Reliable operation and excellent ride comfort

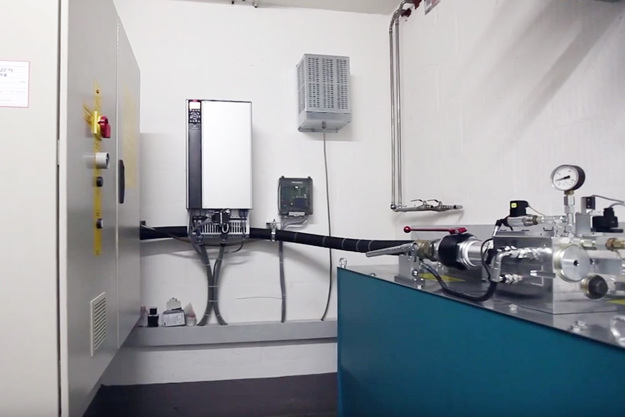

The VLT® Lift Drive is designed to provide reliable operation and excellent ride comfort for a minimum of 2.1 million cycles when running at an ambient temperature of below 45°C. Ideal for new projects or for retrofits, it operates without motor contractors and can be quickly and easily commissioned in less than 10 minutes.

Designed for all motors, including asynchronous, induction, permanent magnet, copper rotor and direct online PM motors, the VLT Lift Drive is suitable for both traction and hydraulic lifts in open- or closed-loop systems.

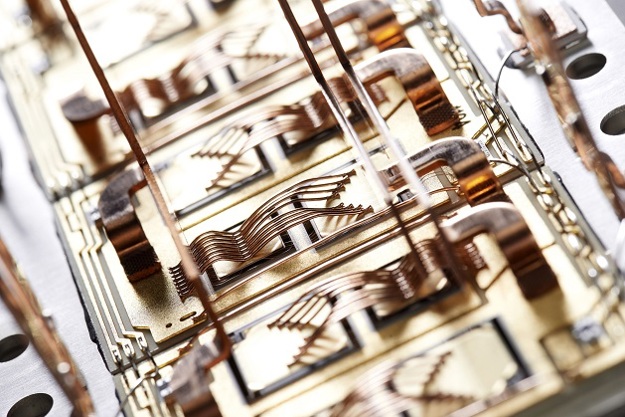

The compact design and intelligent cooling concept means it easily fits even into small installation spaces. And a range of built-in features eliminates the need for extra components. Scalable RFI filters minimize electromagnetic interference, integrated DC chokes suppress harmonics while ensuring the drives meet relevant EMC standards, and step-up, step-down transformers are not required.

Supply voltages and power range

- 380-400 V...4-55 kW

Features and benefits

Enhance travel comfort with our range of noise-reducing features

Use less energy with cooling fans that run only when required

Commission with no fuss since this drive fits all common feedback systems and there are just 10 parameters to set

Operate reliably in harsh conditions due to the specially coated circuit boards in this drive

Run reliably under intense vibration. Components remain firmly in place thanks to ‘ruggedization’

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Brochure | 9 Tips towards energy efficiency | English | Multiple | 09 Jan, 2023 | 79.2 MB | |

| Brochure | 9 Tips towards energy efficiency - Bulgarian | Bulgarian | Multiple | 02 May, 2023 | 73.1 MB | |

| Brochure | 9 Tips towards energy efficiency - Crotian | Croatian | Multiple | 30 Jan, 2023 | 73.1 MB | |

| Brochure | 9 Tips towards energy efficiency - Czech | Czech | Multiple | 21 Feb, 2023 | 73.1 MB | |

| Brochure | 9 Tips towards energy efficiency - Dutch | Dutch, Flemish | Multiple | 09 Jan, 2023 | 79.4 MB | |

| Brochure | 9 Tips towards energy efficiency - English US | English | United States | 14 Jun, 2023 | 77.8 MB | |

| Brochure | 9 Tips towards energy efficiency - Finnish | Finnish | Multiple | 20 Feb, 2023 | 73.1 MB | |

| Brochure | 9 Tips towards energy efficiency - French | French | Multiple | 09 Jan, 2023 | 79.4 MB | |

| Brochure | 9 Tips towards energy efficiency - German | German | Multiple | 09 Jan, 2023 | 79.4 MB | |

| Brochure | 9 Tips towards energy efficiency - Italian | Italian | Multiple | 30 Jan, 2023 | 73.1 MB | |

| Brochure | 9 Tips towards energy efficiency - Korean | Korean | Multiple | 03 Oct, 2023 | 73.2 MB | |

| Brochure | 9 Tips towards energy efficiency - Norwegian | Norwegian Bokmål | Multiple | 19 Jan, 2023 | 73.1 MB | |

| Brochure | 9 Tips towards energy efficiency - Polish | Polish | Multiple | 21 Feb, 2023 | 73.1 MB | |

