This is a success story about the Danfoss Intelligent Purging System IPS 8 and SW40A Semi-Welded Plate and Frame Heat Exchanger in use at Miratorg’s automated cold storage project in Kursk.

Since Miratorg Agribusiness Holding was established in 1995, the company has become a leading Russian meat producer and supplier. Its new automated cold storage in Kursk will store 20,000 tons of frozen products.

The storage facility is equipped with a single-stage ammonia refrigeration system with an economizer. The ammonia refrigeration system contains four Mycom screw compressors and can maintain two temperature levels.

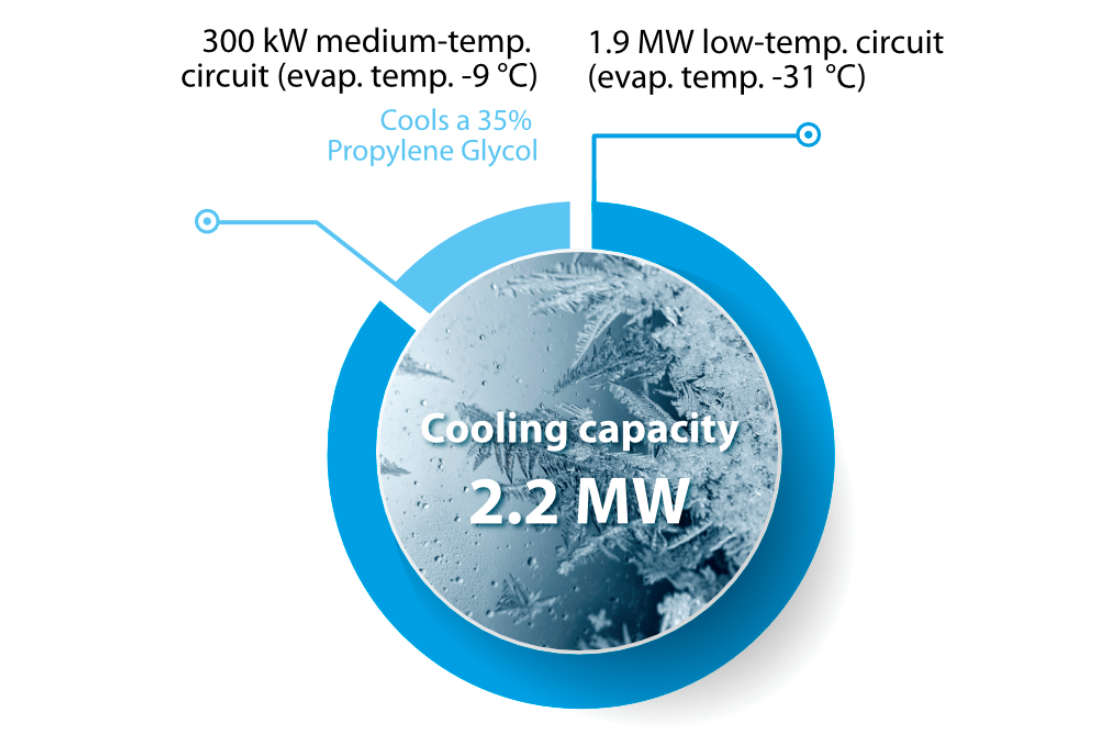

The system’s total cooling capacity is 2.2 MW. Of this, 1.9 MW is consumed by the low-temperature circuit (evaporating temperature -31 °C), while 300 kW is consumed by the medium-temperature circuit (evaporating temperature -9 °C), which cools a 35% Propylene Glycol.

OK LLC was responsible for designing, delivering, installing, and commissioning the ammonia refrigeration system.

