Detect system failures and errors to avoid dangerous operation

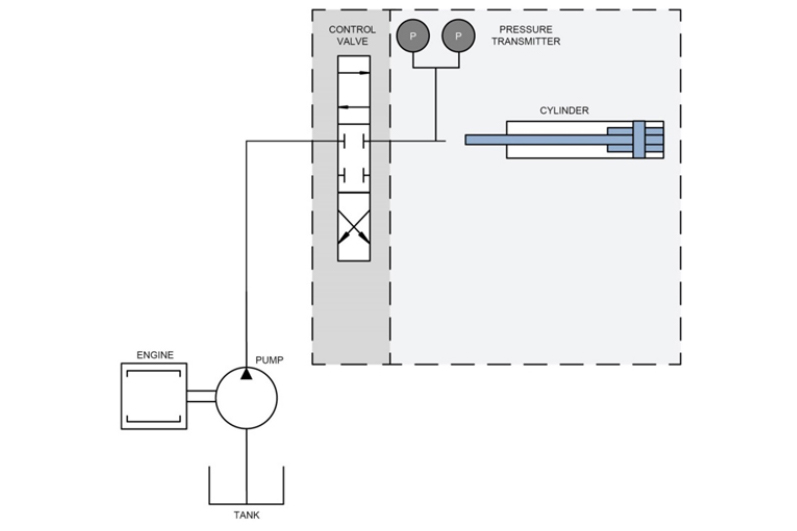

In machine control systems for cranes, lifting platforms and forklift trucks among others pressure transmitters are typically used. By the use of two pressure transmitters mounted on the main hydraulic cylinder system, redundancy is created in the system. The transmitter detects system failures and random error functions so that moving parts are shut down in case of dangerous operation and serious accidents are avoided.

Typical specifications

- Pressure range: 40 – 500 bar

- Temperature range: -40 – 125 °C

- Accuracy: 0.5% FS

- Response time typically < 1 mS

- Overpressure: 3 x FS

- Burst pressure: 10 – 20 x FS

Features and benefits

MTTFd, B10d and Mission time values

High burst and over pressure capabilities due to fully welded design

Resistant towards cavitation and liquid hammering

Good vibration and shock stability

Excellent EMC immunity

Zero drift due to excellent long term stability

Wide range of electrical and pressure connections

Wetted parts made of stainless steel

Functional safety sensor

Learn more about DST P92S SIL2 pressure sensor with built-in functional safety for mobile hydraulic applications.

Related products

-

if (isSmallPicture) {

MBS 1200 mobile hydraulic pressure transmitter

MBS 1200 mobile hydraulic pressure transmitterMBS 1200 series is a dedicated pressure transmitter program for mobile hydraulic applications.

MBS 1200 is a compact pressure transmitter, and offers a reliable pressure measurement, even under harsh environmental conditions. -

if (isSmallPicture) {

DST P92S SIL2, PLd pressure transmitter for mobile hydraulic

DST P92S SIL2, PLd pressure transmitter for mobile hydraulicEnsure functional safety in mobile hydraulic machinery with DST P92S SIL2 pressure sensors. When SIL2 or PL d is required for safe work environments.

Contact us

For further information, please contact us.