Electrical noise

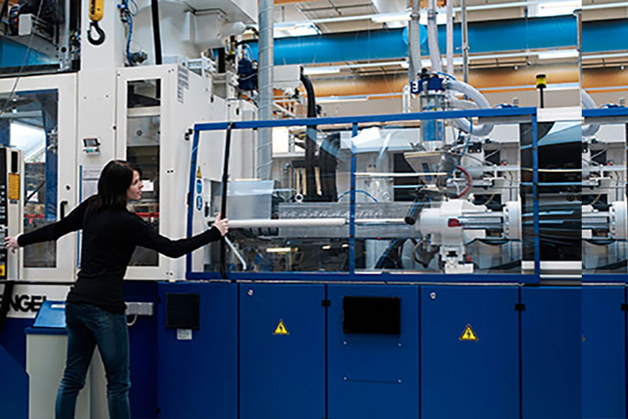

It can cause lost production hours, material waste and ultimately expensive damage and repair of machinery, if electric noise interferes with your plastic molding machinery. See how to avoid this.

Documents

Approvals

Related solutions

Learning

Learn more about our pressure transmitter range

Articles

Surf the productivity wave with fast and EMC-resistant pressure transmitters

The plastic industry is one of the world’s fastest growing industries. Competition is tough and to be at the forefront, equipment and processes must be top-tuned. Increasing consumer expectations to product quality and sustainable materials further fuel the development of next generation plastic processing machines.

Read more