A. Control Valves:

Factory fabricated pressure independent with internal differential pressure regulator (DPRV) which automatically adjusts to normal changes in system pressure and provides 100 percent control valve authority at all positions of the valve; maintain proportional/linear flow coil characteristics; and maintain a liner flow characteristic. The PICV shall accurately control the flow from 0-100 percent full rated flow with an operating pressure differential range of 3 to 60 PSIG, FCI 70-2 Class 4 shut-off on all sizes and field serviceable. Control valve shall incorporate control, balancing and flow limiting. Hydronic system pressure independent control valve bodies shall meet ASME B16.34 or ASME B16.15 pressure and temperature class ratings based on the design operating temperature and 150 percent of the system design operating pressure and shall have the following characteristics:

1. NPS 2 and Smaller: Class 150 bronze or brass body with union connections, stainless steel trim, stainless steel rising stem, stainless steel disc or ball, and screwed ends with back seating capacity repackable under pressure.

2. NPS 2-1/2 and Larger: Class 125 iron or ductile iron body, stainless steel trim, stainless steel rising stem, stainless steel disc or ball, flanged ends with back seating capacity repackable under pressure.

3. Pressure Control Seat: Brass construction with vulcanized EPDM.

Retain one or both sub-paragraphs below.

Maximum pressure drop of up to 5 psig (35 kPa) is usually acceptable. Show pressure drop on Drawings where critical.

4. Sizing: Line size.

5. Fittings and Components: All Fittings and Components shall meet ANSI standards and be totally compatible with readily available components in North America (except as allowed for 8” valves and above – Proper Companion Flanges must be supplied).

6. Close-Off (Differential) Pressure Rating: Combination of actuator, DPRV action, and trim shall provide minimum close-off pressure rating of 150 percent of total system (pump) head.

7. Valves shall be manufactured by one manufacturer throughout the project.

8. PICV’s shall be supplied by the PICV manufacturer only; “branded or 3rd party” PICV’s (those products which have been purchased from a manufacturer and labelled as manufactured by a supplier) are not acceptable.

B. Electronic Actuators:

Direct-mounted self-calibrating type designed for minimum 60,000 full-stroke cycles at rated force and shall be from the same manufacturer as the pressure independent control valve; branded or 3rd party actuators must be submitted and approved prior to bid. The actuator shall provide visible position indication. Fail positions on power failure shall include in-place, open or closed as noted in the ATC / BAS controls specifications.

Coordinate first subparagraph and list below with Part 2 "Manufacturers" Article. Retain "Available" for non-proprietary and delete for semi-proprietary specifications. If list does not include manufacturers of systems that make or market this equipment under their own name, those manufacturers' names may be added. List can be deleted if it is not important that specific manufacturers be named for this product.

1. Valves: Sized for maximum circuit flow rate, generally line sized.

2. Actuator to Coil Characteristics: Actuators shall be matched to provide the Heat Exchanger or Coil Characteristics of the product to be controlled – either Linear or Equal Percentage.

Actuators for Equal Percentage Characteristic coils shall be field set to Equal Percentage characteristics or possess built in adjustment features to provide an Alpha (α) Characteristic matching theα Characteristic of the coil or Heat Exchanger.

3. Overload Protection: Electronic overload or digital rotation-sensing circuitry.

4. Fail-Safe Operation: Mechanical, spring-return mechanism or Capacitance return. Power Requirements (Two-Position Spring Return): 24-V ac.

5. Power Requirements (Modulating): Maximum 10 VA at 24-V ac or 8 W at 24-V dc.

6. Proportional Signal: 0 to 10Vdc or 2 to 10-V dc or 4 to 20 mA, and 2- to 10-V dc position feedback signal.

7. Actuators for service above Ceilings shall possess UL listings and Approvals.

8. Temperature Rating: 40 to 104 Degrees F.

C. 3rd Party Test Results: The manufacturer shall submit in his submittal documentation package a set of 3rd Party test reports from a recognized testing agency verifying the accuracy and operation of the submitted valves and associated actuators. Separate reports for valves and actuators will not be acceptable.

D. Acceptable Manufacturers:

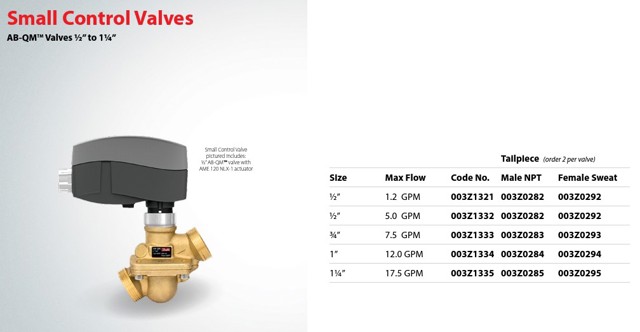

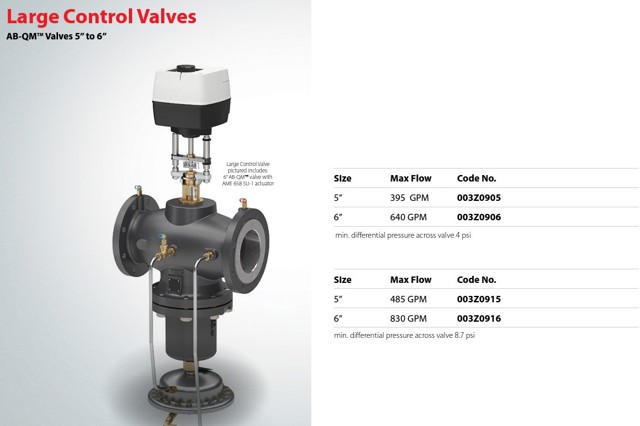

1. Base Bid: Danfoss AB-QM PICV valves

2. Alternate Deduct Manufacturer Bids may be Accepted with Approval by the Engineer Prior to Bid, including submission of 3rd Party Test Reports.