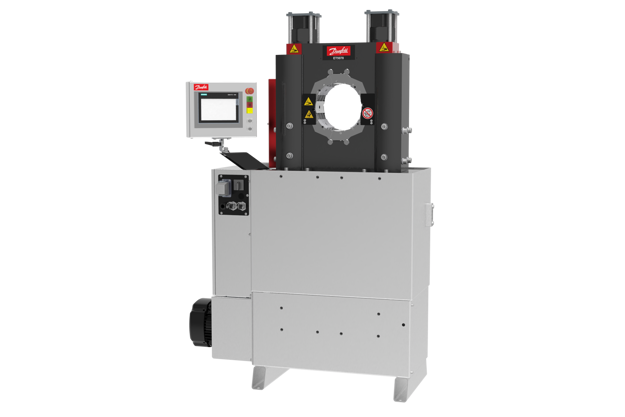

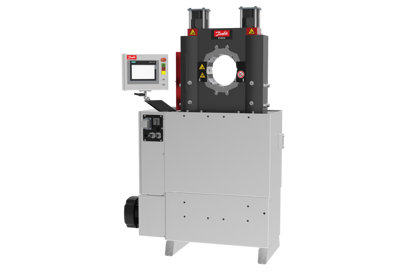

Wide and strong

With a wider opening and a stronger crimping force than other workshop machines, the ET4500 offers a capacity that’s almost at the level of production machines, but at a much lower cost. The ET4500 is designed to crimp hydraulic hose assemblies up to 2”, including R15 spiral hoses up to size -32, and industrial hose assemblies up to 3”. Available with an optional controller.

Features and benefits

Top capacity workshop machine enables assembly of big sizes and spiral hoses

Optional controller with Danfoss crimp specifications, our controller enables easier and faster crimping

Slide bearing technology

Fixed 6-o’clock die

Large opening

Low noise & ergonomic design

CE compliant, recommended for Europe, Middle- East and Africa

Product range

-

if (isSmallPicture) {

ET4300 and ET4350 workshop crimping machine

ET4300 and ET4350 workshop crimping machineCombining the benefits of a cost-effective small workshop machine with the versatility to manufacture a varied range of hose and fitting configurations thanks to solid master dies, the ET4300/ET4350 crimper is an unrivalled leader in the 1¼” field.

-

if (isSmallPicture) {

ET5070 production crimping machine

ET5070 production crimping machineDesigned for operator safety, improved ergonomics, increased hose size capability, ease of use, and maximum productivity, the ET5070 can meet almost any challenge across a broad range of hose sizes and construction types.

-

if (isSmallPicture) {

ET4200 and ET4250 workshop crimping machine

ET4200 and ET4250 workshop crimping machineThe ET4200/4250’s compact construction allows for ergonomic working, while long master dies enable crimping of 90° elbow fittings up to 1¼”.

-

if (isSmallPicture) {

ET4400 workshop crimping machine

ET4400 workshop crimping machineDanfoss ET4400 crimper offers the higher force and larger machine opening needed to crimp large bore hose assemblies.

-

if (isSmallPicture) {

ET4100 manual crimping machine

ET4100 manual crimping machinePortable, cost-effective, and easy to use, the ET4100 is the perfect choice for field servicing. It also features the biggest opening in the market—enabling it to support more hoses than most manual crimpers.

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| User guide | Danfoss C.2 Control Panel User manual | English | Multiple | 29 Jul, 2024 | 3.0 MB | |

| User guide | ET4500-001 Crimper User manual | English | Multiple | 26 Jul, 2024 | 3.3 MB | |

| User guide | ET4500-002 Crimper User manual | English | Multiple | 26 Jul, 2024 | 3.2 MB |

Related products

-

if (isSmallPicture) {

Marking machines and nipple inserters

Marking machines and nipple insertersOur tooling portfolio offers two embossing and marking machines that permanently imprint appropriate information onto hose assemblies—enabling easy identification as required by CE standards.

Our two robust and ergonomic nipple inserter enable faster and easier installation of even very heavy or bent fittings, accelerating productivity and delivering high-performance results. -

if (isSmallPicture) {

Hose saws, blades, cutting and skiving tools

Hose saws, blades, cutting and skiving toolsCleaner, safer cuts with less smoke and debris - Danfoss offers innovative saws, blades and precision cutting tools designed to ensure the success of your hose assembly operation. Modern blade technology for cleaner, safer cuts with smooth and dependable operation, though robust construction of the saws with multiple blade options.

Related applications

-

if (isSmallPicture) {

Agriculture

AgricultureFarmers need agricultural machines that deliver the same high productivity every season. Hydraulic solutions from Danfoss ensure world-class performance from each machine, and a comfortable, stress-free working environment for their operators.

-

if (isSmallPicture) {

Construction

ConstructionSpace is limited on construction sites, and there are people working everywhere. Contractors need machines that can safely maneuver in a tight spot. At the same time they still need to be powerful enough to get the job done. At Danfoss, we deliver the components, software, and controls that enable your machines to run safely, efficiently and effectively.

-

if (isSmallPicture) {

Heavy machinery

Heavy machineryThink about the heaviest challenges in the open mining, road building and construction industry. Tasks such as cutting through rock or the Arctic permafrost; compacting thick layers of hot asphalt. As well as lifting huge, prefabricated wall panels into place.

-

if (isSmallPicture) {

Lawn and turf

Lawn and turfLawn and turf machines must adapt to their surroundings and the season – becoming sweepers or snow blowers as required. At Danfoss, we make hydraulic solutions to provide that flexibility and ensure safe and efficient operation.