For safe and efficient data center cooling

Cooling of IT equipment in data centres is an increasing challenge for operators and design engineers. Power management is the major challenge, with energy consumption and heat loads increasing in step with the server density. Meeting these challenges is essential for ensuring the safety and availability of the data.

Data center cooling technology:

Other important factors in data center cooling solutions are:

- Cost optimization: cooling can be up to 50% of the overall energy cost in a data center

- Precise humidity control and better control of static electricity

- Minimum start-up current for situations where the power grid is sensitive to load, reduced downtime, and increased lifetime of the overall system

Why choose our variable speed compressors for process cooling?

The first major benefit is the overall energy saving.

Other benefits include:

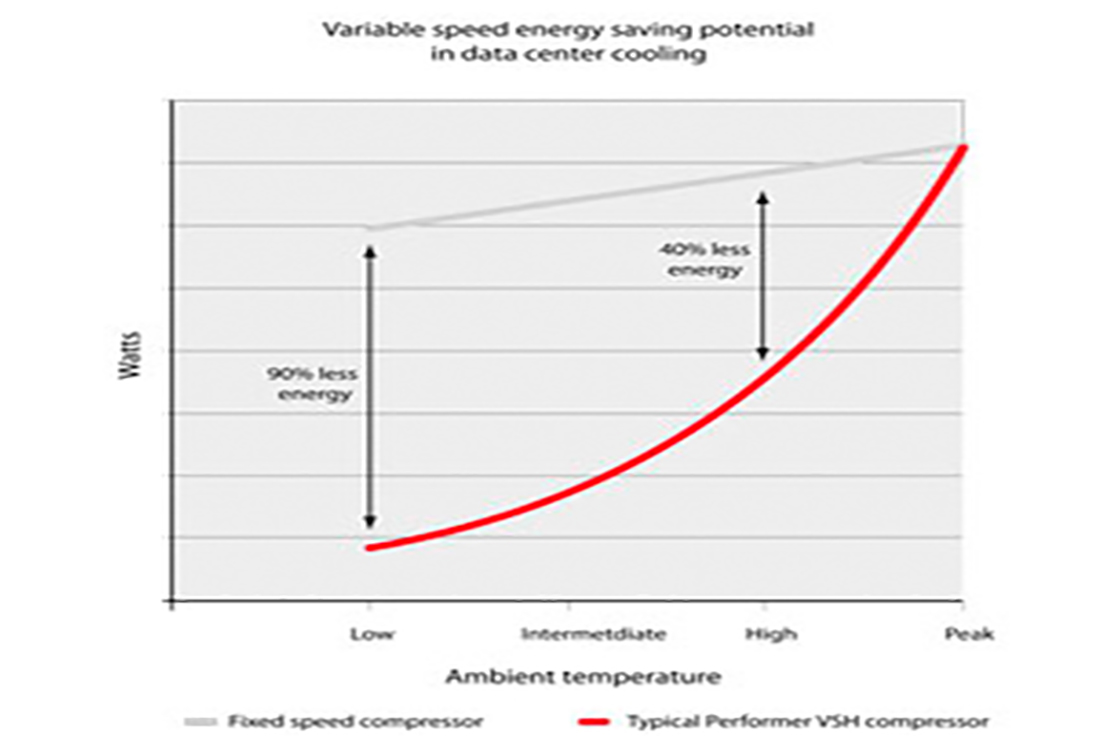

- Flexibility with combined compressor and free cooling

- Quick and smooth adaptation to varying loads; Danfoss inverter technology modulates cooling between 25 and 100%, saving substantial amounts of energy, especially in part-load operation. Experience shows that savings of up to 50% can be achieved in energy consumption. This significantly reduces the PUE values (ratio of power supplied to the data center divided by power consumed by the IT infrastructure) (see Figure 1).

Figure 1: Potential energy saving in a packaged unit equipped with a single inverter compressor compared with a unit equipped with a fixed-speed compressor.

- Actual energy efficiency improvements will vary depending on the data center design and the configuration of the cooling systems. However, recent experience has shown that installing a VSH variable speed compressor solution into a unit previously using traditional On-Off compressors can reduce the annual energy consumption of the cooling unit by as much as 50%. Danfoss inverter scroll compressors are the most energy-efficient solutions available on the market today.

