Designed for Excavators

At the core of each Dextreme system is the Danfoss Digital Displacement pump, the first and only truly digitally controlled hydraulic pump for off-highway machinery. The pump's dedicated digital controller activates each piston individually, providing fast and accurate response to system demand, enabling superior machine controllability. The pump provides unmatched full and part load efficiency by using only the pistons needed to meet the load.

The incremental aspect of Dextreme systems minimizes risk for excavator OEMs now while positioning them as long-term leaders with a cost-effective system pathway to significant decarbonization.

Dextreme Pathway

Dextreme SWAP

- 15% reduction in energy use and CO2 emissions*

- Direct pump replacement

- Fuel saving mode and/or Productivity mode

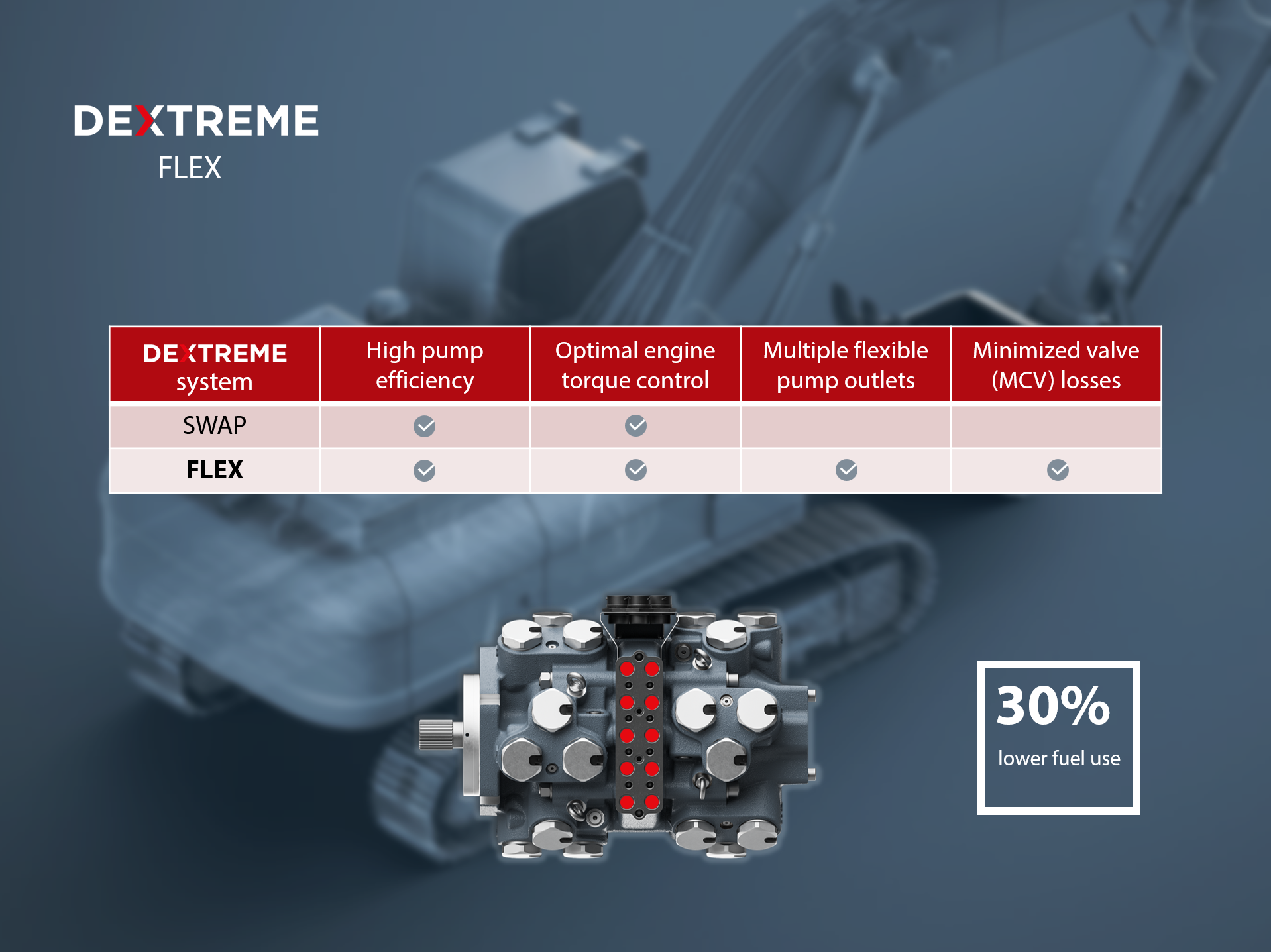

Dextreme FLEX

- 30% reduction in energy use and CO2 emissions*

- Minimized valve losses

- Built on Dextreme SWAP

Dextreme MAX

- 50% reduction in energy use and CO2 emissions*

- Ultimate hydraulic system

- Built on Dextreme FLEX

*compared to conventional excavator system

Product range

Dextreme SWAP

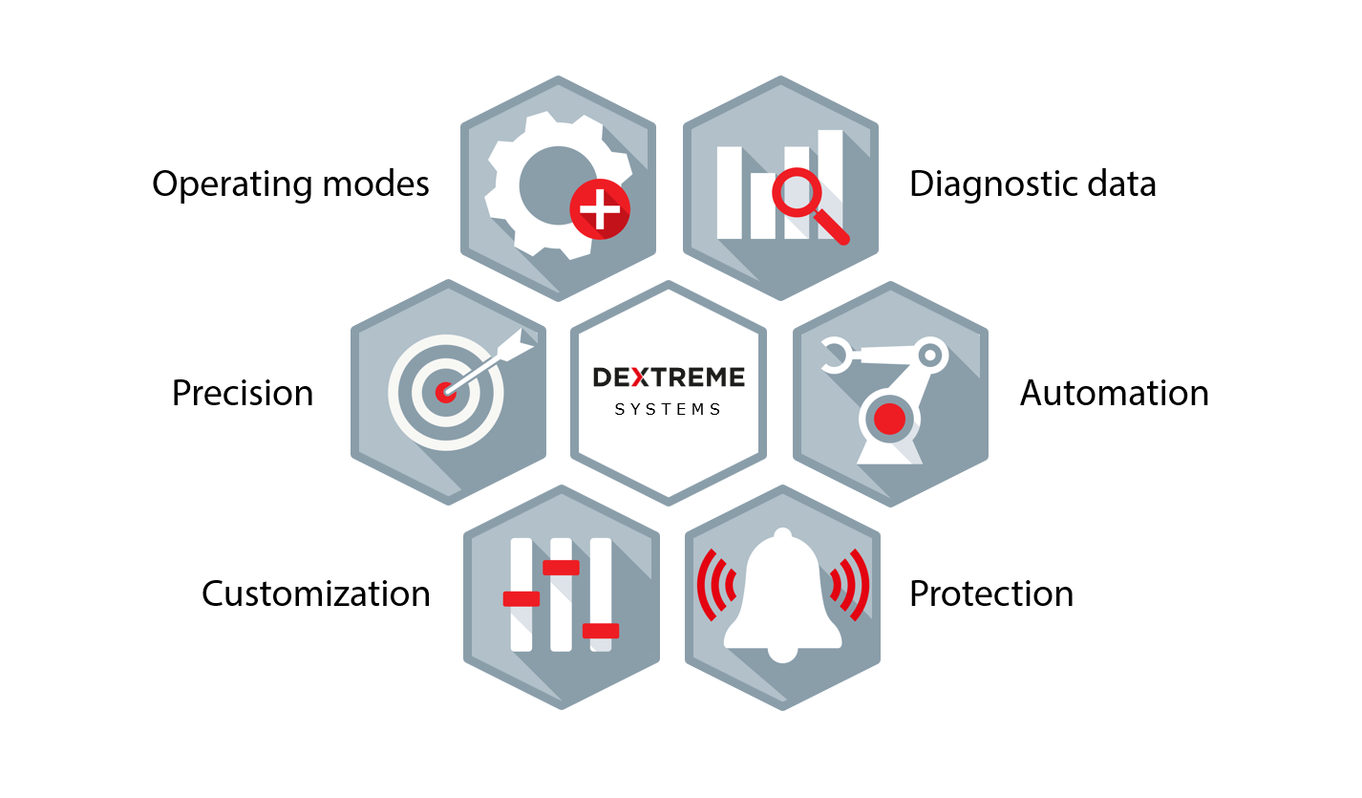

Dextreme SWAP offers software configurable excavator working modes – switchable at a fingertip. The fast response of the Digital Displacement® pump allows for optimal torque control of the engine.

More useful work can be done in Productivity mode. Or more fuel can be saved in Fuel saving mode by running the engine at lower speeds and without compromising on productivity.

Dextreme FLEX

With a Dextreme FLEX system, the Digital Displacement® pump (DDP) meets the hydraulic system demands of the excavator in the most efficient possible way. The flexible allocation of the DDP outlets results in minimized main control valve (MCV) losses.

In Fuel saving mode, Dextreme FLEX unlocks an unprecedented 30% lower fuel consumption in excavators – without compromising on productivity.

Reduce battery requirement by 24.8%

