There’s no room for error in the world of pharmaceuticals. And that means there’s certainly no room for downtime within the mechanical systems of a continuous production cycle. For these aseptic environments, HVAC plays a critical role in maintaining the highly controlled temperature and air quality. And while it may only take an hour to repair a potential system breakdown, it takes many more to reestablish the aseptic environment—which means many costly hours of lost production time. Hence, a leading global pharmaceutical company was determined to find an intelligent HVAC solution that prevents downtime with real-time system monitoring and customizable instant alarms. Plus, the solution needed to fit within the organization’s ambitious digitalization strategy.

Uptime you can rely on

Discover how the Danfoss VLT® HVAC Drive FC 102 with integrated condition-based monitoring protects aseptic environments.

Maintaining an aseptic environment is critical to pharmaceutical production. And for a Denmark based pharmaceutical company, integrated digital solutions are the key to achieving its ambition for safe and continuous production processes backed by its mechanical systems.

In this case, the focus was on the HVAC system. An HVAC breakdown could instantly contaminate the manufacturing operations—regardless of how minor the issue is. And that could cost the company millions in lost revenue—due to lost production—for every hour it takes to reestablish the aseptic environment.

“For us, predictability is essential to maintaining 24/7 production—which is why the monitoring and control of our HVAC system is key to to preventing downtime,” explains the project’s Utility Engineer. So, that called for an intelligent solution giving onsite technicians real-time monitoring of the vibration inside an air handling ventilation system—calibrated to send alarms precisely before a breakdown occurs.

Challenge

Danfoss was brought in to collaborate on a digital solution that could help the pharmaceutical company:

- Prevent downtime with real-time monitoring

- Instantly react to system irregularities with warnings and alarms integrated into their production SCADA system and their Building Management System

- Increase overall production reliability and safety

- Support an ambitious digitalization agenda

With a zero-tolerance for bacterial contamination and the ambition for zero downtime, the challenge was defined. In order to find the best solution, the pharmaceutical company tested three different vibration setups for the HVAC system. The purpose of the experiment was to find the solution that met their special requirements. Specifically, instant, actionable insights that enable preventive maintenance. The project’s Utility Engineer explained, “Data empowers us to make informed decisions previously based on gut feelings.” With that objective in place, the experiment began.

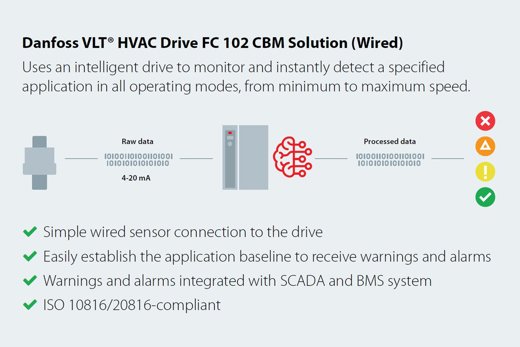

Danfoss proposed the VLT® HVAC Drive FC 102 with integrated condition-based monitoring (CBM) for the pharmaceutical company’s HVAC system. A CBM solution empowers the drive to act as a smart sensor, monitoring the condition of a motor and application for early detection of potential problems—such as mechanical vibration inside an AHU. That means the intelligent drive not only produces data—it interprets data into actionable insights for preventative maintenance.