- Stable and precise temperature control, with very consistent and stepless adaptation to required cooling load. Whatever the variation in ambient temperature or outside temperature, the system can maintain a set point temperature to within ±0.2°C thanks to the capacity modulation system (see below figures).

- Reduced noise under partial load conditions facilitates the integration of the unit in the surrounding.

- Reduced start-up current is an additional benefit with variable speed technologies, since the compressor rarely needs to start at full load, and since the Danfoss inverter has a very soft start with very low in-rush current. This benefit solves the problems that arise in areas where electric power is unstable, avoiding a peak in demand.

Products

-

if (isSmallPicture) {

Reciprocating inverter - VTZ

Reciprocating inverter - VTZDanfoss reciprocating inverter compressors avoid oversized and short cycling systems. The compressor automatically adapts to the current load. By combining an efficient Danfoss Maneurop® reciprocating compressor with a Danfoss Drive, the company provides an innovative and intelligent package that utilizes variable-speed technology to ensure superior efficiency across the entire operating range for precision cooling.

-

if (isSmallPicture) {

Inverter scrolls - VZH

Inverter scrolls - VZHDanfoss inverter scroll compressor VZH offers effectiveness and reliability. Over 30% energy savings is possible in rooftops, chillers, close controls etc.

-

if (isSmallPicture) {

Inverter scrolls - VRJ

Inverter scrolls - VRJDanfoss inverter scroll compressor solutions for commercial air conditioning and process-cooling applications. R410A, single units. VSH: first-generation commercial inverter scroll compressors with frequency converter CDS302. VZH: second-generation commercial inverter scroll compressors with frequency converter CDS303. VRJ: first high-tier residential inverter scroll compressors with frequency converter CDS801.

-

if (isSmallPicture) {

Inverter scrolls - VSH

Inverter scrolls - VSHDanfoss inverter scroll compressor solutions for commercial air conditioning and process-cooling applications. R410A, single units. VSH: first-generation commercial inverter scroll compressors with frequency converter CDS302. VZH: second-generation commercial inverter scroll compressors with frequency converter CDS303. VRJ: first high-tier residential inverter scroll compressors with frequency converter CDS801.

-

if (isSmallPicture) {

Turbocor® - TGS

Turbocor® - TGSDanfoss Turbocor model TGS oil free compressors are available in 5 different models ranging from 40 tons to 150 / 140 kW to 540 kW utilizing ultra-low GWP R1234ze or R515B.

Case stories

-

if (isSmallPicture) {

Denmark's new climate-friendly hospitality giant depends on Turbocor® oil-free chiller

Denmark's new climate-friendly hospitality giant depends on Turbocor® oil-free chillerThe new Alsik hotel in Southern Denmark sets a higher standard in energy-efficiency and is built to reach 76% CO₂-neutrality. A main contributor is the 900-kW chillers by Clint (a company of G.I. Industrial Holding) which features award-winning Danfoss Turbocor oil-free compressors.

-

if (isSmallPicture) {

Oil-free compressors maintain consistent performance over time

Oil-free compressors maintain consistent performance over timeDanfoss conducted a study to see how long term operation affected performance on Danfoss Turbocor® compressors. The results showed that oil-free, magnetic bearing compressors maintained consistent performance even after 10+ years of operation.

-

if (isSmallPicture) {

Wind power

Wind powerWind turbine producing water cooled by an energy efficient refrigeration system featuring inverter scroll compressor

-

if (isSmallPicture) {

Shopping malls

Shopping mallsInverter technology is improving one of the world's largest home DYI stores and helping gain Brazil’s first sustainability certificate with an innovative air conditioning installation.

-

if (isSmallPicture) {

Satellite launch towers

Satellite launch towersThe satellite launch tower is a vital facility. Reliable energy efficient inverter HVAC unit in this critical application was secured with Danfoss solution.

-

if (isSmallPicture) {

Process chillers

Process chillersVariable speed with Danfoss Turbocor Oil free centrifugal compressor guarantees reliable process cooling and efficient comfort cooling in factory

Contact us

For further information, please contact us.