Discover how you can improve CAPEX and OPEX in mining and metals operations

No matter how well you have optimized your plant design, there is always a way to drive down costs even further. AC drives are used extensively for just that purpose, extending equipment lifetime, optimizing processes, reducing maintenance, and saving energy costs.

Save costs with VLT® and VACON® drives

Did you know that certain AC drives are designed for specifically the needs of mining and mineral processing plants; coping with extreme conditions, heavy loading, and controlling equipment installed a long distance away?

When using VLT® and VACON® drives, often you can even save on the cost of other equipment.

The growing world population and increasing volume of people moving to cities creates an ongoing need for new infrastructure and a continuous demand for mined resources. This is good news for the mining and metals industry. However, mine sites and mineral processing facilities and associated stockyards and port operations present some of the most challenging production environments.

Intelligent heat management and compact enclosures

It’s popular practice to install drives in relatively clean, pressurized, air-conditioned switch rooms and substations. However, this creates challenges as larger and more expensive air-conditioning systems could be needed to deal with heat loads. Thanks to the unique back-channel cooling design of higher power VLT® drives and VACON® liquid-cooled drives, heat loads are reduced enabling the use of smaller, lower-cost air-conditioning systems.

The sheer size of mining operations frequently means that cable lengths between drives and motors are long. Danfoss AC drives are designed to provide trouble-free operation with cable lengths up to at least 150 m for screened cables and 300 m for unscreened cables. As no additional output filters are required with these cable lengths, this saves space, installation time and costs compared to more traditional drive solutions.

Designed for harsh environments

Mining sites are often found in remote locations that are difficult to access, and harsh, dusty environments with extreme temperature ranges are common. For optimized up-time and reliable operations, it’s vital to have the right equipment installed and competent support readily available. Our world-leading after-sales service and support is available 24/7, no matter how remote your site is.

To optimize uptime and maximize drive lifetime, it makes sense to install a drive designed for harsh environments. Danfoss AC drives are compact and yet robust, and offer both energy-efficient design and low power losses. Available with coated PCBs, they operate reliably over decades of use in challenging conditions saving maintenance costs, ensuring better asset availability and providing you with the lowest cost of ownership. Modular medium-voltage drives are especially designed for rugged reliability in harsh environments.

Applications

-

if (isSmallPicture) {

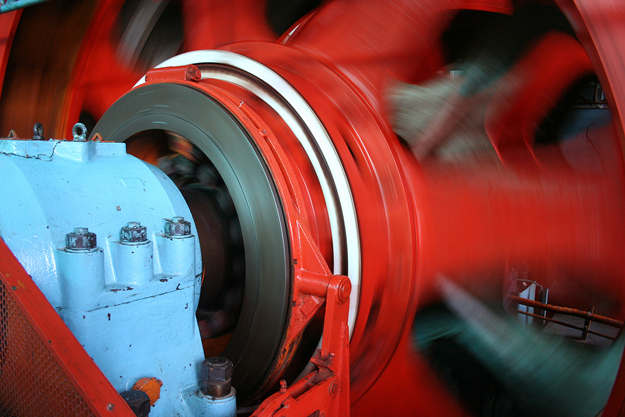

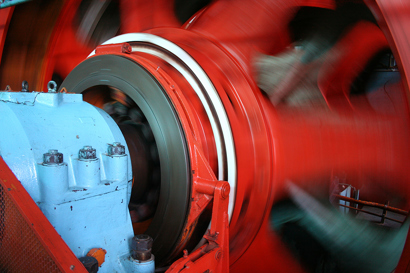

Drives for conveyors in mining

Drives for conveyors in miningFlexibility to control the speed of long conveyors can help optimize the complete system, reduce bottlenecks and extend motor lifetime.

-

if (isSmallPicture) {

Drives for cranes in mining and mineral processing

Drives for cranes in mining and mineral processingTo optimize crane and hoist performance, Danfoss offers flexible control strategies combined with energy efficiency, operating within stringent safety requirements.

-

if (isSmallPicture) {

Drives for mine ventilation fans

Drives for mine ventilation fansEnsure reliable and economical fan operation both at the surface and underground, with easy integration into Ventilation on Demand (VoD) systems.

-

if (isSmallPicture) {

Drives for pumps in mining

Drives for pumps in miningPumps perform a myriad of tasks throughout mining operations. By investing in performance optimization with Danfoss drives, you can achieve more efficient pumping, better equipment protection and lower operating costs in a lot of different areas.

-

if (isSmallPicture) {

Intelligent power conversion for smart grids

Intelligent power conversion for smart gridsBalancing supply and consumption is a complex task in a distributed smart grid, and this is where Danfoss supports you with certified power conversion solutions, saving you time, cost and effort in testing and certification.

-

if (isSmallPicture) {

Offshore oil and gas applications

Offshore oil and gas applicationsMaking up nearly 30% of global crude oil production, upstream Offshore Oil and Gas activities are some of the harshest operating environments on the planet. Drilling in waters up to 3,000 meters deep requires equipment that is reliable and safe to maximize operating productivity and prevent unexpected downtime.

Case studies

-

if (isSmallPicture) {

Addressing Dewatering Challenges at an Arizona Mine: VLT® AQUA Drive

Addressing Dewatering Challenges at an Arizona Mine: VLT® AQUA DriveWater presents a significant risk to mining operations, potentially causing equipment damage and environmental contamination. A robust pumping system is required to control the flow of water and remove it from the work site. A large copper mine in Arizona had reached a critical stage where they needed to replace their 250-horsepower (HP) dewatering pump and increase pumping capacity.

