High thermal performance

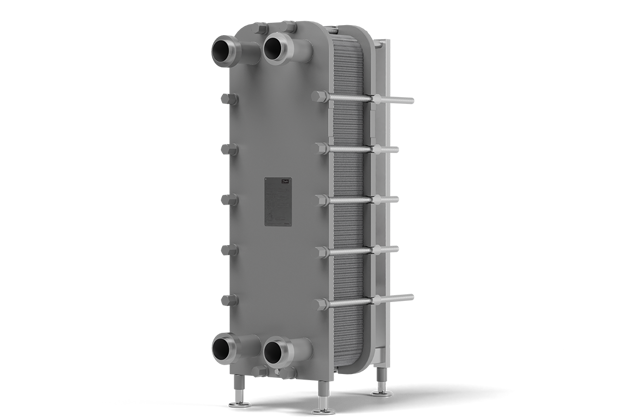

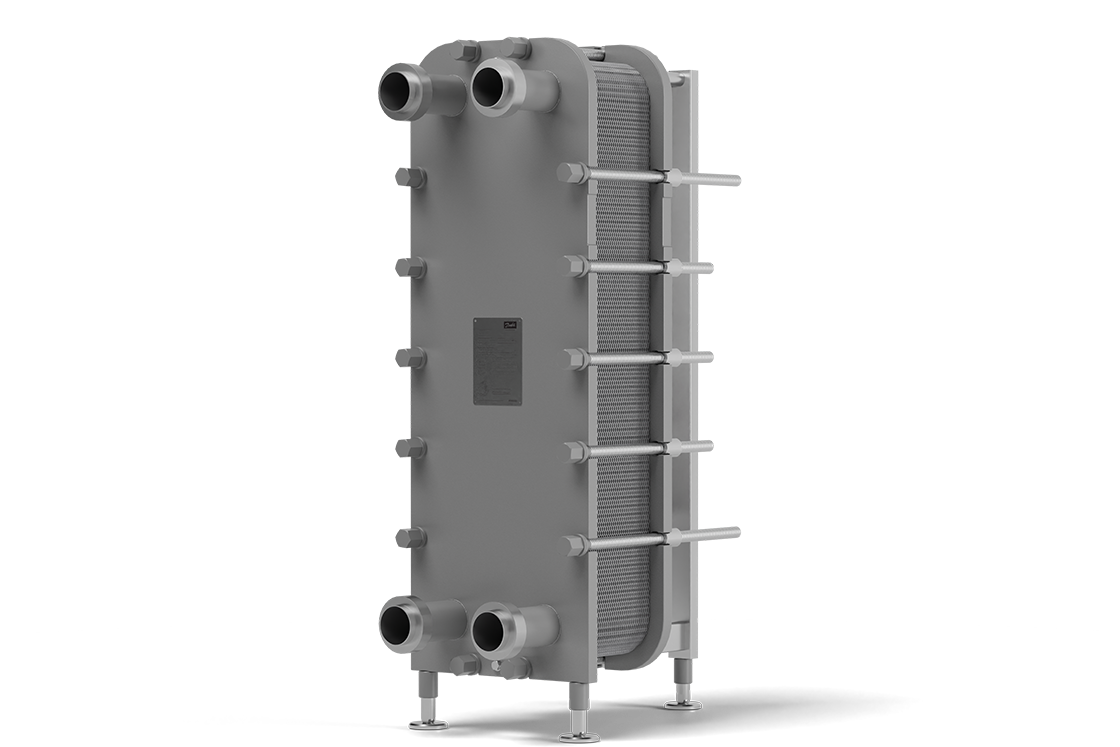

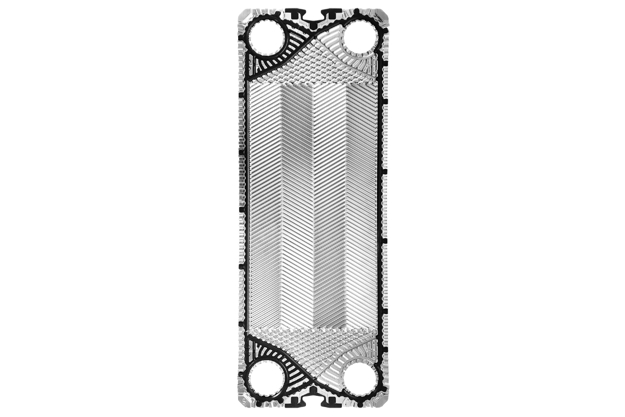

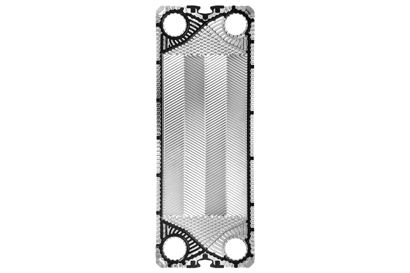

Our SONDEX® Fishbone plate pattern technology is used in the majority of our plate heat exchangers. The pattern is designed for high thermal performance while using the allowed pressure drop in the most efficient manner. Fishbone plate patterns are available with different pressing depths, pattern pitch and angles with each individual pattern optimized for a certain duty.

