 2025 | 1.0 MB | ||

| Dimensional drawing | MCAD VACON HXM R 120 IP54 P | 17 Dec, 2025 | 2.3 MB | .dwg | |

| Dimensional drawing | MCAD VACON HXM R 120 IP54 S | 17 Dec, 2025 | 1.1 MB | ||

| Dimensional drawing | MCAD VACON HXM R 120 IP54 S | 17 Dec, 2025 | 2.3 MB | .dwg | |

| Dimensional drawing | MCAD VACON HXM R 300 IP54 P | 17 Dec, 2025 | 1.0 MB | ||

| Dimensional drawing | MCAD VACON HXM R 300 IP54 S | 17 Dec, 2025 | 1.0 MB | ||

| Dimensional drawing | MCAD VACON HXM V 120 IP54 P | 17 Dec, 2025 | 1.0 MB | ||

| Dimensional drawing | MCAD VACON HXM V 120 IP54 P | 17 Dec, 2025 | 2.4 MB | .dwg | |

| Dimensional drawing | MCAD VACON HXM V 120 IP54 S | 17 Dec, 2025 | 2.4 MB | .dwg | |

| Dimensional drawing | MCAD VACON HXM V 120 IP54 S | 17 Dec, 2025 | 1.1 MB | ||

| Dimensional drawing | MCAD VACON NXP Ch3 IP00 | 17 Dec, 2025 | 266.5 KB | .dwg | |

| Dimensional drawing | MCAD VACON NXP Ch3 IP00 | 17 Dec, 2025 | 40.8 KB | ||

| Dimensional drawing | MCAD VACON NXP Ch4 IP00 | 17 Dec, 2025 | 56.2 KB | ||

| Dimensional drawing | MCAD VACON NXP Ch4 IP00 | 17 Dec, 2025 | 276.6 KB | .dwg | |

| Dimensional drawing | MCAD VACON NXP Ch4 IP00 INU | 17 Dec, 2025 | 274.0 KB | .dwg | |

| Dimensional drawing | MCAD VACON NXP Ch4 IP00 INU | 17 Dec, 2025 | 54.8 KB | ||

| Dimensional drawing | MCAD VACON NXP Ch5 IP00 | 17 Dec, 2025 | 1.5 MB | .dwg | |

| Dimensional drawing | MCAD VACON NXP Ch5 IP00 | 17 Dec, 2025 | 168.5 KB | ||

| Dimensional drawing | MCAD VACON NXP Ch5 IP00 INU | 17 Dec, 2025 | 168.7 KB | ||

| Dimensional drawing | MCAD VACON NXP Ch5 IP00 INU | 17 Dec, 2025 | 1.4 MB | .dwg | |

| Dimensional drawing | MCAD VACON NXP Ch60 IP00 | 17 Dec, 2025 | 1.0 MB | .dwg | |

| Dimensional drawing | MCAD VACON NXP Ch60 IP00 | 17 Dec, 2025 | 300.9 KB | ||

| Dimensional drawing | MCAD VACON NXP Ch61 IP00 | 17 Dec, 2025 | 6.2 MB | .dwg | |

| Dimensional drawing | MCAD VACON NXP Ch61 IP00 | 17 Dec, 2025 | 238.5 KB | ||

| Dimensional drawing | MCAD VACON NXP Ch61 IP00 INU | 17 Dec, 2025 | 234.2 KB | ||

| Dimensional drawing | MCAD VACON NXP Ch61 IP00 INU | 17 Dec, 2025 | 6.3 MB | .dwg | |

| Dimensional drawing | MCAD VACON NXP Ch62 IP00 INU | 17 Dec, 2025 | 8.1 MB | .dwg | |

| Dimensional drawing | MCAD VACON NXP Ch62 IP00 INU | 17 Dec, 2025 | 247.2 KB | ||

| Dimensional drawing | MCAD VACON NXP Ch63 IP00 | 17 Dec, 2025 | 15.3 MB | .dwg | |

| Dimensional drawing | MCAD VACON NXP Ch63 IP00 | 17 Dec, 2025 | 360.7 KB | ||

| Dimensional drawing | MCAD VACON NXP Ch63 IP00 INU | 17 Dec, 2025 | 30.6 MB | .dwg | |

| Dimensional drawing | MCAD VACON NXP Ch63 IP00 INU | 17 Dec, 2025 | 371.1 KB | ||

| Dimensional drawing | MCAD VACON NXP Ch64 IP00 INU | 17 Dec, 2025 | 417.3 KB | ||

| Dimensional drawing | MCAD VACON NXP Ch64 IP00 INU | 17 Dec, 2025 | 25.8 MB | .dwg | |

| Dimensional drawing | MCAD VACON NXP Ch64 IP00 INU | 17 Dec, 2025 | 2.7 MB | .stp | |

| Dimensional drawing | MCAD VACON NXP Ch72 IP00 12p | 17 Dec, 2025 | 990.5 KB | ||

| Dimensional drawing | MCAD VACON NXP Ch72 IP00 12p | 17 Dec, 2025 | 5.3 MB | .dwg | |

| Dimensional drawing | MCAD VACON NXP Ch72 IP00 6p | 17 Dec, 2025 | 5.4 MB | .dwg | |

| Dimensional drawing | MCAD VACON NXP Ch72 IP00 6p | 17 Dec, 2025 | 1.0 MB | ||

| Dimensional drawing | MCAD VACON NXP Ch72 IP00 6p brkchop | 17 Dec, 2025 | 1.0 MB | ||