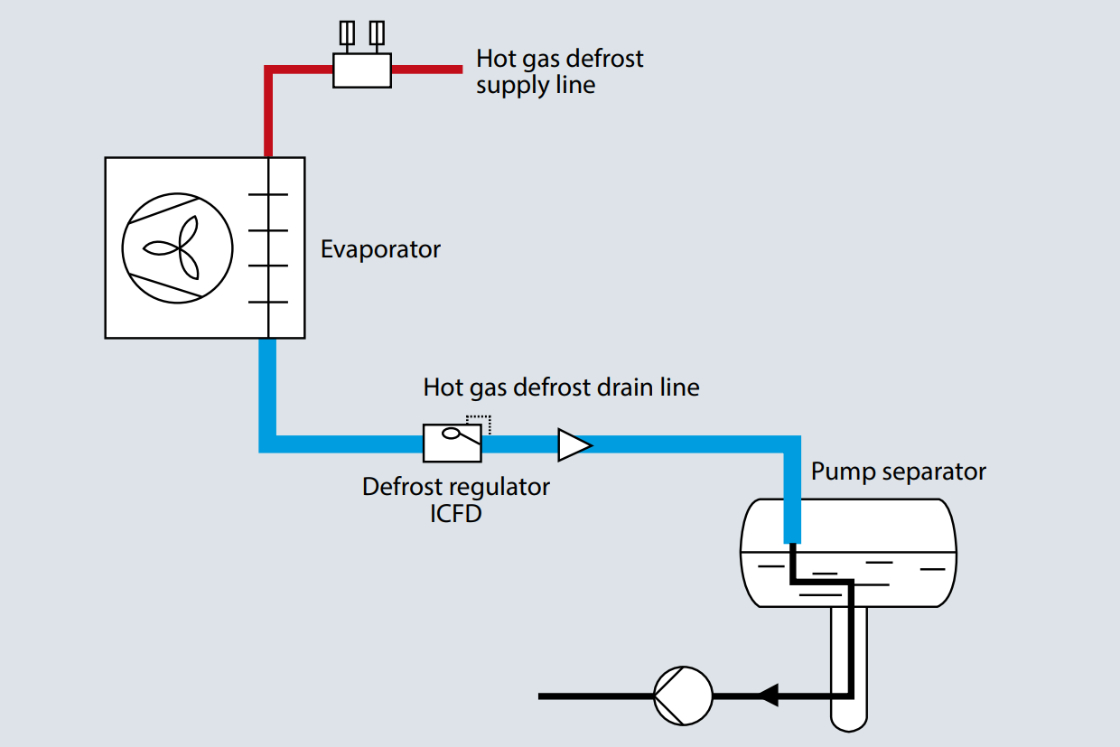

The advanced technical solution chosen by OK LLC uses the combined ICF valve stations for ammonia air coolers with hot gas defrosting. This enabled the number of welds to be reduced up to 4 times.

The two-stage hot gas supply to the low-temperature evaporators through the ICSH valves (part of the ICF stations) ensures a smooth transition to defrost mode, reducing initial hydraulic pulsations and improving the safety of the evaporators.

The used technical solution also enabled highly efficient control of the evaporator’s level-based defrosting process with the ICFD float module. This significantly reduces the refrigerant’s vapor quality and fully utilizes the latent condensing heat throughout the entire defrost period, reducing the amount of bypass vapor (up to 90%), the total defrost time, and the overall compressor load.

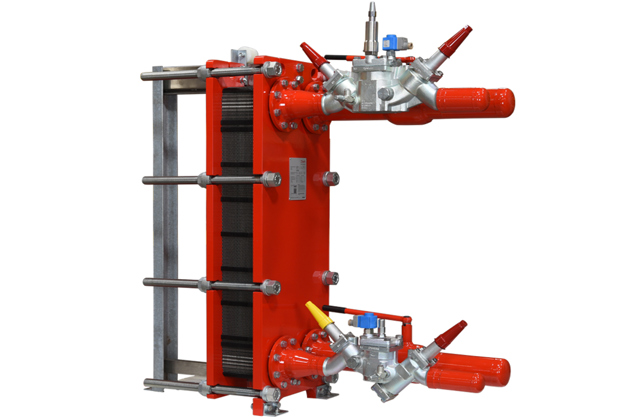

The Danfoss Semi-Welded Plate and Frame Heat Exchanger SW 40A-90-TL is used as a flooded evaporator that cools 35% Propylene Glycol solution. The Follower (movable frame plate) has a nylon roller that provides easy access to the plate pack and reduces the likelihood of sparking at the carrying bar area.

The heat exchanger plate pack consists of 0.6 mm-thick AISI 304 stainless steel plates. The start and end single plates are 0.7 mm-thick and made of AISI 316L stainless steel, as are the lining connections on the Header (fixed frame plate). The thicker single plates and the AISI 316L linings are both standard options that improve the unit’s construction rigidity and extend its life span.

The heat exchanger for evaporator application was jointly selected by Danfoss and OK LLC specialists. The unit complied with all the specifications and recommendations, including for pressure loss, heat exchange surface margin, and shear stress. By working closely together, the personnel was able to meet the delivery deadlines, quickly pass through comprehensive test program, successfully start up the unit, and minimize the risk of fouling during its future use.

