GERMANY: Low voltage drives enhance machine processes to improve efficiency and productivity, with precision, speed, and accuracy benefits. For manufacturing companies such as WEBER, this can lead to lower energy consumption and running costs.

More efficient manufacturing

Discover how WEBER saves 15% on energy consumption using VLT® AutomationDrive FC 302

Leading Bavarian manufacturer Hans Weber Maschinenfabrik GmbH was looking for drives that could improve the efficiency of its grinding machines, whilst maintaining the renowned high-quality finish given to every product, be it metal or wood.

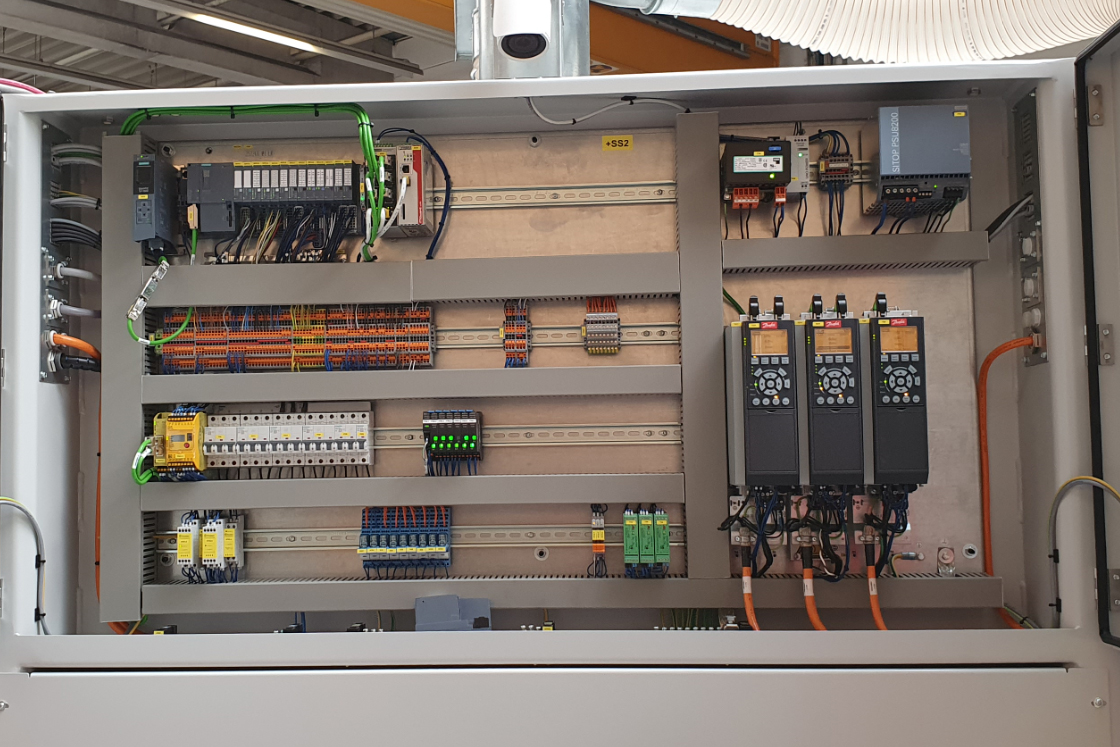

But with limited space in the machine control cabinets, WEBER needed a small solution that could deliver big benefits, and the compact VLT® AutomationDrive FC 302 was the perfect fit.

A wide variety of motor technologies are installed in the grinding machines, from induction to permanent magnet motors, all operated by the same type of drive.

Grinding units need to work with the greatest speed, accuracy, and stability to ensure precision on the grinding surface. WEBER therefore needed low voltage drives that could keep the motor at a constant speed to achieve an optimal grinding pattern.

Up to 13 VLT® drives were installed to control different parts within the grinding machines, such as the sanding unit, position controller, vacuum table, and conveyor belt.

15% reduction in energy consumption

WEBER utilizes Eco Drive technology, where the Danfoss drives automatically recognize the load on the respective grinding unit and regulate optimal processes and ranges of action. This reduces losses in the drive system and enables energy savings of around 15%.

The compact VLT® AutomationDrive FC 302 maximizes available space in the control cabinet as it does not require any additional electrical components, electromagnetic compatibility filters or chokes.

WEBER also benefits from DrivePro® Remote Expert Support, a maintenance service that provides easy, fast and secure access to all drives. In the event that a fault arises, Danfoss can support customers around the world.

Danfoss is committed to providing the highest levels of customer service. A permanent support team made up of application engineers, service technicians, salespeople and back-office employees is available to ensure Hans Weber machines stay up and running at all times.

“We have worked with Danfoss for a long time and the cooperation has always gone well. They know their way around our products and they know us. They understood exactly what we needed and we received drives that were perfectly suited to our requirements. The Danfoss VLT® AutomationDrive FC 302 supports our high-precision grinding machines but most importantly it enables us to reduce energy consumption and operating costs.”

- Stefan Fischer, Head of Electrical Design at Hans Weber

Related products

-

if (isSmallPicture) {

VLT® AutomationDrive FC 301 / FC 302

VLT® AutomationDrive FC 301 / FC 302The VLT® AutomationDrive FC 301 / FC 302 is designed for variable speed control of all asynchronous motors and permanent magnet motors. It comes in a standard version (FC 301) and an advanced high dynamic version (FC 302) with additional functionalities.

Related case stories

-

if (isSmallPicture) {

DrivePro® services ensure reliable uptime for Sapio Group

DrivePro® services ensure reliable uptime for Sapio GroupITALY: Sapio Group, Italy's leading producer of industrial and medical gases, uses condition monitoring (CBM) and DrivePro® services to ensure reliable uptime for gas supply to a semiconductor manufacturer.

-

if (isSmallPicture) {

Roca Group factory drives down energy consumption by 30%

Roca Group factory drives down energy consumption by 30%POLAND: By investing in Danfoss VLT® drives, the Roca Group sanitary ware factory in Gliwice now consumes about 30% less energy, annually.

-

if (isSmallPicture) {

iC7-Automation: Boosting HDD performance by electrification

iC7-Automation: Boosting HDD performance by electrificationNETHERLANDS: This horizontal directional drilling rig is more energy efficient and performance has improved, after electrification using AFE drives and EDITRON motors from Danfoss.

-

if (isSmallPicture) {

Decarbonizing the dredge: Electrified high-pressure pump for horizontal drilling

Decarbonizing the dredge: Electrified high-pressure pump for horizontal drillingNETHERLANDS: B&P Electric Motors electrified its mobile high-pressure pump unit for horizontal drilling. VACON® NXP Liquid Cooled drives ensure high efficiency and resilience in harsh conditions, when forcing soil through pipes up to 3km long.

-

if (isSmallPicture) {

DrivePro® reduces cost, downtime, and failure rate for Dahe Paper Group

DrivePro® reduces cost, downtime, and failure rate for Dahe Paper GroupCHINA: Thanks to several Danfoss DrivePro® services, Dahe Paper Group, a state-owned paper mill company in China, has reduced its costs, downtime, and failure rate.

-

if (isSmallPicture) {

IMC: A reliable and efficient alternative to servo technology

IMC: A reliable and efficient alternative to servo technologyNETHERLANDS: Discover how Huwa International Pipeline Products improved worker safety and reduced lead times on its pickling line with Danfoss VLT® AutomationDrive FC 302 and its Integrated Motion Controller (IMC).