| Dimensional drawing | MCAD VACON NXP Ch72 IP00 6p brkchop | 17 Dec, 2025 | 5.4 MB | .dwg | |

| Dimensional drawing | MCAD VACON NXP Ch74 IP00 12p | 17 Dec, 2025 | 33.9 MB | .stp | |

| Dimensional drawing | MCAD VACON NXP Ch74 IP00 12p | 17 Dec, 2025 | 2.2 MB | ||

| Dimensional drawing | MCAD VACON NXP Ch74 IP00 12p | 17 Dec, 2025 | 13.9 MB | .dwg | |

| Dimensional drawing | MCAD VACON NXP Ch74 IP00 12p brk chop | 17 Dec, 2025 | 2.1 MB | ||

| Dimensional drawing | MCAD VACON NXP Ch74 IP00 12p brk chop | 17 Dec, 2025 | 13.6 MB | .dwg | |

| Dimensional drawing | MCAD VACON NXP Ch74 IP00 6p | 17 Dec, 2025 | 33.8 MB | .stp | |

| Dimensional drawing | MCAD VACON NXP Ch74 IP00 6p | 17 Dec, 2025 | 2.1 MB | ||

| Dimensional drawing | MCAD VACON NXP Ch74 IP00 6p | 17 Dec, 2025 | 13.9 MB | .dwg | |

| Dimensional drawing | MCAD VACON NXP Ch74 IP00 6p brk chop | 17 Dec, 2025 | 13.8 MB | .dwg | |

| Dimensional drawing | MCAD VACON NXP Ch74 IP00 6p brk chop | 17 Dec, 2025 | 2.1 MB | ||

| Dimensional drawing | MCAD VACON NXW CH74 IP54 Control box | 17 Dec, 2025 | 7.0 MB | .stp | |

