Brazed plate heat exchangers featuring our unique Micro Plate™ technology

Experience superior heat transfer with our brazed plate heat exchangers featuring our revolutionary Micro Plate™ technology.

Compared to traditional fishbone plates, Micro Plate™ technology offers unparalleled heat transfer and energy efficiency. The technology has been meticulously designed for a wide range of applications, including heat pumps, chillers, district heating, and district cooling systems.

Discover the excellent performance of our brazed heat exchangers, offering a reliable and efficient alternative to existing brands in the market. With seamless compatibility, our heat exchangers provide a hassle-free solution for system upgrades or maintenance, ensuring optimal heat transfer.

The Micro Plate™ revolution

The unique and patented Micro Plate™ design, outperforms other solutions on the market with better thermal and hydraulic performance, significantly lower pressure drop and vastly improved heat transfer.

Enhanced heat transfer

The Micro Plate™ plate-pattern creates a completely new type of channel. The plates can be made very thin, due to the design and the number of contact points. The thin plates along with the strong turbulence created by the dimple pattern ensures the highest thermal performance.

In addition, the dimple pattern creates a nozzle-diffusor channel, which has bigger turbulence and less scaling than traditional fishbone channel. In the nozzle the velocity of liquid increases, and in the diffusor it decreases. That leads to local pressure oscillations inside the channel, which helps to thin down the boundary level and create bigger turbulence on the surface of the heat plate, preventing dirt to stick to the plates.

Better flow distribution

The improved water flow distribution in the Micro Plate™ design leads to an even velocity profile of the liquid, decreasing the number of stagnant zones on the plate. Minimizing the stagnant zones is essential to achieve high efficiency of heat transfer with a minimum loss of pressure. Optimized flow distribution areas allow the Micro Plate™ to effectively use the area around porthole for heat transfer, which increases the heat transfer area of each plate. Hence, the heat transfer area is almost equal to physical area of the heat plate.

Longer lifetime

The Micro Plate™ brazing points are flat, which increases the brazing area between the heat plates. This ensures that the pressure loads are distributed across a bigger area, which means higher strength and higher-pressure resistance compared to fishbone design.

Features and benefits of Micro Plates™

Up to 10% enhanced heat transfer efficiency

Increased lifetime

Substantial cost and energy savings

Better self-cleaning

More flexible and compact design

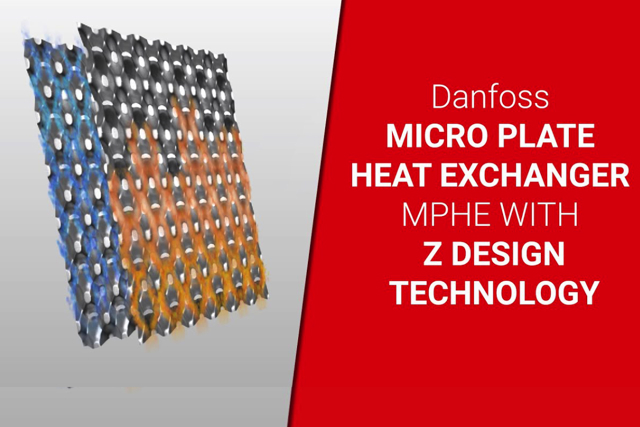

MPHE Z-design range of Micro Plate Heat Exchangers

Unleash the benefits of patented Danfoss Micro Plate technology in your chiller applications with high density refrigerants (R32, R410A, R454B) in capacity range from few kW up to 800 kW.

Micro Plate™ Z-series - a game changer for heat pumps and chillers

The secret behind the game-changing advantages of the Z-series lies in the use of the dimple-based design, which promotes an asymmetric Z-shaped flow of fluid across the plates. We’ve completely rethought the plate pattern and in so doing, pushed the performance of our heat exchangers to the limits. Not only does this maximize the heat transfer surface, but the liquid and vapor phases of the refrigerant also remain well mixed, ensuring even thermal contact with the water side of the system. As a result, it is possible to reduce refrigerant volume the and the same heat transfer capacity can be achieved with fewer plates, which reduces both raw material needs and product weight.

