Flexibility and scalability

Onshore Oil and Gas activities require a great deal of flexibility and scalability. Due to that these are making up the majority of the world’s total oil production.

There is a variety of oil reserve types, and typically a much greater number of oil wells per reserve than offshore. Leading to that onshore equipment needs to be flexible and robust.

As unconventional drilling continuous to becomes a greater portion of the total onshore production, a wider range of equipment is needed than ever before. Minimizing the spend per well while maximizing efficiencies and production are critical in today’s market, and Danfoss can help.

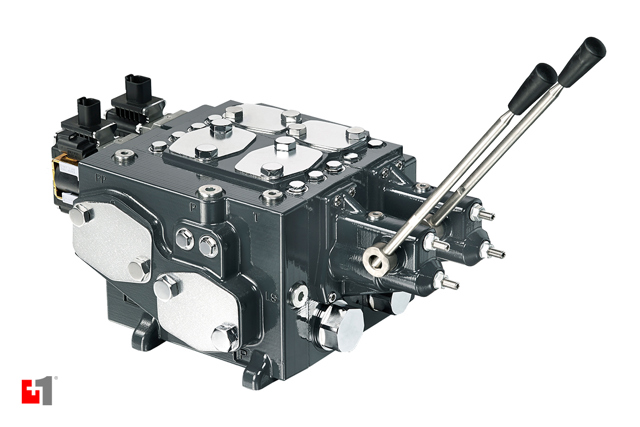

We understand the complexity of your equipment, and want to help. Let our hydraulic system design experts help you optimize your systems for flexibility, service, and performance. Flexible products such as the PVG family of valves allow us to customize a solution for your equipment. At the same time, providing the ability to actively monitor faults. This helps making it easier for you to ensure your equipment is operating properly. Simplify creating the control system for your wide variety of machines using our Plus+1 control package. Leading to that you can easily change your programs and allow for simple field service.

Related products

Related applications

-

if (isSmallPicture) {

Offshore oil and gas applications

Offshore oil and gas applicationsUpstream Offshore Oil and Gas activities are making up nearly 30% of global crude oil production. These are some of the harshest operating environments on the planet. Drilling in waters up to 3,000 meters deep requires equipment that is reliable and safe. this can help to maximize operating productivity and prevent unexpected downtime.