| Eplan drawing | NXB_0031 5 A0T08WS | 17 Dec, 2025 | 553.6 KB | .zip | |

| Eplan drawing | NXB_0061 5 A0T08WS | 17 Dec, 2025 | 553.6 KB | .zip | |

| Eplan drawing | NXB_0087 5 A0T08WS | 17 Dec, 2025 | 495.5 KB | .zip | |

| Eplan drawing | NXB_0105 5 A0T08WS | 17 Dec, 2025 | 495.5 KB | .zip | |

| Eplan drawing | NXB_0140 5 A0T08WS | 17 Dec, 2025 | 495.5 KB | .zip | |

| Eplan drawing | NXB_0168 5 A0T08WS | 17 Dec, 2025 | 336.4 KB | .zip | |

| Eplan drawing | NXB_0170 6 A0T08WF | 17 Dec, 2025 | 416.6 KB | .zip | |

| Eplan drawing | NXB_0205 5 A0T08WS | 17 Dec, 2025 | 336.4 KB | .zip | |

| Eplan drawing | NXB_0208 6 A0T08WF | 17 Dec, 2025 | 416.6 KB | .zip | |

| Eplan drawing | NXB_0261 5 A0T08WS | 17 Dec, 2025 | 336.4 KB | .zip | |

| Eplan drawing | NXB_0261 6 A0T08WF | 17 Dec, 2025 | 416.6 KB | .zip | |

| Eplan drawing | NXB_0300 5 A0T08WF | 17 Dec, 2025 | 416.6 KB | .zip | |

| Eplan drawing | NXB_0325 6 A0T08WF | 17 Dec, 2025 | 1.4 MB | .zip | |

| Eplan drawing | NXB_0385 5 A0T08WF | 17 Dec, 2025 | 416.6 KB | .zip | |

| Eplan drawing | NXB_0385 6 A0T08WF | 17 Dec, 2025 | 1.4 MB | .zip | |

| Eplan drawing | NXB_0416 6 A0T08WF | 17 Dec, 2025 | 1.4 MB | .zip | |

| Eplan drawing | NXB_0460 5 A0T08WF | 17 Dec, 2025 | 1.4 MB | .zip | |

| Eplan drawing | NXB_0460 6 A0T08WF | 17 Dec, 2025 | 1.4 MB | .zip | |

| Eplan drawing | NXB_0502 6 A0T08WF | 17 Dec, 2025 | 1.4 MB | .zip | |

| Eplan drawing | NXB_0520 5 A0T08WF | 17 Dec, 2025 | 1.4 MB | .zip | |

| Eplan drawing | NXB_0590 5 A0T08WF | 17 Dec, 2025 | 1.4 MB | .zip | |

| Eplan drawing | NXB_0650 5 A0T08WF | 17 Dec, 2025 | 1.4 MB | .zip | |

| Eplan drawing | NXB_0730 5 A0T08WF | 17 Dec, 2025 | 1.4 MB | .zip | |

| Eplan drawing | NXP_0016 5 A0N1SWS | 17 Dec, 2025 | 554.1 KB | .zip | |

| Eplan drawing | NXP_0016 5 A0T1IWS | 17 Dec, 2025 | 553.9 KB | .zip | |

| Eplan drawing | NXP_0022 5 A0N1SWS | 17 Dec, 2025 | 554.0 KB | .zip | |

| Eplan drawing | NXP_0022 5 A0T1IWS | 17 Dec, 2025 | 553.8 KB | .zip | |

| Eplan drawing | NXP_0031 5 A0N1SWS | 17 Dec, 2025 | 554.0 KB | .zip | |

| Eplan drawing | NXP_0031 5 A0T1IWS | 17 Dec, 2025 | 553.8 KB | .zip | |

| Eplan drawing | NXP_0038 5 A0N1SWS | 17 Dec, 2025 | 554.0 KB | .zip | |

| Eplan drawing | NXP_0038 5 A0T1IWS | 17 Dec, 2025 | 553.9 KB | .zip | |

| Eplan drawing | NXP_0045 5 A0N1SWS | 17 Dec, 2025 | 554.0 KB | .zip | |

| Eplan drawing | NXP_0045 5 A0T1IWS | 17 Dec, 2025 | 553.8 KB | .zip | |

| Eplan drawing | NXP_0061 5 A0N1SWS | 17 Dec, 2025 | 554.0 KB | .zip | |

| Eplan drawing | NXP_0061 5 A0T1IWS | 17 Dec, 2025 | 553.9 KB | .zip | |

| Eplan drawing | NXP_0072 5 A0N0SWS | 17 Dec, 2025 | 495.8 KB | .zip | |

| Eplan drawing | NXP_0072 5 A0T0IWS | 17 Dec, 2025 | 495.6 KB | .zip | |

| Eplan drawing | NXP_0087 5 A0N0SWS | 17 Dec, 2025 | 495.8 KB | .zip | |

| Eplan drawing | NXP_0087 5 A0T0IWS | 17 Dec, 2025 | 495.6 KB | .zip | |

| Eplan drawing | NXP_0105 5 A0N0SWS | 17 Dec, 2025 | 495.8 KB | .zip | |

| Eplan drawing | NXP_0105 5 A0T0IWS | 17 Dec, 2025 | 495.6 KB | .zip | |

| Eplan drawing | NXP_0140 5 A0N0SWS | 17 Dec, 2025 | 495.8 KB | .zip | |

| Eplan drawing | NXP_0140 5 A0T0IWS | 17 Dec, 2025 | 495.6 KB | .zip | |

| Eplan drawing | NXP_0168 5 A0N0SWS | 17 Dec, 2025 | 336.5 KB | .zip | |

| Eplan drawing | NXP_0168 5 A0T0IWS | 17 Dec, 2025 | 336.6 KB | .zip | |

| Eplan drawing | NXP_0170 6 A0T0IWF | 17 Dec, 2025 | 417.0 KB | .zip | |

| Eplan drawing | NXP_0170 6 A0T0SWF | 11 Feb, 2026 | 448.6 KB | .zip | |

| Eplan drawing | NXP_0205 5 A0N0SWS | 17 Dec, 2025 | 336.5 KB | .zip | |

| Eplan drawing | NXP_0205 5 A0T0IWS | 17 Dec, 2025 | 336.6 KB | .zip | |

| Eplan drawing | NXP_0208 6 A0T0IWF | 17 Dec, 2025 | 417.0 KB | .zip | |

| Eplan drawing | NXP_0208 6 A0T0SWF | 18 Feb, 2026 | 448.7 KB | .zip | |

| Eplan drawing | NXP_0261 5 A0N0SWS | 17 Dec, 2025 | 336.5 KB | .zip | |