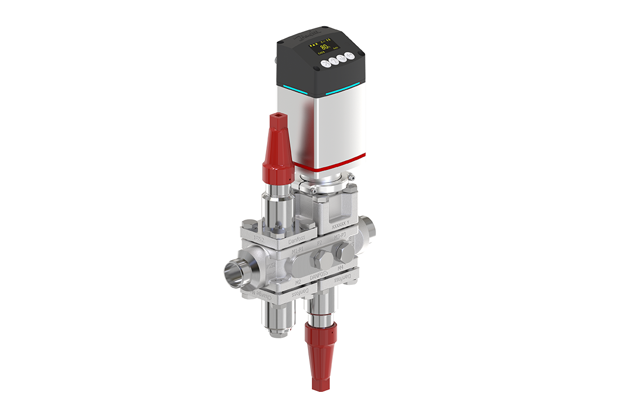

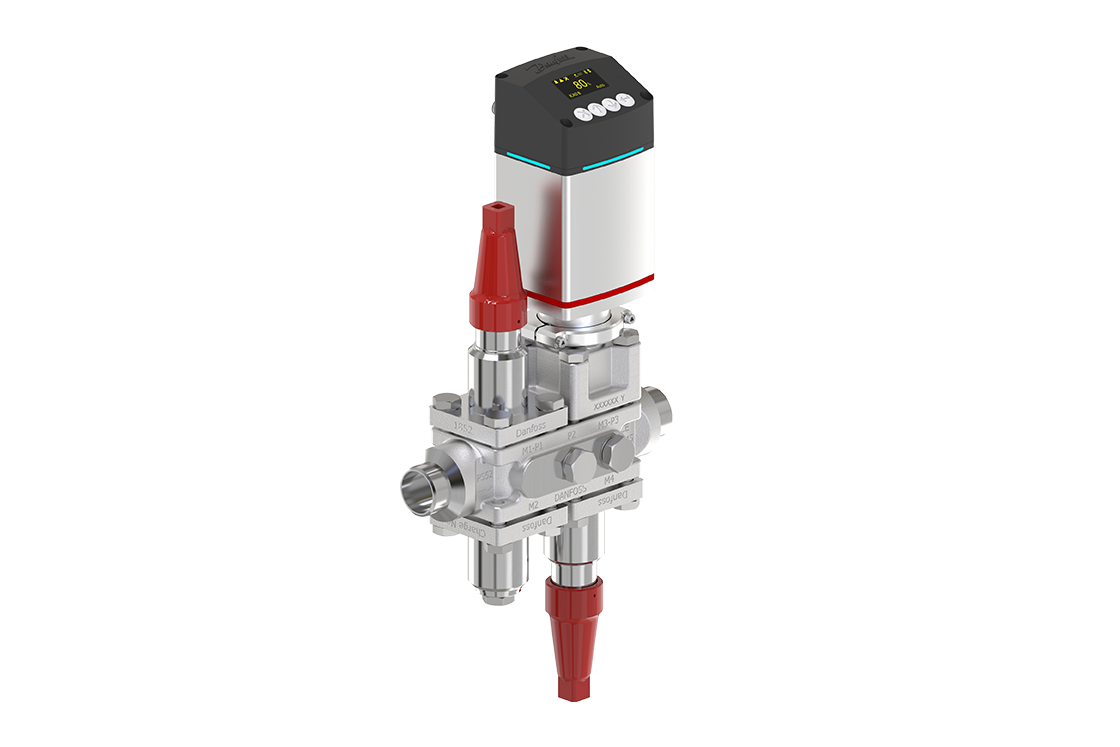

The Danfoss Intelligent Purging System IPS 8 removes the noncondensable gases from the refrigeration system. Five purge points are connected to the air purger, four on the condenser’s group and the fifth on the line receiver.

The drainage of ammonia condensate from the air purger to the plant is organized through the SV3 float valve while the non-condensable gases are purged to a water tank.

For improved efficiency, the air purger IPS 8 uses the R452a refrigerant with a low evaporating temperature in its independent compressor unit, fine-tuned control logic, and a specially designed tube-in-tube heat exchanger. The air purger was successfully connected to a centralized PLC system for remote monitoring using the Modbus RTU protocol.

|

“During commissioning, the Intelligent Purging System IPS 8 let us verify whether the purging was functioning properly, and quickly identify the causes of any errors. Within a week of start-up, the air purger had removed the non-condensable gases from the refrigeration system and switched into the test mode. This confirmed the entire system was leak-free,” says K. Tushev, Chief Technology Officer at OK LLC “The development of Semi-Welded Plate and Frame Heat Exchangers and Intelligent Purging System IPS 8 for Industrial Refrigeration applications were the important projects for us. Expertise and use of advanced technologies have helped to create safe and energy-efficient products that meet today’s market needs. We would like to thank OK LLC for their professional attitude, use state-of-the art technologies, and trust to us in this major project,” says Dr. Evgeny Sukhov, IAR Member, Business Development Director, CIS and Eastern Europe, Danfoss Industrial Refrigeration. |

It is worth noting that, with its compact design, high IP55 protection rating, corrosion protection for components, and on-flammable refrigerant, the IPS 8 was able to be fitted in the ammonia machinery room to continuously remove the non-condensable gases from the refrigeration system.

Related Products

-

if (isSmallPicture) {

ICF Flexline™ valve station

ICF Flexline™ valve stationUnmatched freedom is the keyword of ICF Flexline™ valve stations. As part of the Flexline™ platform, these valve stations are based on a unique modular concept.

-

if (isSmallPicture) {

IPS 8: Intelligent purging system for industrial refrigeration

IPS 8: Intelligent purging system for industrial refrigerationWith its compact design and automatic purging functionality, the Danfoss intelligent purger system helps improve the operational safety, efficiency and cost-effectiveness of industrial refrigeration systems.

-

if (isSmallPicture) {

Semi-welded plate heat exchanger for industrial refrigeration ammonia applications

Semi-welded plate heat exchanger for industrial refrigeration ammonia applicationsThe semi-welded plate heat exchangers are optimized for industrial applications. The semi-welded plate heat exchangers from Danfoss is designed for ammonia systems and can be used for applications such as Condensers, flooded and pumped evaporators, Sub-coolers, Desuperheaters and Oil coolers.