Ammonia in industrial refrigeration

Environmental concerns and new F-gas regulation are forcing scientists and refrigeration technicians to take a serious look at natural refrigerants like air, water, ammonia, carbon dioxide and others as a long-term alternative for industrial refrigeration. Anyone involved in food preservation and industrial process plants already know ammonia as the refrigerant of choice due to its unmatched thermodynamic properties.

Having passed the test of time over more than a century as one of the best choices, ammonia is now receiving attention in areas of application where it was unthinkable earlier. Danfoss is a leader in ammonia refrigeration components, including manual, mechanic and electric valves. We are constantly working on developing components that enable safe and energy-efficient application of ammonia refrigeration.

Products for ammonia

See all our products developed for industrial refrigeration and ammonia.

-

if (isSmallPicture) {

ICV Flexline™ control valves

ICV Flexline™ control valvesDanfoss ICV Flexline™ guarantees you a reliable, safe and green solution - both now and in the future. The product family consists of an ICS pilot operated control, ICM motor operated control and ICLX 2-step solenoid valve.

-

if (isSmallPicture) {

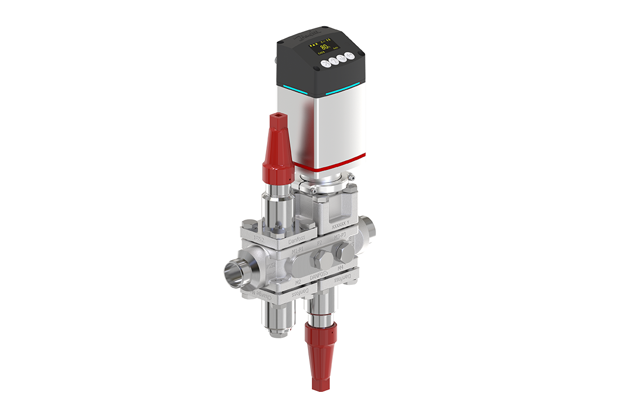

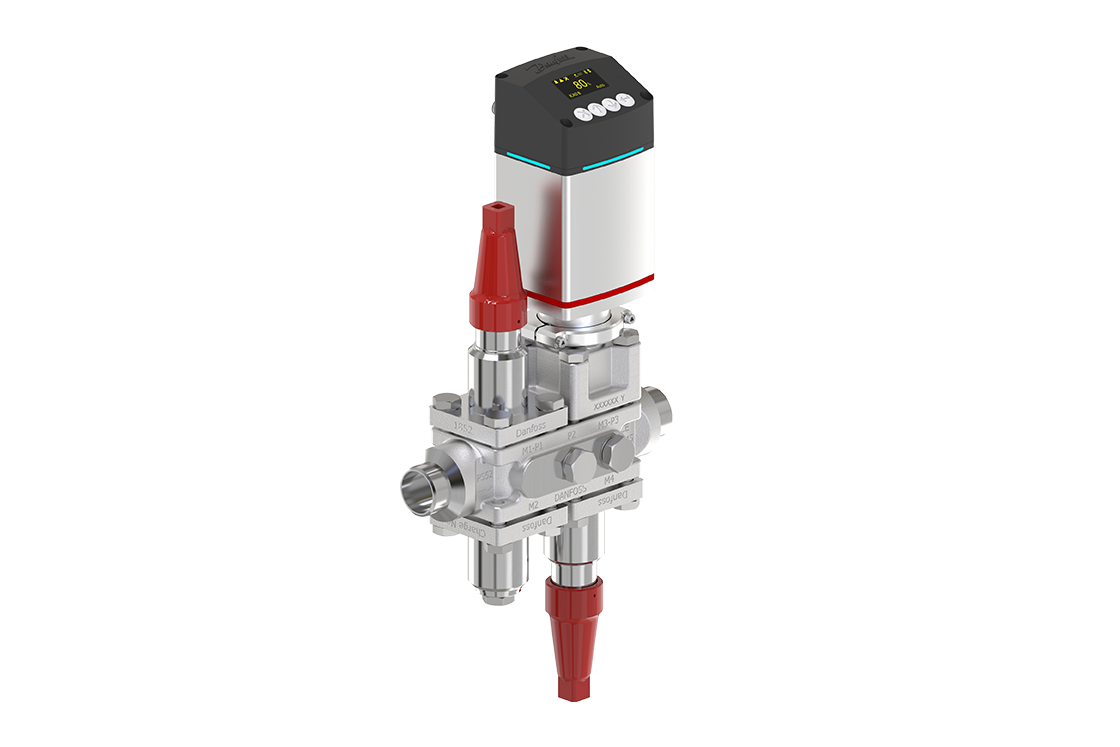

ICF Flexline™ valve station

ICF Flexline™ valve stationUnmatched freedom is the keyword of ICF Flexline™ valve stations. As part of the Flexline™ platform, these valve stations are based on a unique modular concept.

-

if (isSmallPicture) {

SVL Flexline™

SVL Flexline™SVL Flexline™ product platform targeted to meet industrial refrigeration requirements. The range cover five different functions with just two valve models.

-

if (isSmallPicture) {

Flexline™ platform

Flexline™ platformThe Flexline™ platform is synonymous with flexibility within industrial refrigeration. Based on a modular design concept, you will experience that each product features a variety of benefits, including easy selection, installation and maintenance.

Case studies

-

if (isSmallPicture) {

Hot gas defrost of low temperature refrigeration evaporators with natural refrigerants

Hot gas defrost of low temperature refrigeration evaporators with natural refrigerantsIndustrial refrigeration systems predominantly use natural refrigerants, primarily ammonia and more recently CO2 Energy efficiency and the effective operation of those systems are the key parameters for operators of the plants The focus of the white paper is the comparisons of hot gas defrost strategy control methods, both on the hot gas side as well as on the condensate drain

-

if (isSmallPicture) {

Ammonia conversion for cold storage facility is simple with ICV Flexline™

Ammonia conversion for cold storage facility is simple with ICV Flexline™Consumer retail stores are looking for tried-and-true ideas to thrive in turbulent economic times That’s why a major 190-store retail chain based in the Midwest switched to a proven refrigeration solution for one of its distribution centers - an environmentally friendly ammonia system that uses Danfoss ICV Flexline valve stations