| Eplan drawing | NXP_0261 5 A0T0IWS | 17 Dec, 2025 | 336.6 KB | .zip | |

| Eplan drawing | NXP_0261 6 A0T0IWF | 17 Dec, 2025 | 417.0 KB | .zip | |

| Eplan drawing | NXP_0261 6 A0T0SWF | 17 Dec, 2025 | 448.5 KB | .zip | |

| Eplan drawing | NXP_0300 5 A0N0SWF | 17 Dec, 2025 | 448.5 KB | .zip | |

| Eplan drawing | NXP_0300 5 A0T0IWF | 17 Dec, 2025 | 416.9 KB | .zip | |

| Eplan drawing | NXP_0325 6 A0T0IWF | 17 Dec, 2025 | 1.4 MB | .zip | |

| Eplan drawing | NXP_0325 6 A0T0SWF | 17 Dec, 2025 | 1.4 MB | .zip | |

| Eplan drawing | NXP_0325 6 A0T0TWF | 17 Dec, 2025 | 1.2 MB | .zip | |

| Eplan drawing | NXP_0385 5 A0N0SWF | 17 Dec, 2025 | 448.5 KB | .zip | |

| Eplan drawing | NXP_0385 5 A0T0IWF | 17 Dec, 2025 | 417.0 KB | .zip | |

| Eplan drawing | NXP_0385 6 A0T0IWF | 17 Dec, 2025 | 1.4 MB | .zip | |

| Eplan drawing | NXP_0385 6 A0T0SWF | 17 Dec, 2025 | 1.4 MB | .zip | |

| Eplan drawing | NXP_0385 6 A0T0TWF | 17 Dec, 2025 | 1.2 MB | .zip | |

| Eplan drawing | NXP_0416 6 A0T0IWF | 17 Dec, 2025 | 1.4 MB | .zip | |

| Eplan drawing | NXP_0416 6 A0T0SWF | 17 Dec, 2025 | 1.4 MB | .zip | |

| Eplan drawing | NXP_0416 6 A0T0TWF | 17 Dec, 2025 | 1.2 MB | .zip | |

| Eplan drawing | NXP_0460 5 A0N0SWF | 17 Dec, 2025 | 1.4 MB | .zip | |

| Eplan drawing | NXP_0460 5 A0N0TWF | 17 Dec, 2025 | 1.2 MB | .zip | |

| Eplan drawing | NXP_0460 5 A0T0IWF | 17 Dec, 2025 | 1.4 MB | .zip | |

| Eplan drawing | NXP_0460 6 A0T0IWF | 17 Dec, 2025 | 1.4 MB | .zip | |

| Eplan drawing | NXP_0460 6 A0T0SWF | 17 Dec, 2025 | 1.4 MB | .zip | |

| Eplan drawing | NXP_0460 6 A0T0TWF | 17 Dec, 2025 | 1.2 MB | .zip | |

| Eplan drawing | NXP_0502 6 A0T0IWF | 17 Dec, 2025 | 1.4 MB | .zip | |

| Eplan drawing | NXP_0502 6 A0T0SWF | 17 Dec, 2025 | 1.4 MB | .zip | |

| Eplan drawing | NXP_0502 6 A0T0TWF | 17 Dec, 2025 | 1.2 MB | .zip | |

| Eplan drawing | NXP_0520 5 A0N0SWF | 17 Dec, 2025 | 1.4 MB | .zip | |

| Eplan drawing | NXP_0520 5 A0N0TWF | 17 Dec, 2025 | 1.2 MB | .zip | |

| Eplan drawing | NXP_0520 5 A0T0IWF | 17 Dec, 2025 | 1.4 MB | .zip | |

| Eplan drawing | NXP_0590 5 A0N0SWF | 17 Dec, 2025 | 1.4 MB | .zip | |

| Eplan drawing | NXP_0590 5 A0N0TWF | 17 Dec, 2025 | 1.2 MB | .zip | |

| Eplan drawing | NXP_0590 5 A0T0IWF | 17 Dec, 2025 | 1.4 MB | .zip | |

| Eplan drawing | NXP_0590 6 A0T0IWF | 17 Dec, 2025 | 3.2 MB | .zip | |

| Eplan drawing | NXP_0590 6 A0T0SWF | 17 Dec, 2025 | 953.7 KB | .zip | |

| Eplan drawing | NXP_0650 5 A0N0SWF | 17 Dec, 2025 | 1.4 MB | .zip | |

| Eplan drawing | NXP_0650 5 A0N0TWF | 17 Dec, 2025 | 1.2 MB | .zip | |

| Eplan drawing | NXP_0650 5 A0T0IWF | 17 Dec, 2025 | 1.4 MB | .zip | |

| Eplan drawing | NXP_0650 6 A0T0IWF | 17 Dec, 2025 | 3.2 MB | .zip | |

| Eplan drawing | NXP_0650 6 A0T0SWF | 17 Dec, 2025 | 953.7 KB | .zip | |

| Eplan drawing | NXP_0730 5 A0N0SWF | 17 Dec, 2025 | 1.4 MB | .zip | |

| Eplan drawing | NXP_0730 5 A0N0TWF | 17 Dec, 2025 | 1.2 MB | .zip | |

| Eplan drawing | NXP_0730 5 A0T0IWF | 17 Dec, 2025 | 1.4 MB | .zip | |

| Eplan drawing | NXP_0750 6 A0T0IWF | 17 Dec, 2025 | 3.2 MB | .zip | |

| Eplan drawing | NXP_0750 6 A0T0SWF | 17 Dec, 2025 | 953.7 KB | .zip | |

| Eplan drawing | NXP_0820 5 A0N0SWF | 17 Dec, 2025 | 953.7 KB | .zip | |

| Eplan drawing | NXP_0820 5 A0T0IWF | 17 Dec, 2025 | 3.2 MB | .zip | |

| Eplan drawing | NXP_0820 6 A0T0IWF | 17 Dec, 2025 | 924.5 KB | .zip | |

| Eplan drawing | NXP_0820 6 A0T0SWF | 17 Dec, 2025 | 1.7 MB | .zip | |

| Eplan drawing | NXP_0820 6 A0T0TWF | 17 Dec, 2025 | 1.5 MB | .zip | |

| Eplan drawing | NXP_0920 5 A0N0SWF | 17 Dec, 2025 | 953.7 KB | .zip | |

| Eplan drawing | NXP_0920 5 A0T0IWF | 17 Dec, 2025 | 3.2 MB | .zip | |

| Eplan drawing | NXP_0920 6 A0T0IWF | 17 Dec, 2025 | 924.5 KB | .zip | |

| Eplan drawing | NXP_0920 6 A0T0SWF | 17 Dec, 2025 | 1.7 MB | .zip | |