| Brochure | 9 Tips towards energy efficiency - Romanian | Romanian, Moldavian, Moldovan | Multiple | 01 Mar, 2023 | 73.1 MB | |

| Brochure | 9 Tips towards energy efficiency - Slovenian | Slovenian | Multiple | 03 Apr, 2023 | 73.1 MB | |

| Brochure | 9 Tips towards energy efficiency - Spanish | Spanish, Castilian | Multiple | 29 Mar, 2023 | 73.1 MB | |

| Brochure | 9 Tips towards energy efficiency - Swedish | Swedish | Multiple | 18 Feb, 2023 | 73.1 MB | |

| Brochure | 9 Tips towards energy efficiency - Taiwan | Chinese (CN) | Taiwan | 11 May, 2023 | 73.3 MB | |

| Brochure | 9 Tips towards energy efficiency - Turkish | Turkish | Multiple | 02 May, 2023 | 79.2 MB | |

| Brochure | DrivePro Life Cycle Services - Chinese | Chinese (CN) | Multiple | 02 Apr, 2025 | 27.1 MB | |

| Brochure | DrivePro Life Cycle Services - Italian | Italian | Multiple | 01 Apr, 2025 | 26.7 MB | |

| Brochure | DrivePro® Services Overview | English | Multiple | 03 Feb, 2025 | 26.8 MB | |

| Brochure | DrivePro® Services Overview - German | German | Multiple | 28 Apr, 2025 | 26.7 MB | |

| Brochure | DrivePro® Services Overview - Portuguese | Portuguese | Multiple | 25 Mar, 2025 | 26.7 MB | |

| Brochure | DrivePro® Services Overview - Spanish | Spanish, Castilian | Mexico | 25 Mar, 2025 | 26.7 MB | |

| Brochure | DrivePro® Services Overview - US English | English | United States | 03 Feb, 2025 | 26.6 MB | |

| Brochure | Enjoy the ultimate in travel comfort - for elevator solutions in any power or voltage range | Czech | Multiple | 16 Mar, 2023 | 36.2 MB | |

| Brochure | Enjoy the ultimate in travel comfort - for elevator solutions in any power or voltage range | Russian | Multiple | 16 Mar, 2023 | 36.2 MB | |

| Brochure | Enjoy the ultimate in travel comfort - for elevator solutions in any power or voltage range | German | Multiple | 16 Mar, 2023 | 36.2 MB | |

| Brochure | Enjoy the ultimate in travel comfort - for elevator solutions in any power or voltage range | Chinese (CN) | Multiple | 16 Mar, 2023 | 34.8 MB | |

| Brochure | Enjoy the ultimate in travel comfort - for elevator solutions in any power or voltage range | Turkish | Multiple | 16 Mar, 2023 | 23.6 MB | |

| Brochure | Enjoy the ultimate in travel comfort - for elevator solutions in any power or voltage range | English | Multiple | 16 Mar, 2023 | 36.2 MB | |

| Fact sheet | Fact Sheet - VLT® Wireless Communication Panel LCP 103 Wireless connectivity to your drive | German | Multiple | 07 Mar, 2023 | 1.1 MB | |

| Fact sheet | Fact Sheet - VLT® Wireless Communication Panel LCP 103 Wireless connectivity to your drive | Danish | Multiple | 07 Mar, 2023 | 1.1 MB | |

| Fact sheet | Fact Sheet - VLT® Wireless Communication Panel LCP 103 Wireless connectivity to your drive | English | Multiple | 07 Mar, 2023 | 1.4 MB | |

| Fact sheet | Fact Sheet - VLT® Wireless Communication Panel LCP 103 Wireless connectivity to your drive | Romanian, Moldavian, Moldovan | Multiple | 07 Mar, 2023 | 1.5 MB | |

| Fact sheet | Fact Sheet - VLT® Wireless Communication Panel LCP 103 Wireless connectivity to your drive | Spanish, Castilian | Multiple | 07 Mar, 2023 | 1.1 MB | |

| Fact sheet | Fact Sheet - VLT® Wireless Communication Panel LCP 103 Wireless connectivity to your drive | Dutch, Flemish | Multiple | 07 Mar, 2023 | 1.5 MB | |

| Fact sheet | Fact Sheet - VLT® Wireless Communication Panel LCP 103 Wireless connectivity to your drive | French | Multiple | 07 Mar, 2023 | 1.5 MB | |

| Fact sheet | Fact Sheet - VLT® Wireless Communication Panel LCP 103 Wireless connectivity to your drive | Chinese (CN) | Multiple | 07 Mar, 2023 | 1.6 MB | |

| Case story | IBA Lift Drive | English | Multiple | 16 Mar, 2023 | 1.2 MB | |

| Case story | Lift Drive retrofit Scotland | English | Multiple | 17 Mar, 2023 | 3.5 MB | |

| Fact sheet | Remote LCP holder - English | English | Multiple | 09 Feb, 2023 | 630.1 KB | |

