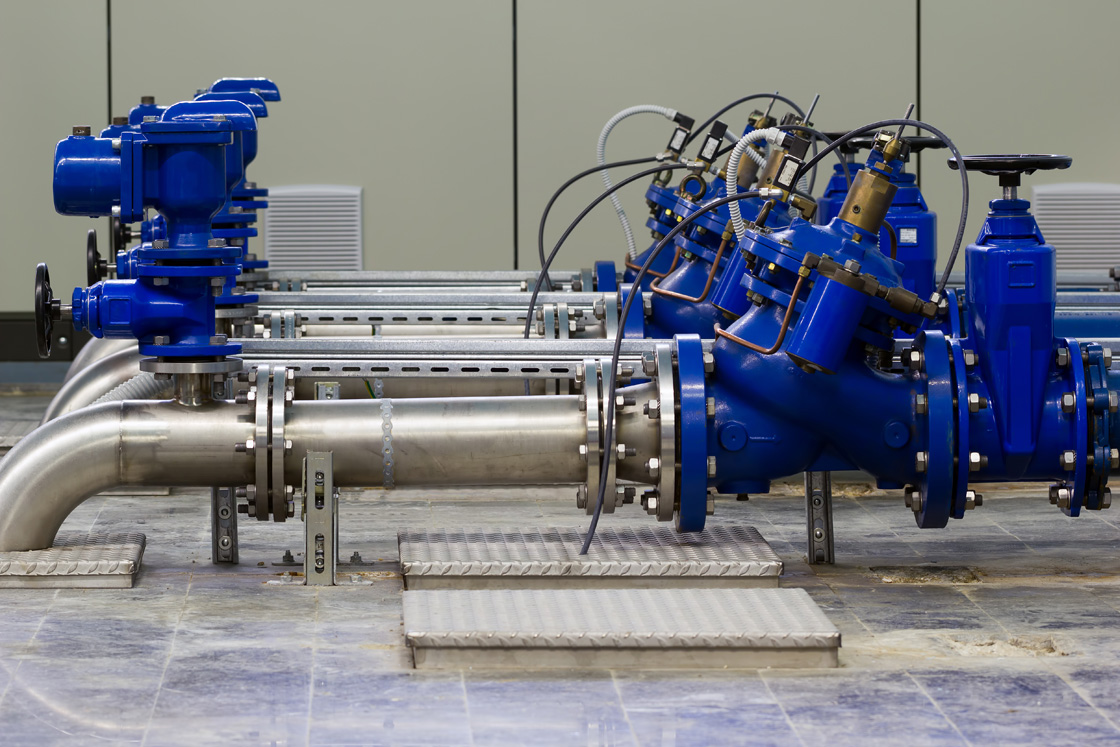

Ensure safe, reliable pump control for more efficiency and lower costs

By controlling industrial pumps with a Danfoss AC drive you can help optimize processes and significantly reduce energy and maintenance costs. The AC drive ensures that the pump exactly meets the demand and no more, operating at varying levels of part load instead of at maximum.

Safety is the highest priority in industrial pumping for the chemical industry, other process industries and heavy industries. Danfoss Drives has the knowhow and offering to make it easy for you to comply with regulations, for example, ATEX-certified temperature monitoring for EX motors and compliance to NAMUR recommendations.

Energy optimization and SCADA control of the industrial systems is also a fast-moving trend. By using Danfoss drives’ integrated deragging function, it is possible to improve pump efficiency by 15–30% and also drastically reduce maintenance costs.

Equipment protection

Another high priority in industrial environments is protection of your equipment from harmonics. Harmonics arise as the result of non-linear loads. There are several other sources of harmonics besides AC drives, and we are able to provide recommendation and services related to harmonics analysis and evaluations. Our products include chokes for harmonic reduction, and we offer passive and active solutions for harmonic mitigation.

Find exactly the right drive for your pump

You can find pump control for all your industrial pumping applications, in our wide range of low-voltage AC drives. The portfolio meets your power supply specifications, ranging from a fraction of a kW up to a few MW, and voltages from 230 V up to 690 V. The mounting possibilities cover many different requirements you may have: wall-mounted, modules for panel mounting and standardized enclosures with protection classes for different installation environments. Air- or liquid-cooling options are both available. For front ends, we also have a full range of choices: 6-pulse or 12-pulse rectifiers or active front ends.

The wide range of standardized enclosed drives offers a comprehensive selection of options for incoming sections as well as motor output. These options include, for example, contactors, fuses, switches and filters for dU/dt, common mode and sine wave. If our pre-engineered solutions don’t meet your requirements, we provide the possibility to tailor our cabinets to ensure we do meet your needs exactly.

