Built-in intelligence to keep your system running

Intelligence embedded in the VLT® AQUA Drive FC 202 automatically defines baseline parameters for water and wastewater applications, at all speeds and real-life operating cycles. In the event an issue is detected, Digital cascade control Hot Swap technology combined with back-up master functionality ensures reliable, stable and easy operation to help you stay up and running.

In addition to the features provide by the VLT AQUA Drive, Danfoss offers DrivePro®-tection which provides up to a 6 year on-site warranty to insure continued operation of your drive.

Superior performance for maximum results

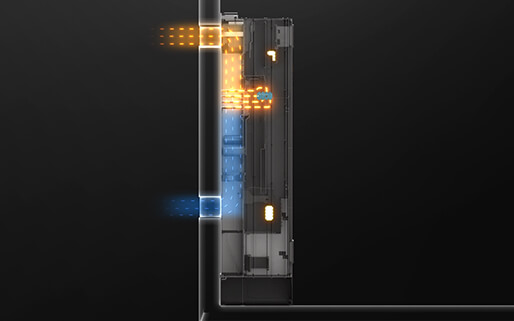

Energy saving heat management

A unique back-channel cooling concept transfers up to 90% of heat away from the room, using a fan-less design that exploits heat differentials in materials and air temperature and the latest developments in heat piping technology.

Our back-channel cooling system offers up to 90% reduction in your investment for air cooling systems to remove heat from the drives.

Integrated condition-based monitoring

Take motor and pump supervision to new levels with the intelligent VLT® AQUA drive.

Integrated condition-based monitoring lets you react quickly to critical situations like clogging, leaks, motor winding failure, vibration wear, mechanical misalignments and wear-out.

Cloud-free artificial intelligence embedded in the drive automatically defines operating baseline parameters corresponding to specific applications, at all speeds and real-life operating cycles. Reduced installation time and predictive maintenance lower operating costs and boost uptime.

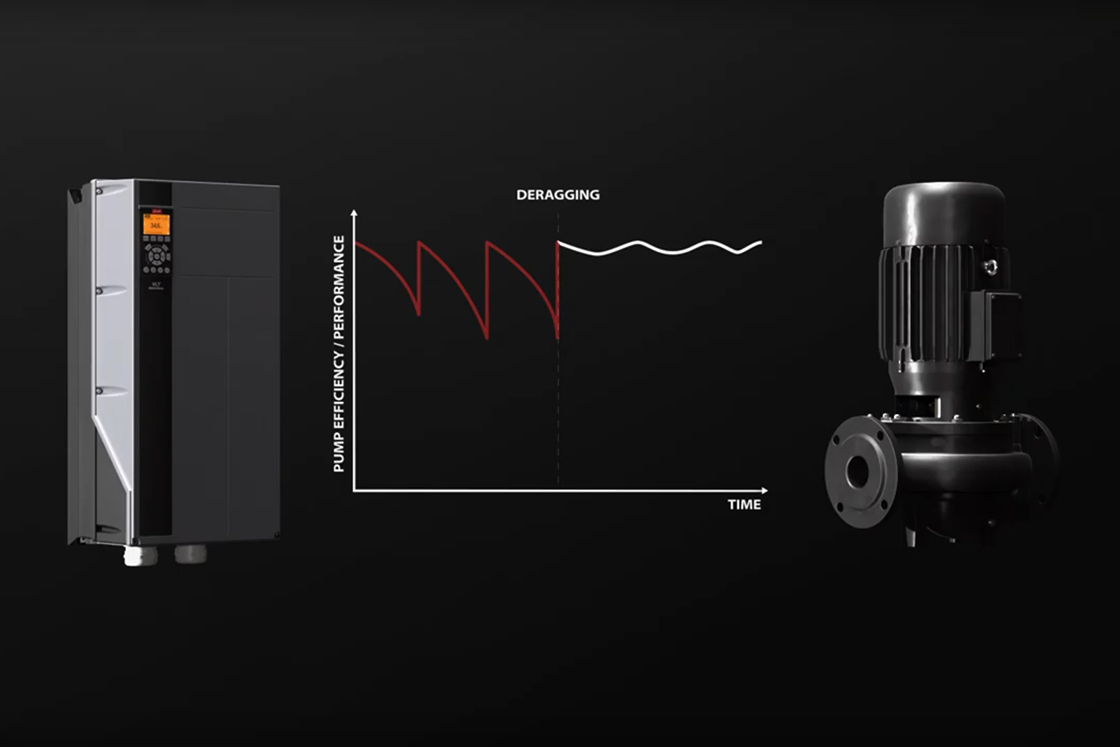

Deragging for consistently high pump efficiency

Embedded in the drive, the deragging function provides proactive maintenance with regular or clog triggered ‘wash cycles’ to keep impellers clean for consistently high pump efficiency.

Advanced harmonics mitigation

Danfoss offers efficient technologies to mitigate harmonics. See how our solutions can maximize efficiency.

Plant operators - see how you can take the pressure off

As a treatment plant operator, you know how critical a clean municipal water supply is for the health and safety of your community. Your days contain many obstacles that could put it at risk. By putting the right water treatment methods in place, you don’t have to worry either.

Applications

-

if (isSmallPicture) {

Drives for mixers, dewatering and blowers

Drives for mixers, dewatering and blowersUse AC drives to control the speed of motors in a wide range of pump, blower, mixer and dewatering applications to help enhance performance and value while saving energy and costs

-

if (isSmallPicture) {

Drives for water pumping

Drives for water pumpingFor water supply based on surface water or groundwater, Danfoss AC drives can help optimize the production process whilst reducing energy and maintenance costs.

