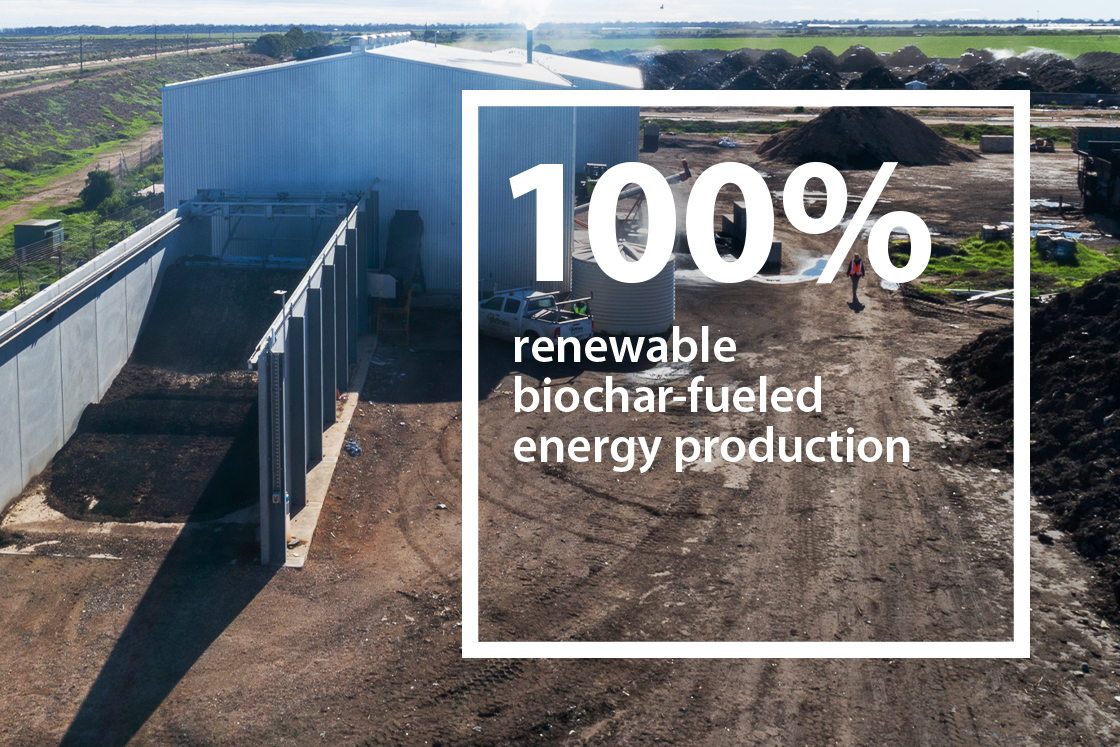

Adelaide, the capital city of South Australia, prides itself on being a leader in implementing citywide sustainable initiatives. And Jeffries Group, the region’s largest green waste processing facility, supports the city’s effort by converting waste from garden clippings, food scraps, timber, and liquid organics into enriched compost and soil. Driven by their commitment to being the link that keeps the recycling circle closed — and based on 70 years of experience — the team at Jeffries identified a huge opportunity. With the right technology, they could use the biochar byproduct of green waste to generate enough renewable energy to run their entire operation and feed surplus energy back into Adelaide’s power grid — with zero emissions.

First of its kind

Discover how the Danfoss VACON® NXP Grid Converter manages power in long-term partner gTET’s ORC generator — the technology behind Jeffries’ fantastic biochar power station and the first of its kind in Australia.

The challenge

Jeffries Group has taken the responsibility to be a leader in the renewable green waste market, setting new standards for more sustainable practices in the recycling industry — both on its home turf of Adelaide, South Australia, and across the globe.

With decades of market experience, the team saw an enormous untapped potential to build a power station that leveraged biochar, the charcoal byproduct of pyrolysis, to generate renewable energy that would power their operations — and supply Adelaide with surplus energy.

However, there were two clear challenges to overcome:

- Finding a high-performance solution backed by reliable technology

- Ensuring the solution had AS4777:2015 certification, a requirement to send surplus energy into Adelaide’s power grid

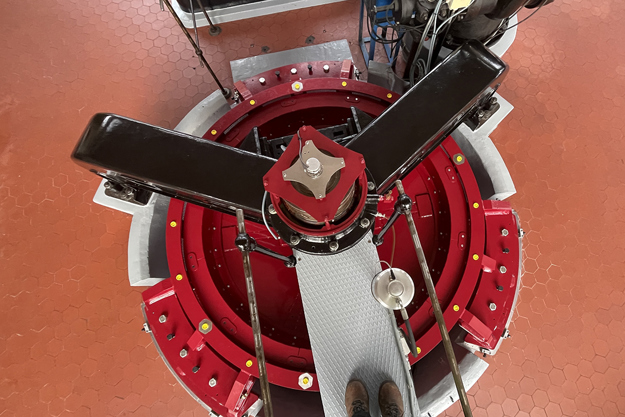

Danfoss Drives supported its long-standing partner and thermal energy management solution provider gTET with integrated VACON® drives — critical components in their Organic Rankine Cycle (ORC) generators.