What does that mean for you?

Engineered to maximize turbulence, even at low flow rates, this pattern achieves unparalleled heat transfer. The pattern has proved its effectiveness through rigorous testing and is the default choice for plate heat exchangers.

Variants of the Fishbone pattern are designed to create different levels of turbulence, use a different pressure drop, and meet different thermal requirements. Each variant fills a particular niche, or is aimed at a certain type of duty. This flexibility allows us to optimally cover all your heat transfer needs, no matter the application.

Special features include a reinforced hanging system for better suspension, an optimized distribution area that prevents stagnant zones, a maximized heat transmission area for high performance, and the unique SONDEX® Alignment System that ensures proper plate pack stability and keeps the individual plates firmly in place in the assembled heat exchanger.

Features and benefits

Maximized heat transmission area, fine-tuned for each application, reduces the total number of plates needed for optimal performance. High efficiency lets you dial up performance and dial down your energy consumption.

Designed to ensure an even distribution of media across the entire plate and prevent stagnant zones, resulting in the best possible use of the pressure drop.

Unique gasket system that prevents misalignment of the plate pack and allows for easy assembly. The specially designed gasket groove preserves gasket elasticity and increases its lifetime.

Discover how the SONDEX® gasketed plate heat exchanger operates.

From design and construction to working principles, we take you through the key features behind these high-efficiency heat transfer solutions.

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Brochure | A world of heat exchangers | English | Multiple | 18 Nov, 2024 | 7.2 MB | |

| Brochure | A world of heat exchangers | Bulgarian | Bulgaria | 04 Oct, 2024 | 5.3 MB | |

| Brochure | A world of heat exchangers | Romanian, Moldavian, Moldovan | Romania | 10 Oct, 2024 | 9.7 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Polish | Multiple | 05 Jun, 2025 | 9.2 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | French | Multiple | 05 Jun, 2025 | 9.1 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Danish | Multiple | 05 Jun, 2025 | 9.1 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | German | Multiple | 05 Jun, 2025 | 9.2 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Chinese (CN) | Multiple | 05 Jun, 2025 | 9.6 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Hungarian | Multiple | 05 Jun, 2025 | 9.1 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Italian | Multiple | 05 Jun, 2025 | 9.1 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | Russian | Multiple | 17 May, 2024 | 16.5 MB | |

| Operating guide | Gasketed and semi-welded Plate type heat exchangers | English | Multiple | 02 Jun, 2025 | 9.6 MB | |

| Brochure | Gasketed plate heat exchangers - Next-generation heat transfer solutions | English | Multiple | 22 Nov, 2024 | 4.4 MB | |

| Brochure | SONDEX® Free Flow sugar brochure | English | Multiple | 27 Nov, 2024 | 7.2 MB | |

| Brochure | SONDEX® Traditional Plate Heat Exchangers | English | Multiple | 12 Feb, 2024 | 9.4 MB |

Related products

-

if (isSmallPicture) {

Sanitary plate heat exchangers

Sanitary plate heat exchangersSONDEX® sanitary plate heat exchangers are made for applications with strict hygienic requirements and use FDA compliant materials. We care greatly about your end product, and take the necessary steps to ensure the highest output quality. Each solution is designed based on your specifications to provide the perfect conditions for your product.

-

if (isSmallPicture) {

Standard plate heat exchangers

Standard plate heat exchangersSONDEX® standard plate heat exchangers are the ideal choice for a wide range of applications across numerous market segments. We have the largest plate portfolio in the world, and customize each heat exchanger to meet your exact requirements. Innovative technologies and smart design make our traditional plate heat exchangers a stellar investment.

-

if (isSmallPicture) {

D-plate technology

D-plate technologyOur Danfoss engineers have enhanced the way heat exchanger plates are designed with the introduction of the new D-plate series. Drawing on years of experience within heat transfer technology and deep application knowledge, we have made significant upgrades to the traditional Fishbone plates to truly redefine the way we think of heat exchanger plates.