| Eplan drawing | NXP_0920 6 A0T0TWF | 17 Dec, 2025 | 1.5 MB | .zip | |

| Eplan drawing | NXP_1030 5 A0N0SWF | 17 Dec, 2025 | 953.7 KB | .zip | |

| Eplan drawing | NXP_1030 5 A0T0IWF | 17 Dec, 2025 | 3.2 MB | .zip | |

| Eplan drawing | NXP_1030 6 A0T0IWF | 17 Dec, 2025 | 924.5 KB | .zip | |

| Eplan drawing | NXP_1030 6 A0T0SWF | 17 Dec, 2025 | 1.7 MB | .zip | |

| Eplan drawing | NXP_1030 6 A0T0TWF | 17 Dec, 2025 | 1.5 MB | .zip | |

| Eplan drawing | NXP_1150 5 A0N0SWF | 17 Dec, 2025 | 953.7 KB | .zip | |

| Eplan drawing | NXP_1150 5 A0T0IWF | 17 Dec, 2025 | 3.2 MB | .zip | |

| Eplan drawing | NXP_1180 6 A0T0IWF | 17 Dec, 2025 | 924.5 KB | .zip | |

| Eplan drawing | NXP_1180 6 A0T0SWF | 17 Dec, 2025 | 1.7 MB | .zip | |

| Eplan drawing | NXP_1180 6 A0T0TWF | 17 Dec, 2025 | 1.5 MB | .zip | |

| Eplan drawing | NXP_1300 6 A0T0IWF | 17 Dec, 2025 | 924.5 KB | .zip | |

| Eplan drawing | NXP_1300 6 A0T0SWF | 17 Dec, 2025 | 1.7 MB | .zip | |

| Eplan drawing | NXP_1300 6 A0T0TWF | 17 Dec, 2025 | 1.5 MB | .zip | |

| Eplan drawing | NXP_1370 5 A0N0SWF | 17 Dec, 2025 | 1.7 MB | .zip | |

| Eplan drawing | NXP_1370 5 A0N0TWF | 17 Dec, 2025 | 1.5 MB | .zip | |

| Eplan drawing | NXP_1370 5 A0T0IWF | 17 Dec, 2025 | 924.5 KB | .zip | |

| Eplan drawing | NXP_1500 6 A0T0IWF | 17 Dec, 2025 | 924.5 KB | .zip | |

| Eplan drawing | NXP_1500 6 A0T0SWF | 17 Dec, 2025 | 1.7 MB | .zip | |

| Eplan drawing | NXP_1500 6 A0T0TWF | 17 Dec, 2025 | 1.5 MB | .zip | |

| Eplan drawing | NXP_1640 5 A0N0SWF | 17 Dec, 2025 | 1.7 MB | .zip | |

| Eplan drawing | NXP_1640 5 A0N0TWF | 17 Dec, 2025 | 1.5 MB | .zip | |

| Eplan drawing | NXP_1640 5 A0T0IWF | 17 Dec, 2025 | 924.5 KB | .zip | |

| Eplan drawing | NXP_1700 6 A0T0IWF | 17 Dec, 2025 | 924.5 KB | .zip | |

| Eplan drawing | NXP_1700 6 A0T0SWF | 17 Dec, 2025 | 1.7 MB | .zip | |

| Eplan drawing | NXP_1700 6 A0T0TWF | 17 Dec, 2025 | 1.5 MB | .zip | |

| Eplan drawing | NXP_2060 5 A0N0SWF | 17 Dec, 2025 | 1.7 MB | .zip | |

| Eplan drawing | NXP_2060 5 A0N0TWF | 17 Dec, 2025 | 1.5 MB | .zip | |

| Eplan drawing | NXP_2060 5 A0T0IWF | 17 Dec, 2025 | 924.5 KB | .zip | |

| Eplan drawing | NXP_2300 5 A0N0SWF | 17 Dec, 2025 | 1.7 MB | .zip | |

| Eplan drawing | NXP_2300 5 A0T0IWF | 17 Dec, 2025 | 924.5 KB | .zip | |

| Eplan drawing | OPTA1_VACON_NX | 17 Dec, 2025 | 267.3 KB | .zip | |

| Eplan drawing | OPTA2_VACON_NX | 17 Dec, 2025 | 240.1 KB | .zip | |

| Eplan drawing | OPTA3_VACON_NX | 17 Dec, 2025 | 251.0 KB | .zip | |

| Eplan drawing | OPTA4_VACON_NX | 17 Dec, 2025 | 264.1 KB | .zip | |

| Eplan drawing | OPTA5_VACON_NX | 17 Dec, 2025 | 270.3 KB | .zip | |

| Eplan drawing | OPTA7_VACON_NX | 17 Dec, 2025 | 276.0 KB | .zip | |

| Eplan drawing | OPTA8_VACON_NX | 17 Dec, 2025 | 277.1 KB | .zip | |

| Eplan drawing | OPTA9_VACON_NX | 17 Dec, 2025 | 262.9 KB | .zip | |

| Eplan drawing | OPTAE_VACON_NX | 17 Dec, 2025 | 261.7 KB | .zip | |

| Eplan drawing | OPTAF_VACON_NX | 17 Dec, 2025 | 245.5 KB | .zip | |

| Eplan drawing | OPTAK_VACON_NX | 17 Dec, 2025 | 275.6 KB | .zip | |

| Eplan drawing | OPTAL_VACON_NX | 17 Dec, 2025 | 282.5 KB | .zip | |

| Eplan drawing | OPTAN_VACON_NX | 17 Dec, 2025 | 269.8 KB | .zip | |

| Eplan drawing | OPTB1_VACON_NX | 17 Dec, 2025 | 276.4 KB | .zip | |

| Eplan drawing | OPTB2_VACON_NX | 17 Dec, 2025 | 258.0 KB | .zip | |

| Eplan drawing | OPTB4_VACON_NX | 17 Dec, 2025 | 347.0 KB | .zip | |

| Eplan drawing | OPTB5_VACON_NX | 17 Dec, 2025 | 246.8 KB | .zip | |

| Eplan drawing | OPTB8_VACON_NX | 17 Dec, 2025 | 268.2 KB | .zip | |

| Eplan drawing | OPTB9_VACON_NX | 17 Dec, 2025 | 254.8 KB | .zip | |

| Eplan drawing | OPTBB_VACON_NX | 17 Dec, 2025 | 275.5 KB | .zip | |

| Eplan drawing | OPTBC_VACON_NX | 17 Dec, 2025 | 275.5 KB | .zip | |

| Eplan drawing | OPTBE_VACON_NX | 17 Dec, 2025 | 272.0 KB | .zip | |

| Eplan drawing | OPTBH_VACON_NX | 17 Dec, 2025 | 360.9 KB | .zip | |