Z-design evaporators for chiller applications improve both resource and energy efficiency, enabling the creation of a new generation of state-of-the-art chillers. They contribute to the development of efficient building concepts that are set to become the norm in tomorrow’s sustainable cities.

The perfect component for high-efficiency A/C cooling systems, our Z-design evaporator MPHE series is game changer. Whether Z stands for zero, or for the millennial generation, or for the Z flow pattern of fluids across the heat exchanger plate, all of these are relevant. Using these heat exchangers, chiller manufacturers can achieve significantly better economic and environmental performance without compromising on either efficiency or capacity.

Using the same innovative technology all Z-design models have been created with both new buildings and retrofits in mind, anticipating rooftop and cellar-compact installations. In addition, the series is also suitable for new waste-heat recovery applications, such as heat transfer from data center chillers to district heating and cooling systems.

Key benefits of the Z-design pattern:

Higher heat transfer and energy efficiency

Minimal hold-up volume leading to less refrigerant charge and savings for installation costs

Reduction in both raw material needs and product weight

Reduction in both raw material needs and product weight

Suitable for several refrigerant options

Compatible with other Danfoss products and suitable for use in oil free systems

View the 3D models:

MPHE with Z design

MPHE dual circuit with Z design

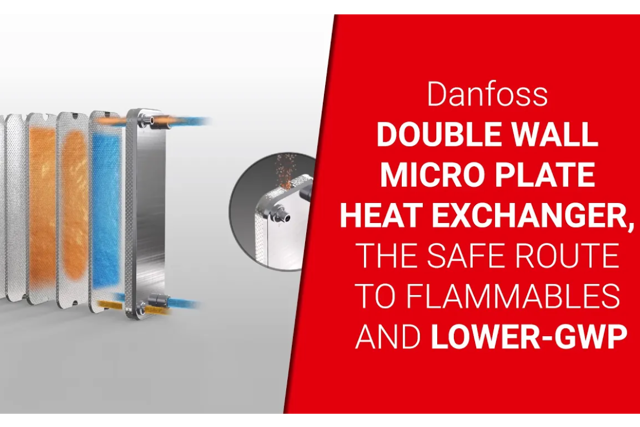

MPHE Double Wall

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Brochure | Z-design MPHEs for chillers Economic and environmental savings in cooling | English | Multiple | 23 Mar, 2023 | 2.4 MB | |

| Brochure | Z-design MPHEs for chillers Economic and environmental savings in cooling | Chinese (CN) | Multiple | 12 May, 2016 | 21.6 MB |

Videos

Software

HEXSelector: Heat exchanger design software

No matter if you have a chiller, a heat pump or a domestic hot water application, our heat exchanger software will allow the right heat exchanger selection by always ensuring you get the latest product range and software features at hand. To get access to our software, simply click on the link below and register.

Case stories

This Danish university is at the forefront of the refrigerant revolution with low-GWP scroll chillers

Advanced labs for education and research will put a high demand on the cooling system. Therefore, Danfoss and partner G.I. Industrial Holding are introducing one of the first chillers using the refrigerant R452B. It has some of the lowest Global Warming Potential for scroll systems available today.

Product range

-

if (isSmallPicture) {

Brazed plate heat exchangers for heating applications

Brazed plate heat exchangers for heating applicationsThe XB and SL range of copper brazed plate heat exchangers are ideal for use in District Heating (DH) and District Cooling (DC) applications

-

if (isSmallPicture) {

Brazed plate heat exchangers for cooling applications

Brazed plate heat exchangers for cooling applicationsBrazed plate heat exchangers with fishbone or Micro PlateTM plate technology offer a compact and flexible solution designed for ultra-efficient performance for your high-pressure or extreme-temperature applications.