This 720 Mtpd nitric acid plant in South Africa saves 3.6 M Rand annually on operating costs, thanks to an upgrade from direct-on-line operation to VLT® drive control of electric pumps and motors.

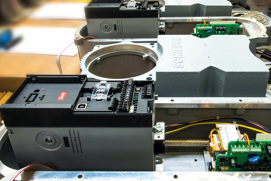

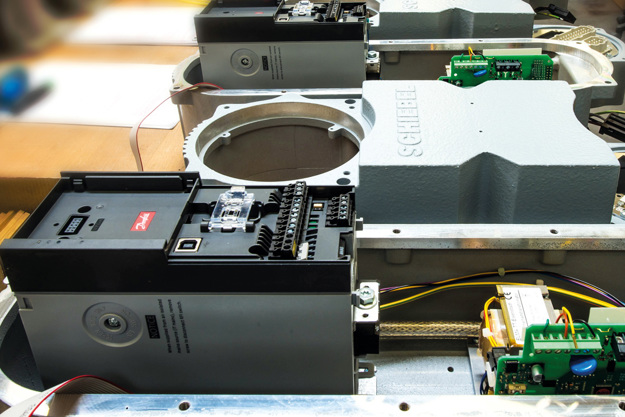

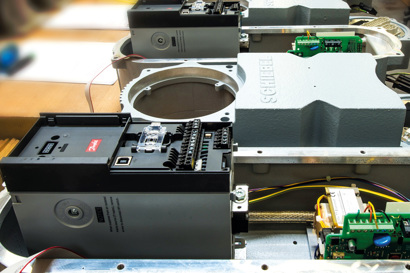

For many years, motors and pumps in the process cooling water (PCW) system operated direct-on-line. With the upgrade, AEL Intelligent Blasting aimed to improve efficiency and reliability by introducing AC drive motor control. They chose VLT® AQUA Drive FC 202 and VLT® HVAC Drive FC 102 drives from Danfoss, based on their ability to ensure stable operation despite unreliable mains power supply. These drives offer Automatic Energy Optimization and kinetic back-up features to support highly efficient and reliable plant operation.

The remarkable payback time of only 18 months reflects the vast improvement in process cooling water efficiency enjoyed by AEL Intelligent Blasting.

“The drives were selected based on the kinetic back-up feature, which is valuable to us because of our unstable electricity supply and a lot of small voltage dips causing our facilities to trip out. With this feature we can keep the plant online without any issues, therefore saving millions,” explains Johan Engelbrecht, AEL Nitrates MV Electrical Engineer.

Get more information

Read about VLT® AQUA Drive

Read about VLT® HVAC Drive

Read about Danfoss solutions for chemical industries

Read about Danfoss solutions for the mining industry:

- conveyors

- cranes

- pumps

- underground ventilation

Other case studies related to pumps

-

if (isSmallPicture) {

Decarbonizing the dredge: Electrified high-pressure pump for horizontal drilling

Decarbonizing the dredge: Electrified high-pressure pump for horizontal drillingNETHERLANDS: B&P Electric Motors electrified its mobile high-pressure pump unit for horizontal drilling. VACON® NXP Liquid Cooled drives ensure high efficiency and resilience in harsh conditions, when forcing soil through pipes up to 3km long.

-

if (isSmallPicture) {

DrivePro® reduces cost, downtime, and failure rate for Dahe Paper Group

DrivePro® reduces cost, downtime, and failure rate for Dahe Paper GroupCHINA: Thanks to several Danfoss DrivePro® services, Dahe Paper Group, a state-owned paper mill company in China, has reduced its costs, downtime, and failure rate.

-

if (isSmallPicture) {

DrivePro® services enhance security of heat supply for 49,000 apartments in Gliwice

DrivePro® services enhance security of heat supply for 49,000 apartments in GliwicePOLAND: At district heating company PEC Gliwice, AC drives reduce energy consumption of electric motors by up to 40%. DrivePro® Site Assessment audits help ensure optimal efficiency.

-

if (isSmallPicture) {

VACON® 1000 MV drives power deep pumping at Los Gatos mine

VACON® 1000 MV drives power deep pumping at Los Gatos mineMEXICO: Faced with the challenge of pumping stagnant water from depths of more than 400 meters, the Cerro Los Gatos mine opted for medium-voltage variable speed pump control using the VACON® 1000 drive from Danfoss. Drives were delivered and installed in the record time of 14 weeks from factory acceptance test.

-

if (isSmallPicture) {

Danfoss efficiencies help South African farmer to free up energy and achieve production goals

Danfoss efficiencies help South African farmer to free up energy and achieve production goalsSOUTH AFRICA: Discover how a South African farmer achieves 155,000+ kWh in annual energy savings thanks to a collaboration between Danfoss and BMG.

-

if (isSmallPicture) {

VLT® Midi Drive for precise actuator control

VLT® Midi Drive for precise actuator controlWith its compact and temperature-resistant design, the drive integrates easily into actuators from Schiebel Antriebstechnik GmbH, providing high-precision flow control.