| Eplan drawing | OPTC2_VACON_NX | 17 Dec, 2025 | 260.4 KB | .zip | |

| Eplan drawing | OPTC3_VACON_NX | 17 Dec, 2025 | 274.6 KB | .zip | |

| Eplan drawing | OPTC4_VACON_NX | 17 Dec, 2025 | 267.3 KB | .zip | |

| Eplan drawing | OPTC5_VACON_NX | 17 Dec, 2025 | 269.8 KB | .zip | |

| Eplan drawing | OPTC6_VACON_NX | 17 Dec, 2025 | 268.8 KB | .zip | |

| Eplan drawing | OPTC7_VACON_NX | 17 Dec, 2025 | 264.8 KB | .zip | |

| Eplan drawing | OPTC8_VACON_NX | 17 Dec, 2025 | 266.9 KB | .zip | |

| Eplan drawing | OPTCG_VACON_NX | 17 Dec, 2025 | 270.7 KB | .zip | |

| Eplan drawing | OPTCI_VACON_NX | 17 Dec, 2025 | 257.1 KB | .zip | |

| Eplan drawing | OPTCJ_VACON_NX | 17 Dec, 2025 | 267.5 KB | .zip | |

| Eplan drawing | OPTCP_VACON_NX | 17 Dec, 2025 | 266.7 KB | .zip | |

| Eplan drawing | OPTCQ_VACON_NX | 17 Dec, 2025 | 258.3 KB | .zip | |

| Eplan drawing | OPTD1_VACON_NX | 17 Dec, 2025 | 262.9 KB | .zip | |

| Eplan drawing | OPTD2_VACON_NX | 17 Dec, 2025 | 265.9 KB | .zip | |

| Eplan drawing | OPTD3_VACON_NX | 17 Dec, 2025 | 267.6 KB | .zip | |

| Eplan drawing | OPTD6_VACON_NX | 17 Dec, 2025 | 262.2 KB | .zip | |

| Eplan drawing | OPTD7_VACON_NX | 17 Dec, 2025 | 255.1 KB | .zip |

Software

| Type | Software Characteristic | Name | Version | Language | Released | Status | Download | File type |

|---|---|---|---|---|---|---|---|---|

| Software tools | SISTEMA Library for Danfoss Drives | 2.0 | English | 14 Jul, 2025 | Released | 842.2 KB | .zip | |

| Application software | VACON NXP Active Front End I | 153 | English | 12 May, 2022 | Released | 3.7 MB | .zip | |

| System software | AC drive firmware | VACON NXP Firmware | 211 | Arabic; Bulgarian; Czech; Danish; German; Greek (modern); English; Spanish, Castilian; Estonian; Persian; Finnish; French; Irish; Hebrew (modern); Hindi; Croatian; Hungarian; Indonesian; Icelandic; Italian; Japanese; Kazakh; Korean; Lithuanian; Latvian; Macedonian; Norwegian Bokmål; Dutch, Flemish; Polish; Portuguese; Romanian, Moldavian, Moldovan; Russian; Slovak; Slovenian; Serbian; Swedish; Tamil; Thai; Turkish; Ukrainian; Vietnamese; Chinese | 25 Aug, 2025 | Released | 4.3 MB | .zip |

| System software | Option and fieldbus firmware | VACON® Advanced Safety Option Firmware | 004 | English | 15 Dec, 2019 | Released | 3.1 MB | .zip |

| Software tools | VACON® NCDrive | 2.0.42 | English | 07 Mar, 2022 | Released | 5.0 MB | .zip | |

| Software tools | VACON® NCLoad | 1.0.34 | English | 03 Dec, 2020 | Released | 3.6 MB | .zip | |

| System software | Fieldbus configuration file | VACON® NX OPTC3/C5 PROFIBUS GSD | 01 | English | 10 Jan, 2016 | Released | 748.0 B | .zip |

| System software | Fieldbus configuration file | VACON® NX OPTC4 LonWorks XIF | 01 | English | 10 Jan, 2016 | Released | 1.3 KB | .zip |

| System software | Fieldbus configuration file | VACON® NX OPTC6 CANopen EDS | 01 | English | 26 Feb, 2018 | Released | 2.7 KB | .zip |

| System software | Fieldbus configuration file | VACON® NX OPTC7 DeviceNet EDS | 01 | English | 31 Dec, 2011 | Released | 3.5 KB | .zip |

| System software | Fieldbus configuration file | VACON® NX OPTCP PROFINET GSDML | 01 | English | 18 Feb, 2015 | Released | 7.4 KB | .zip |

| Application software | Drive software | VACON® NXP Active Front End II | 077 | English | 19 Nov, 2025 | Released | 2.5 MB | .zip |

| Application software | VACON® NXP Advanced Application | 242 | English | 04 Jul, 2023 | Released | 3.0 MB | .zip | |

| Application software | VACON® NXP Brake Chopper Unit | 126 | English | 02 Jul, 2023 | Released | 1.2 MB | .zip | |

| Application software | Drive software | VACON® NXP Crane Application | 106 | English | 19 Nov, 2025 | Released | 5.8 MB | .zip |

| Application software | VACON® NXP DC/DC Converter Application | 114 | English | 28 Jan, 2024 | Released | 1.7 MB | .zip | |