Testing the Danfoss CBM solution on an AHU application

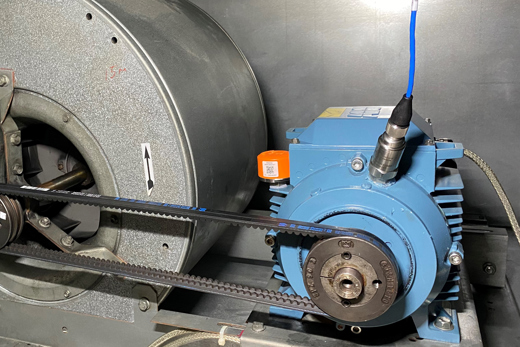

The pharmaceutical company’s engineering team built an AHU fan system to evaluate the different vibration solutions. Vibration irregularities were built in to simulate real-time changes in the AHU and monitor the detection solutions’ performance using two controlled factors: a damaged ball-bearing and motor imbalance. Before implementing the fault conditions, the engineers defined a healthy system baseline in the Danfoss CBM solution—calibrated in an intuitive App. The baseline and its warning and alarm thresholds reflects how the CBM will react to changes in the specified application and document the real-time accuracy of the CBM. The CBM baseline is often the first indication of an application’s operating stability. Plus, when a contractor completes a new installation, the baseline provides a service case for troubleshooting because it monitors the application’s operating condition from the lowest to the highest speed.

Maximum uptime backed by predictable maintenance

Out of the three systems tested, the Danfoss CBM solution was the only one to succeed in capturing the damage to the AHU test rig at the exact moment the faults were introduced into the application. Because the CBM solution succeeded in reporting real-time warnings and alarms, it proved that the on-site technicians could prevent costly downtime—instead of reacting to an automatic shutdown.

The pharmaceutical company’s simulated AHU vibration test proved that the VLT® HVAC Drive FC 102 with integrated condition-based monitoring (CBM) technology supported the factory’s aseptic operating conditions and aligned with their digitalization strategy. With intuitive commissioning, easy installation, and real-time monitoring and alarms, the Danfoss CBM solution effectively erased the threat of downtime and contamination.

“There are some things even scheduled maintenance can’t detect—such as a worn-down ball-bearing. With the Danfoss CBM solution, we get an intelligent drive that prevents costly downtime,” concluded the Utility Engineer.

The pharmaceutical company now has the confidence to implement CBM on an industrial scale in their operations with the knowledge that their production facility can operate safely and reliably

VLT® HVAC Drive

Get intelligence, reliability and low total cost of ownership (TCO) in your heating, ventilation and air-conditioning installations, with this unique drive optimized for building automation systems.

More case stories

-

if (isSmallPicture) {

Pumping smarter, not harder with intelligent drives for maximized indoor comfort

Pumping smarter, not harder with intelligent drives for maximized indoor comfortUSA: With integrated condition monitoring, VLT® HVAC Drive FC 102 optimizes hydronic system uptime to enhance indoor climate at a community healthcare facility in Wisconsin.

-

if (isSmallPicture) {

Wind tunnel achieves 99.5% uptime with Danfoss DrivePro®

Wind tunnel achieves 99.5% uptime with Danfoss DrivePro®Belgium: Thanks to Danfoss DrivePro® services, LuxFly has achieved 99,5% uptime in Europe’s largest vertical wind tunnel that is used for skydiving.

-

if (isSmallPicture) {

Digitalization drives energy savings at Centro Carni Company

Digitalization drives energy savings at Centro Carni CompanyITALY: Digitized shock freezing systems helped Centro Carni Company improve productivity and quality, with less power consumption and more streamlined maintenance.

-

if (isSmallPicture) {

TechnoAlpin’s snow-making plant ensures perfect snow when and where it’s needed

TechnoAlpin’s snow-making plant ensures perfect snow when and where it’s neededCHINA: TechnoAlpin SpA’s snow-making plant and Danfoss VLT® AC drives will shift 330,000 m3 of water that will be turned into perfect snow.

-

if (isSmallPicture) {

EC+ Concept drives optimal air conditioning at Volkswagen’s Navarra factory

EC+ Concept drives optimal air conditioning at Volkswagen’s Navarra factorySPAIN: Highly efficient axial fans controlled by VLT® HVAC Drive FC 102 at Volkswagen Navarra, Spain, delivered 20% energy savings in AHU operation.

-

if (isSmallPicture) {

MS Cinderella saves more than 1000 tpa marine diesel with new ventilation control

MS Cinderella saves more than 1000 tpa marine diesel with new ventilation controlSWEDEN: Aboard the Viking Lines cruise ship M/S Cinderella, Danfoss AC variable speed drives are delivering fuel savings so large that the cost of installing the drives will be fully recovered in less than eighteen months.