“The VACON®-powered ORC generators are AS4777:2015 certified — and have enabled Jeffries to establish Australia’s first biochar power station with net zero emissions,” explained Paul Keen, Managing Director of gTET.

The solution

The Jeffries Group project began when gTET initiated the design and installation of an ORC generator. The generator’s technology creates a closed-loop thermodynamic cycle that uses exhaust heat from pyrolysis — the production of biochar from green waste — to generate electrical power.

Based on their market-leading high-speed regenerative capability, Danfoss VACON® drives are integral components in the operation of the ORC generator’s turbo-alternators. Several VACON® power converters were integrated into the system designed for the Jeffries Group:

- Two VACON® NXP Grid Converter units, type NXA 261 AFE

- 3 NXI 0385 inverters

- 2 NXI 0072 inverters

A certified connection

As part of an ongoing partnership with gTET, the VACON® NXP Grid Converter units obtained AS4777:2015 accreditation — making it possible for Jeffries Group to connect with Adelaide’s power grid. Because this certification was already in place, gTET could rely on a solution for the Jeffries Group that seamlessly met their rigorous needs.

“The VACON® drive solution manages the ORC generators’ turbo-alternator power — while meeting strict standards for performance and compliance,” said Keen.

The outcome

The Jeffries Group power station was commissioned in 2021. The new installation produces a commercial biochar product that is sold for agricultural soil — and it also generates 300kWe of power, significantly reducing the plant’s consumption from the main power grid. Furthermore, the installation produces at least 2GWh each year of power generation replacement from Adelaide’s main power grid — emission-free.

“The Jeffries Group biochar power station is the first of its kind in Australia — and is a model for how we can leverage energy-from-waste technology to generate renewable energy and build greener cities,” concluded Keen.

As an integral component to gTET’s high-performance ORC generator, the Danfoss VACON® NXP Grid Converter units delivered with high-speed regenerative capability, supporting the intense processes in the energyfrom-waste power station. And with the necessary certifications in place, Jeffries Group was able to act on their vision to build Australia’s first biochar power station.

Fueled by completely renewable resources, it is a model for how green waste can be transformed into energy — given a visionary mindset backed by high-performance technology.

More case stories

-

if (isSmallPicture) {

Unlocking efficiency with a drive retrofit at a Czech hydropower plant

Unlocking efficiency with a drive retrofit at a Czech hydropower plantCZECHIA: When 80-year-old gears were replaced by variable speed control at the Albrechtice hydropower plant, power production increased by 10%.

-

if (isSmallPicture) {

PSW and Danfoss: Flexible onshore power for berthed cruise ships

PSW and Danfoss: Flexible onshore power for berthed cruise shipsNORWAY & SWEDEN: PSW (Power and Automation AS) paired up with Danfoss to create compact OPS solutions in three Nordic harbors: Stockholm, Ålesund and Haugesund/Karmsund.

-

if (isSmallPicture) {

Revolutionizing green hydrogen production with Danfoss Drives

Revolutionizing green hydrogen production with Danfoss DrivesDENMARK: The Everfuel HySynergy facility produces green hydrogen with the help of iC7-Hybrid power converters for efficient, cost-effective electrolysis.

-

if (isSmallPicture) {

World’s first ferry powered by iC7-Marine: Aurora Botnia

World’s first ferry powered by iC7-Marine: Aurora BotniaFINLAND: The Aurora Botnia cargo and passenger ferry is equipped with a hybrid-electric propulsion system, powered by liquid-cooled iC7 drives from Danfoss.

-

if (isSmallPicture) {

Danfoss powers high-capacity SmartGrid energy storage

Danfoss powers high-capacity SmartGrid energy storageNETHERLANDS: Retaining 80% capacity after 8000 cycles, SmartGrid smart battery containers promise 21 years of daily discharge and recharge without performance concerns.

-

if (isSmallPicture) {

VACON® drives electrify passenger ferries in Oslo Fjord

VACON® drives electrify passenger ferries in Oslo FjordNORWAY: Electrification of the Nesodden ferries has reduced CO2 emission in the port of Oslo. VACON® drives and power converters play a key role onboard.