| Application software | VACON® NXP Generator Application | 137 | English | 28 Jan, 2024 | Released | 2.5 MB | .zip | |

| Application software | Drive software | VACON® NXP Grid Converter + GGC | 178 | English | 19 Nov, 2025 | Released | 5.5 MB | .zip |

| Application software | VACON® NXP Grid Converter + GGC (UL508a) | 103 | English | 30 Jul, 2020 | Released | 5.6 MB | .zip | |

| Application software | Drive software | VACON® NXP Lift Application | 229 | English | 19 Nov, 2025 | Released | 780.1 KB | .zip |

| Application software | VACON® NXP Line Sync II Application | 120 | English | 03 Jun, 2021 | Released | 2.6 MB | .zip | |

| Application software | Drive software | VACON® NXP Marine Application | 248 | English | 30 Nov, 2025 | Released | 6.2 MB | .zip |

| Application software | Drive software | VACON® NXP Power Generation Application | 041 | English | 19 Nov, 2025 | Released | 956.7 KB | .zip |

| Application software | VACON® NXP Shaft Sync Application | 115 | English | 22 Sep, 2010 | Released | 3.1 MB | .zip | |

| Application software | VACON® NXP System Interface Application | 244 | English | 23 Apr, 2019 | Released | 1.9 MB | .zip | |

| Application software | Drive software | VACON® NXP System Interface II Application | 114 | English | 13 Jan, 2026 | Released | 6.2 MB | .zip |

| Application software | Drive software | VACON® NXP uGrid Converter Application | 196 | English | 19 Nov, 2025 | Released | 3.4 MB | .zip |

| System software | Option and fieldbus firmware | VACON® OPT-C2 Modbus RTU / N2 Firmware | 023 | English | 11 Sep, 2012 | Released | 62.8 KB | .zip |

| System software | Option and fieldbus firmware | VACON® OPT-C3/C5 PROFIBUS DP Firmware | 018 | English | 06 Oct, 2015 | Released | 57.6 KB | .zip |

| System software | Option and fieldbus firmware | VACON® OPT-C4 LonWorks Firmware | 025 | English | 13 Jun, 2017 | Released | 66.1 KB | .zip |

| System software | Option and fieldbus firmware | VACON® OPT-C6 CANopen Firmware | 026 | English | 20 Aug, 2017 | Released | 74.5 KB | .zip |

| System software | Option and fieldbus firmware | VACON® OPT-C7 DeviceNet Firmware | 012 | English | 17 Sep, 2012 | Released | 81.8 KB | .zip |

| System software | Option and fieldbus firmware | VACON® OPT-CG S2 Protocol Firmware | 010 | English | 18 Sep, 2012 | Released | 46.3 KB | .zip |

| System software | Option and fieldbus firmware | VACON® OPT-CI Modbus TCP/IP Firmware | 020 | English | 12 Apr, 2021 | Released | 153.1 KB | .zip |

| System software | Option and fieldbus firmware | VACON® OPT-CJ BACnet MS/TP Firmware | 013 | English | 18 Sep, 2012 | Released | 64.8 KB | .zip |

| System software | Option and fieldbus firmware | VACON® OPT-CP PROFINET IO Firmware | 014 | English | 12 Apr, 2021 | Released | 511.6 KB | .zip |

| System software | Option and fieldbus firmware | VACON® OPT-CQ Ethernet/IP Firmware | 008 | English | 12 Apr, 2021 | Released | 188.3 KB | .zip |

| System software | Option and fieldbus firmware | VACON® OPT-E6 CANopen Firmware | 015 | English | 16 Sep, 2025 | Released | 2.6 MB | .zip |

| System software | Option and fieldbus firmware | VACON® OPT-E9 DualPort Ethernet Firmware | 014 | English | 16 Sep, 2025 | Released | 16.3 MB | .zip |

| System software | Option and fieldbus firmware | VACON® OPT-EC EtherCAT Firmware | 005 | English | 11 Aug, 2022 | Released | 2.9 MB | .zip |

| System software | Option and fieldbus firmware | VACON® OPTBB EnDat Firmware | 009 | English | 24 Nov, 2025 | Released | 62.6 KB | .zip |

| System software | Fieldbus configuration file | VACON® OPTBE EnDat/SSI/BiSS C Firmware | 010 | English | 27 Mar, 2019 | Released | 36.4 KB | .zip |

| System software | Fieldbus configuration file | VACON® OPTCQ EtherNet/IP EDS | 01 | English | 07 Jan, 2015 | Released | 13.2 KB | .zip |

| System software | Firmware | VACON® OPTE2/E8 RS485 MultiProtocol | 004 | English | 16 Sep, 2025 | Released | 2.2 MB | .zip |

| System software | Fieldbus configuration file | VACON® OPTE3/E5 PROFIBUS GSD | 01 | English | 07 Jun, 2022 | Released | 13.4 KB | .zip |

| System software | Library | VACON® OPTE3/E5 TIA Portal Library | 014 | English | 07 Jul, 2020 | Released | 3.6 MB | .zip |

| System software | Fieldbus configuration file | VACON® OPTE9 EtherNet/IP EDS | 01 | English | 02 Sep, 2020 | Released | 72.1 KB | .zip |

| System software | Fieldbus configuration file | VACON® OPTE9 PROFINET IO GSDML | 01 | English | 02 Apr, 2020 | Released | 204.3 KB | .zip |

| System software | Fieldbus configuration file | VACON® OPTE9 SIMATIC PDM EDD | 01 | English | 15 Dec, 2019 | Released | 667.4 KB | .zip |