-

if (isSmallPicture) {

Water and wastewater monitoring

Water and wastewater monitoringIn water and wastewater applications, activating a condition monitoring system integrated into your VSDs optimizes the overall performance. Edge computing means there is no need to connect to the cloud.

Success stories

-

if (isSmallPicture) {

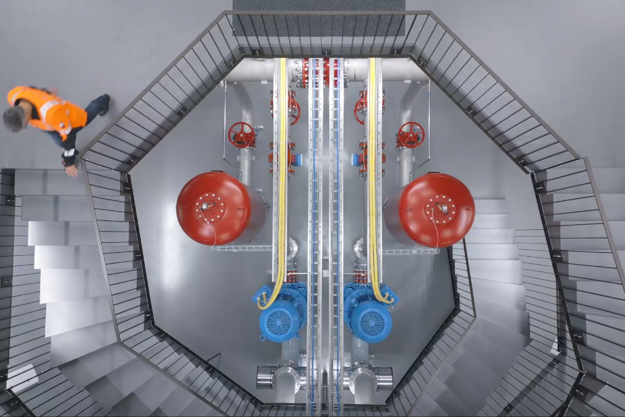

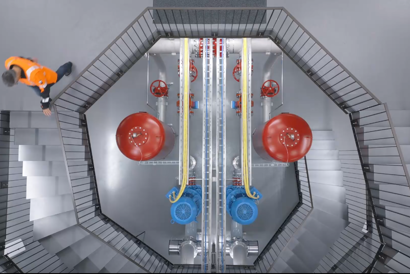

How a new water pumping station keeps supply flowing in Bern

How a new water pumping station keeps supply flowing in BernSWITZERLAND: The Wehrliau pumping station in Bern delivers up to 1.20 M liters of drinking water hourly. iC7 drives play a key role in ensuring reliable supply.

-

if (isSmallPicture) {

Keeping the Water Flowing with the VLT® AQUA Drive FC 202

Keeping the Water Flowing with the VLT® AQUA Drive FC 202In early 2023, the Warren County Utility District (WCUD) in middle Tennessee was faced with a dilemma. The water tank in their Short Mountain (SM) pressure zone required cleaning and repairs as part of federal compliance regulations, but with only one tank in the pressure zone, as is the case with many rural municipalities, they had few options to maintain water service to customers while the tank was out of service during the washout process and while repairs were completed. WCUD maintains a 4.0 MGD Water Treatment Plant, six storage tanks, four remote pump stations, into four pressure zones with approximately 650 miles of mains to serve 9,000 customers in rural portions of Warren and five adjacent counties.

-

if (isSmallPicture) {

Breaking the Pump Clog Cycle with Danfoss VFDs and Built-in Deragging

Breaking the Pump Clog Cycle with Danfoss VFDs and Built-in DeraggingThe Grand Strand Water and Sewer Authority in Myrtle Beach, South Carolina was struggling to keep up with demand at one of its main sewage pressure reducing stations. Myrtle Beach, a popular tourist destination, uses approximately 15 million gallons of water per day (MGD) or 5.5 billion gallons of water per year. The South Regional Pressure Reducing Station handles approximately 3 MGD and is controlled by suction pressure and a PID (proportional-integral-derivative) loop. Its purpose is to reduce pressure on the south side of the sewer district to enable the other stations to pump more.

-

if (isSmallPicture) {

Bringing clean drinking water to rural Kenya with 100% renewable resources

Bringing clean drinking water to rural Kenya with 100% renewable resourcesA solar-powered desalination plant in Kenya gives the community affordable, clean, and sustainable drinking water and irrigation water.

-

if (isSmallPicture) {

Jersey Water desalination plant boosts efficiency by 38%

Jersey Water desalination plant boosts efficiency by 38%For a recent major upgrade to its La Rosière desalination plant, Jersey Water chose VLT® AQUA Drive from Danfoss. With dedicated water-industry functionality, this drive provides outstanding harmonic performance and high efficiency.

-

if (isSmallPicture) {

Hospital selects DrivePro® programs to keep costs down, maintain efficiency

Hospital selects DrivePro® programs to keep costs down, maintain efficiencyAs the largest regional medical center in San Joaquin County, St. Joseph’s Medical Center in Stockton, Calif., has 359-beds, employs over 400 physicians and more than 2,400 employees. Operating the HVAC mechanical equipment for a facility this large is a huge energy-conservation challenge. That's why St. Joseph’s made the decision to use variable frequency drives (VFDs) on HVAC pump and fan motors —a decision that continues to pay off today, thanks to an innovative upgrade plan using Danfoss VLT® Drives.

Related water products

-

if (isSmallPicture) {

VACON® NXP Air Cooled

VACON® NXP Air CooledDesigned for a broad range of demanding applications, focusing on higher power sizes and system drives.

-

if (isSmallPicture) {

VACON® X5 HazLo

VACON® X5 HazLoVACON X5 HazLo is a first in the world of AC Drives. It has been certified for Class I; Division 2, Groups A, B, C, and D in a UL Type 4X enclosure.

-

if (isSmallPicture) {

VACON® X4/X5

VACON® X4/X5The VACON® X Series (X4 and X5) is a rugged family of variable speed AC drives, built and designed for harsh industrial environments.

For help selecting your successor product, try using MyDrive Assistant

-

if (isSmallPicture) {

VACON® 100 FLOW

VACON® 100 FLOWDedicated functionality that improves flow control and saves energy in industrial pump and fan applications.

-

if (isSmallPicture) {

VLT® Midi Drive FC 280

VLT® Midi Drive FC 280FC280 provides precise and efficient motor control for machine builders in the food and beverage, material handling and processing industries.