New research published by Danfoss Power Solutions shows that combining an electric motor with a Digital Displacement® pump in an excavator is the most efficient way to turn battery energy into hydraulic work.

News

-

if (isSmallPicture) {

Danfoss Power Solutions awarded £4.9 million grant to accelerate decarbonization of excavatorsThursday, September 14, 2023

Danfoss Power Solutions awarded £4.9 million grant to accelerate decarbonization of excavatorsThursday, September 14, 2023The grant is from the U.K. Government’s Department for Energy Security & Net Zero through the Red Diesel Replacement Phase 2 Competition, which provides funding for projects developing low-carbon alternatives to red diesel for the construction, mining, and quarrying sectors. Danfoss will use the funds to validate its Dextreme Max system in a 30-ton electric excavator, which it expects will reduce energy consumption by 50%.

-

if (isSmallPicture) {

Danfoss Power Solutions launches Dextreme systems pathway to increase excavator efficiency and productivityTuesday, March 28, 2023

Danfoss Power Solutions launches Dextreme systems pathway to increase excavator efficiency and productivityTuesday, March 28, 2023Dextreme systems improve excavator energy efficiency by 15% to 50%, regardless of the power source, while maximizing productivity. The Dextreme pathway consists of three incremental system solutions: Swap, Flex, and Max. The simplest configuration of the system, Dextreme Swap, is now available.

-

if (isSmallPicture) {

Field trial of new Danfoss Dextreme system in Volvo excavators expected to show greater productivity, reduction in fuel useTuesday, March 14, 2023

Field trial of new Danfoss Dextreme system in Volvo excavators expected to show greater productivity, reduction in fuel useTuesday, March 14, 2023U.K.-based building materials supplier Ashcourt Group to compare performance of three excavators fitted with Dextreme Swap system to standard excavators

People story

Our people have a passion to save energy.