| System software | Library | VACON® OPTE9-EA TIA Portal Library | 01 | English | 15 Feb, 2018 | Released | 2.9 MB | .zip |

| System software | Library | VACON® OPTE9/EA EtherNet/IP Add-on Instructions | 01 | English | 15 Feb, 2018 | Released | 531.9 KB | .zip |

| System software | Option and fieldbus firmware | VACON® OPTEA Advanced Dual Port Ethernet Firmware | 011 | English | 25 Nov, 2025 | Released | 16.8 MB | .zip |

| System software | Configuration file | VACON® OPTEA PROFINET IO GSDML | 2.43 | English | 01 Dec, 2025 | Released | 242.5 KB | .zip |

| System software | Fieldbus configuration file | VACON® OPTEA SIMATIC PDM EDD | 01 | English | 12 Nov, 2018 | Released | 461.7 KB | .zip |

| System software | Fieldbus configuration file | VACON® OPTEC EtherCAT ESI | 01 | English | 19 Feb, 2020 | Released | 381.4 KB | .zip |

| System software | Library | VACON® PROFISAFE TIA Portal Library | 01 | English | 15 Feb, 2018 | Released | 2.4 MB | .zip |

| Software tools | VACON® Safe | 1.0.4.0 | English | 24 Jan, 2021 | Released | 3.8 MB | .zip |

Related applications

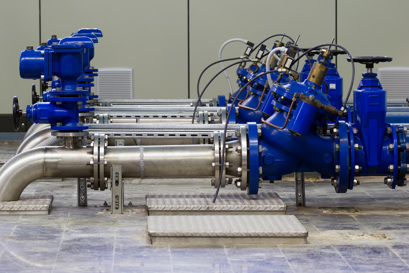

Compressors, wind turbines, extruders, pumps, fans, conveyors, crushers, thrusters, and propulsion, test-bench, crane, winch and power-conversion systems.

To optimize crane performance, Danfoss offers flexible control strategies combined with energy efficiency, operating within stringent safety requirements.

By controlling industrial pumps with a Danfoss AC drive you can help optimize processes and significantly reduce energy and maintenance costs.

Draw upon expertise from Danfoss to optimize energy storage solutions on board vessels, and shore power supplies for quieter and cleaner harbors.

Case studies

CMAL ferries use 38% less fuel than conventional vessels and emissions are reduced by a similar amount.

The Telstar saves 20% on operating costs compared to traditional tugboats.

In 2009, Viking River Cruises commissioned the MV Viking Legend, the world’s first river cruiser with an energy and drive system based on a highly efficient DC bus. Since then they have built up a fleet of more than 50 hybrid ships.

Venturing into hybrid propulsion was a bold step for the Vranken family’s dry cargo bulk carrier business, which serves the inland waterways of the Rhine. It has paid off fast, delivering rock-bottom operating costs, thanks to an innovative diesel-electric propulsion system.

On board the MS Nadorias, the huge potential in converting to hybrid is no longer a vision but a reality. A hybrid retrofit has given this inland container carrier a huge 15% saving not only in fuel, but also in CO2 emission. Since the main diesel engine now runs much less, there is 60% less maintenance cost and higher uptime than for its identical sister ship.

Approvals

| Type | Name | Approval authority | Language | Valid for | Download | Expiration date | File type |

|---|---|---|---|---|---|---|---|

| Marine Certificate | ABS 24-2545447-1-PDA | English | Multiple | 114.8 KB | 15 May, 2029 | ||

| Marine Certificate | BKI 00337TA19 | English; Indonesian | Multiple | 480.4 KB | 01 Oct, 2029 | ||

| Marine Certificate | BV 14584-DO BV | English | Multiple | 612.1 KB | 14 Sep, 2026 | ||

| Marine Certificate | BV 30847-C1 BV | English | Multiple | 1.1 MB | 28 Dec, 2027 | ||

| EU Declaration | Danfoss EU DPD02212.C | English | Multiple | 1.1 MB | 20 Apr, 2026 | ||

| Manufacturer's Declaration | Danfoss MD 00773531.A2 | English | Multiple | 199.1 KB | 27 Oct, 2026 | ||

| EU-UK Declaration | Danfoss+ 00737164 | English | Multiple | 148.7 KB | 02 Jul, 2028 | ||

| Manufacturer's Declaration | Danfoss+ID00733878B1 | English | Multiple | 102.3 KB | 03 Jul, 2028 | ||

| Marine Certificate | DNV GL TAE000013B Rev. 4 | English | Multiple | 736.5 KB | 30 Dec, 2028 | ||

| Electrical Safety Certificate | IFA 2401125 | English | Multiple | 343.8 KB | 27 May, 2029 | ||

| Marine Certificate | KR HMB 28683-AC001 | English | Multiple | 311.0 KB | 26 Jul, 2029 | ||

| Marine Certificate | KR HMB28683-AC003 | English | Multiple | 297.7 KB | 19 Dec, 2026 | ||

| Marine Certificate | LR21105721TA | English | Multiple | 799.2 KB | 10 Apr, 2026 | ||

| Marine Certificate | NKTA25199M | English | Multiple | 4.4 MB | 05 Apr, 2030 | ||

| Marine Certificate | RINAELE042725XP | English | Multiple | 1.6 MB | 26 Mar, 2030 | ||

| Electrical Safety Certificate | UL E171278 | English | Multiple | 282.5 KB |