The Royal Navy’s Vanguard class is a class of nuclear-powered submarines. When they were introduced in 1994 they relied on distillation systems to provide ultra-pure water for the reactors and all other water for operations. Twenty years on, the Royal Navy needed to update the system.

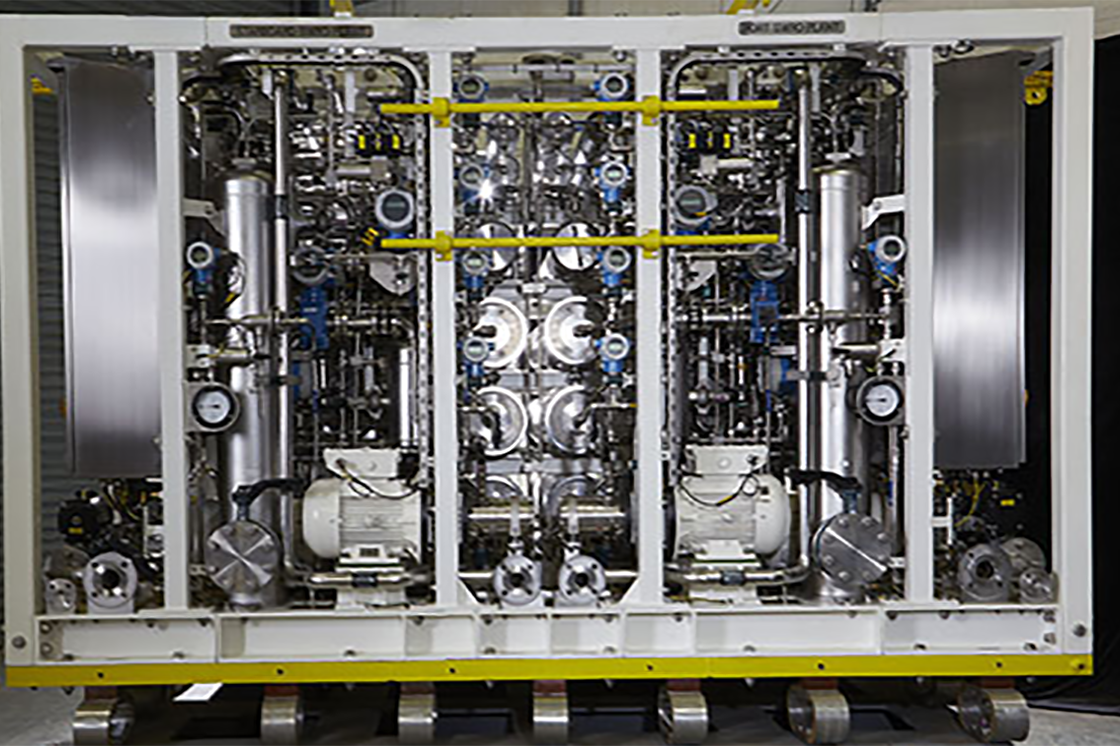

Salt Separation Services won the bid with a two-pass solution that featured Danfoss APP and PAHT pumps. The pumps’ compact size-to-output ratios, flexible configurability, and proven reliability were all key to winning the bid.

Related product

-

if (isSmallPicture) {

High-pressure pumps for SWRO applications

High-pressure pumps for SWRO applicationsThe range of high-pressure APP pumps is optimized for both landbased, off-shore and marine sea water reverse osmosis applications. Available with or without motor.

-

if (isSmallPicture) {

High-pressure pumps for ultra pure water applications

High-pressure pumps for ultra pure water applicationsHigh-pressure pumps for ultra-pure water applications i.e. with de-ionized, de-mineralized or distilled water. Appropriate for critical applications such as high-pressure cleaning and humidification. Available with or without motor.