-

if (isSmallPicture) {

VACON® 1000 MV drives power deep pumping at Los Gatos mine

VACON® 1000 MV drives power deep pumping at Los Gatos mineMEXICO: Faced with the challenge of pumping stagnant water from depths of more than 400 meters, the Cerro Los Gatos mine opted for medium-voltage variable speed pump control using the VACON® 1000 drive from Danfoss. Drives were delivered and installed in the record time of 14 weeks from factory acceptance test.

-

if (isSmallPicture) {

Cement Plant Realizes Solid Energy Savings with Variable Frequency Drives

Cement Plant Realizes Solid Energy Savings with Variable Frequency DrivesHolcim (US) engaged Danfoss for advanced variable frequency drive technology to assist in making its manufacturing site one of the most energy-efficient cement plants in the world.

-

if (isSmallPicture) {

33 kW/h energy savings at Alaskan mine

33 kW/h energy savings at Alaskan mineWhen a VACON® NXS drive was installed on a test fan in this Alaskan mine, the energy savings equated to 33 kW/h or annual savings of USD 100,000 for generator power.

-

if (isSmallPicture) {

30% energy reduction for Yamana Gold

30% energy reduction for Yamana GoldVACON® AC drives improve the operation of underground ventilation and pumping systems and cut energy consumption of many application processes.

-

if (isSmallPicture) {

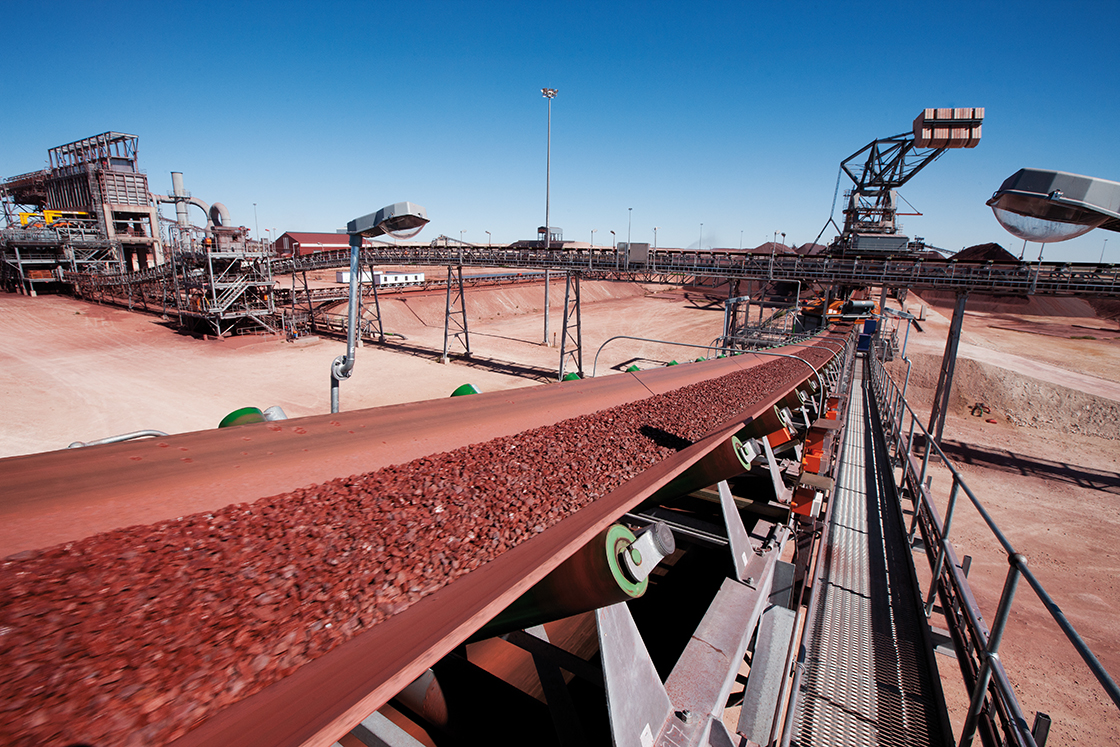

Minimal energy use at Shanxi Zhongxi Cement

Minimal energy use at Shanxi Zhongxi CementVLT® Drives move a 10.5-km-long conveyor belt. Load sharing between drives transfers energy from downhill segments to the uphill parts.

Danfoss Medium Voltage Drives

Learn more about the portfolio of Medium Voltage drives developed and produced at the Danfoss Drives facility in Research Triangle Park, North Carolina.

Related products

-

if (isSmallPicture) {

VACON® NXP Air Cooled

VACON® NXP Air CooledDesigned for a broad range of demanding applications, focusing on higher power sizes and system drives.

-

if (isSmallPicture) {

VLT® AutomationDrive FC 301 / FC 302

VLT® AutomationDrive FC 301 / FC 302The VLT® AutomationDrive FC301 / FC302 is designed for variable speed control of all asynchronous motors and permanent magnet motors. It comes in a standard version (FC301) and an advanced high dynamic version (FC302) with additional functionalities.

-

if (isSmallPicture) {

VACON® 3000 Drive Kit

VACON® 3000 Drive KitThis range of modular medium-voltage drives (MV drives) empowers systems integrators and OEMs, delivering a whole new approach to attaining the ultimate in performance, exactly tailored to the needs of each medium voltage drive application.

-

if (isSmallPicture) {

VACON® 3000 Enclosed Drive

VACON® 3000 Enclosed DriveReady-to-run medium-voltage drives offer a whole new approach to attaining the ultimate in performance and reliability. Select a standard enclosed drive to get up and running fast.