Lifecycle services

To further optimize the performance of your industrial pumps, you can make use of our service portfolio, which covers the time before the start-up of equipment as well as the operation and maintenance of the AC drives. Our key services include customer support, engineering, extended warranty, start-up, maintenance, upgrade, spare parts and training.

30% energy reduction for Yamana Gold

Yamana Gold enjoys 30% energy reduction in energy consumption for its underground ventilation and pumping systems, thanks to VACON® drives.

Products

-

if (isSmallPicture) {

iC7-Automation

iC7-AutomationWhatever the environment, the iC7-Automation delivers the reliability and performance you need. With connectivity, security and intelligence, this drive lets you take advantage of the latest in Industrial IoT.

-

if (isSmallPicture) {

VLT® AQUA Drive FC 202

VLT® AQUA Drive FC 202VLT® AQUA Drive FC 202 controls all types of pumps and comes equipped with a cascade controller.

-

if (isSmallPicture) {

VACON® NXP Air Cooled

VACON® NXP Air CooledDesigned for a broad range of demanding applications, focusing on higher power sizes and system drives.

-

if (isSmallPicture) {

iC2-Micro

iC2-MicroThis next-generation micro drive gives you great cost effectiveness, durable reliability, and user-friendly commissioning and operation, all in a compact package.

-

if (isSmallPicture) {

VACON® 100 INDUSTRIAL

VACON® 100 INDUSTRIALDrive modules and enclosed drives that are easily integrated into all major control systems.

-

if (isSmallPicture) {

VACON® 100 FLOW

VACON® 100 FLOWDedicated functionality that improves flow control and saves energy in industrial pump and fan applications.

Case stories

-

if (isSmallPicture) {

Decarbonizing the dredge: Electrified high-pressure pump for horizontal drilling

Decarbonizing the dredge: Electrified high-pressure pump for horizontal drillingNETHERLANDS: B&P Electric Motors electrified its mobile high-pressure pump unit for horizontal drilling. VACON® NXP Liquid Cooled drives ensure high efficiency and resilience in harsh conditions, when forcing soil through pipes up to 3km long.

-

if (isSmallPicture) {

DrivePro® reduces cost, downtime, and failure rate for Dahe Paper Group

DrivePro® reduces cost, downtime, and failure rate for Dahe Paper GroupCHINA: Thanks to several Danfoss DrivePro® services, Dahe Paper Group, a state-owned paper mill company in China, has reduced its costs, downtime, and failure rate.

-

if (isSmallPicture) {

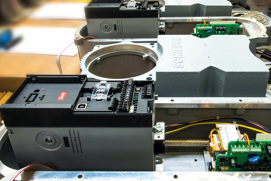

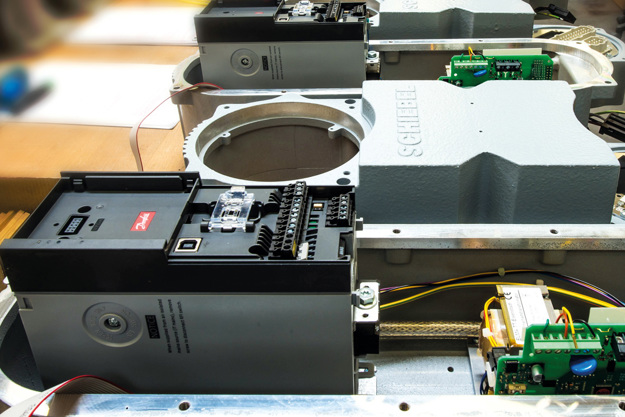

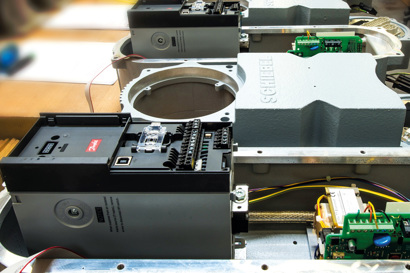

VLT® Midi Drive for precise actuator control

VLT® Midi Drive for precise actuator controlWith its compact and temperature-resistant design, the drive integrates easily into actuators from Schiebel Antriebstechnik GmbH, providing high-precision flow control.

-

if (isSmallPicture) {

Italcementi enjoys optimized process performance in all conditions

Italcementi enjoys optimized process performance in all conditionsItalcementi chose the VLT® AutomationDrive FC 302 to ensure optimized process performance in their harsh environments.

-

if (isSmallPicture) {

80 kW power savings at Kolomela mine

80 kW power savings at Kolomela mineBack-channel cooling in VLT® AutomationDrives reduces substation heat load enabling use of a smaller air-conditioning system with lower power consumption.

-

if (isSmallPicture) {

30% energy reduction for Yamana Gold

30% energy reduction for Yamana GoldVACON® AC drives improve the operation of underground ventilation and pumping systems and cut energy consumption of many application processes.

Contact us

For further information please contact us