| Brochure | Ten things you need to know about Ecodesign | English | Multiple | 27 Feb, 2023 | 574.9 KB | |

| Brochure | Ten things you need to know about Ecodesign - Czech | Czech | Multiple | 27 Feb, 2023 | 906.0 KB | |

| Brochure | Ten things you need to know about Ecodesign - Danish | Danish | Multiple | 27 Feb, 2023 | 862.9 KB | |

| Brochure | Ten things you need to know about Ecodesign - Dutch | Dutch, Flemish | Multiple | 27 Feb, 2023 | 842.6 KB | |

| Brochure | Ten things you need to know about Ecodesign - Finnish | Finnish | Multiple | 27 Feb, 2023 | 865.0 KB | |

| Brochure | Ten things you need to know about Ecodesign - German | German | Multiple | 27 Feb, 2023 | 637.1 KB | |

| Brochure | Ten things you need to know about Ecodesign - Hungarian | Hungarian | Multiple | 27 Feb, 2023 | 902.8 KB | |

| Fact sheet | VLT Lift Drive | English | Multiple | 26 Jul, 2023 | 506.7 KB | |

| Fact sheet | VLT Lift Drive - German | German | Multiple | 20 Feb, 2025 | 1.4 MB | |

| Fact sheet | VLT Lift Drive - Turkish | Turkish | Multiple | 26 Jul, 2023 | 510.5 KB | |

| Fact sheet | VLT® EtherNet/IP MCA 121 | German | Multiple | 09 Aug, 2023 | 630.7 KB | |

| Fact sheet | VLT® EtherNet/IP MCA 121 | English | Multiple | 09 Aug, 2023 | 635.4 KB | |

| Operating guide | VLT® Lift Drive LD 302 | German | Multiple | 29 Jun, 2018 | 2.6 MB | |

| Operating guide | VLT® Lift Drive LD 302 | Swedish | Multiple | 20 Nov, 2017 | 2.5 MB | |

| Operating guide | VLT® Lift Drive LD 302 | Russian | Multiple | 06 Mar, 2017 | 3.6 MB | |

| Operating guide | VLT® Lift Drive LD 302 | English | Multiple | 04 Dec, 2013 | 2.9 MB |

Drawings

| Type | Name | Language | Updated | Download | File type |

|---|---|---|---|---|---|

| Eplan drawing | 130B1107_E-plan | 21 Mar, 2025 | 865.8 KB | .zip | |

| Eplan drawing | 130B1117_Eplan | 21 Mar, 2025 | 1.4 MB | .zip | |

| Circuit diagram | Wiring Schematic w-o Contactors FCD 302 | 25 Jan, 2025 | 284.8 KB | ||

| Circuit diagram | Wiring Schematic with Contactors FCD 302 | 26 Jan, 2025 | 284.2 KB |

Software

MyDrive® Suite provides all the software you need to select, integrate, program, and operate VLT® Lift Drive LD 302, in one place.

Related applications

Mid-range to high-rise residential and commercial building lifts, industrial site freight lifts, mine-shaft lifts, ‘recreational’ applications, such as ski lifts, boat lifts, aircraft lifts or elevators, vehicle lifts, walkways.

-

if (isSmallPicture) {

Drives for public and commercial elevators and escalators

Drives for public and commercial elevators and escalatorsAchieve high efficiency coupled with smooth, silent and safe operation of elevators and escalators, by applying variable speed control using AC drives.

-

if (isSmallPicture) {

Drives for residential elevators and escalators

Drives for residential elevators and escalatorsAC drives enhance elevator and escalator performance by ensuring reliable operation and high energy efficiency, combined with high comfort levels.

Case stories

-

if (isSmallPicture) {

Upgrade lifts energy efficiency by 58%

Upgrade lifts energy efficiency by 58%The VLT® Lift Drive breathes new life into an aged hydraulic elevator, transforming the agony of unstable operation to a smooth, quiet, comfortable experience. Extra bonus: the energy efficiency is remarkable!

-

if (isSmallPicture) {

Fast retrofit for maximum elevator uptime

Fast retrofit for maximum elevator uptimeResidents were pleased to avoid major inconvenience, when their apartment-block elevator broke down. Luckily VLT® Lift Drive provided a rapid fix.

-

if (isSmallPicture) {

Modernization optimizes travel efficiency and comfort

Modernization optimizes travel efficiency and comfortModernization to frequency-controlled hydraulic lift systems improves comfort and availability and reduces energy consumption by up to 60%.

-

if (isSmallPicture) {

Reduced installation costs at Fielmann Optics

Reduced installation costs at Fielmann OpticsThe VLT® Lift Drive used to control a new hydraulic lift saves energy, reduces installation costs and provides a smoother, faster, more comfortable ride.

-

if (isSmallPicture) {

Increased safety at Max Planc Institute

Increased safety at Max Planc InstituteThe dedicated VLT® Lift Drive with its patented safety application makes safety contactors omissible which significantly reduces installation costs.